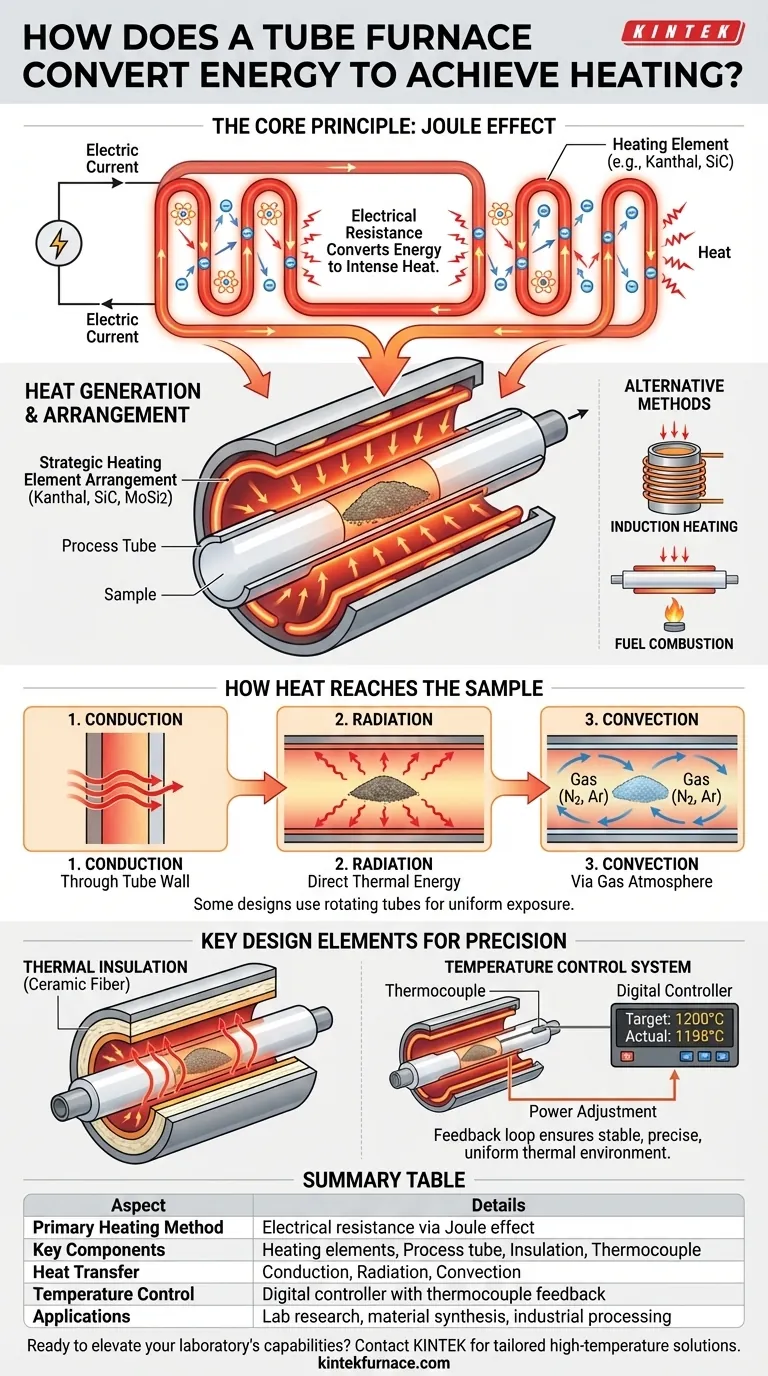

At its core, a tube furnace converts energy into heat primarily through the principle of electrical resistance. When an electric current is forced through specialized heating elements surrounding a central tube, the elements resist the flow of electricity, releasing that energy as intense heat—a phenomenon known as the Joule effect. This thermal energy is then transferred through the tube to heat the sample or material held inside.

A tube furnace is a high-precision heating system that generates heat around a process tube and then carefully transfers it inward. Its effectiveness lies not just in generating heat, but in precisely controlling and containing it to create a stable, uniform thermal environment for a sample.

The Core Principle: From Electricity to Heat

The most common method for heat generation in a modern tube furnace is elegant in its simplicity. It relies on converting electrical energy directly into thermal energy.

The Joule Effect in Action

The process begins when the furnace is powered on and a controlled electric current is sent to its heating elements. These elements are made from materials with high electrical resistance.

As electricity struggles to pass through these materials, the friction on an atomic level generates intense heat. This is the same basic principle that makes the coils on an electric stove glow red.

The Role of Heating Elements

Heating elements are the heart of the furnace. They are typically made of robust alloys like Kanthal (FeCrAl) or ceramic-based materials like silicon carbide (SiC) and molybdenum disilicide (MoSi2).

These elements are strategically arranged around the cylindrical furnace chamber, ensuring that the central process tube is bathed in radiant heat from multiple directions.

Alternative Heating Methods

While electrical resistance is most common, two other methods exist for specific applications:

- Induction Heating: Uses an electromagnetic coil to induce a current directly within a conductive crucible (often tungsten) inside the tube. This heats the crucible, which then radiates thermal energy to the sample. This method is exceptionally fast and efficient for specific materials.

- Fuel Combustion: In some large-scale industrial settings, a tube furnace may burn fuel like natural gas or propane. This is less common in laboratory environments due to the difficulty in achieving precise temperature control.

How Heat Reaches the Sample

Generating heat is only the first step. The critical second step is transferring that heat efficiently and uniformly to the sample inside the process tube.

Conduction Through the Tube Wall

The heat generated by the external elements must first pass through the solid wall of the process tube. This occurs via conduction, as thermal energy vibrates the atoms in the tube material, passing the energy inward.

The choice of tube material (e.g., quartz, alumina, or metal alloy) is critical, as it dictates the maximum temperature and the rate of heat transfer.

Convection and Radiation Within the Tube

Once the inner wall of the tube is hot, heat moves to the sample through two primary mechanisms:

- Thermal Radiation: The hot inner wall of the tube radiates thermal energy directly to the sample. This is a significant mode of heat transfer, especially at high temperatures.

- Convection: If the tube is filled with a gas atmosphere (like nitrogen or argon), that gas will heat up, circulate, and transfer heat to the sample through convection currents.

Some designs also incorporate a rotating tube, which tumbles the sample material to ensure every part is exposed to the heat source for more uniform processing.

Understanding the Key Design Elements

A pile of heating elements is not a furnace. The ability to achieve and maintain a precise, uniform temperature relies on crucial design components that manage heat.

The Challenge of Uniformity

Heat naturally wants to escape to cooler areas. The ends of the furnace tube are a primary source of heat loss, which can create an undesirable temperature gradient where the center is hotter than the ends.

The Solution: Thermal Insulation

To combat heat loss and improve efficiency, the entire heating chamber is encased in layers of high-grade ceramic fiber insulation.

This insulation traps thermal energy, minimizing the power required to maintain temperature and helping to concentrate the heat within the furnace cavity for better uniformity.

The Brain: Temperature Control Systems

Precise control is non-negotiable. This is achieved with a thermocouple feedback system.

A thermocouple is a temperature sensor placed near the heating elements or the process tube. It constantly reports the temperature to a digital controller. The controller compares this real-time reading to the user's setpoint and adjusts the power sent to the heating elements to maintain the target temperature with incredible accuracy.

How to Apply This to Your Goal

The method of energy conversion and heat transfer you need depends entirely on your material and processing objective.

- If your primary focus is precise, uniform heating for general lab work: Standard electrical resistance furnaces offer the best combination of control, reliability, and versatility for most research applications.

- If your primary focus is rapidly heating conductive materials: An induction furnace is superior, as it heats the material or crucible directly, bypassing the need for slower conductive and convective transfer.

- If your primary focus is bulk industrial processing at scale: Fuel combustion might be a cost-effective option, but it sacrifices the precise control essential for sensitive laboratory processes.

Ultimately, understanding how a furnace generates and manages heat empowers you to select the right tool for your specific scientific or industrial goal.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Heating Method | Electrical resistance via Joule effect |

| Key Components | Heating elements (e.g., Kanthal, SiC), process tube, insulation, thermocouple |

| Heat Transfer Mechanisms | Conduction through tube, radiation and convection inside |

| Temperature Control | Digital controller with thermocouple feedback for precision |

| Applications | Lab research, material synthesis, industrial processing |

Ready to elevate your laboratory's capabilities with tailored high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization ensures they meet your unique experimental needs for precise, uniform heating. Contact us today to discuss how our solutions can drive your research forward!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents