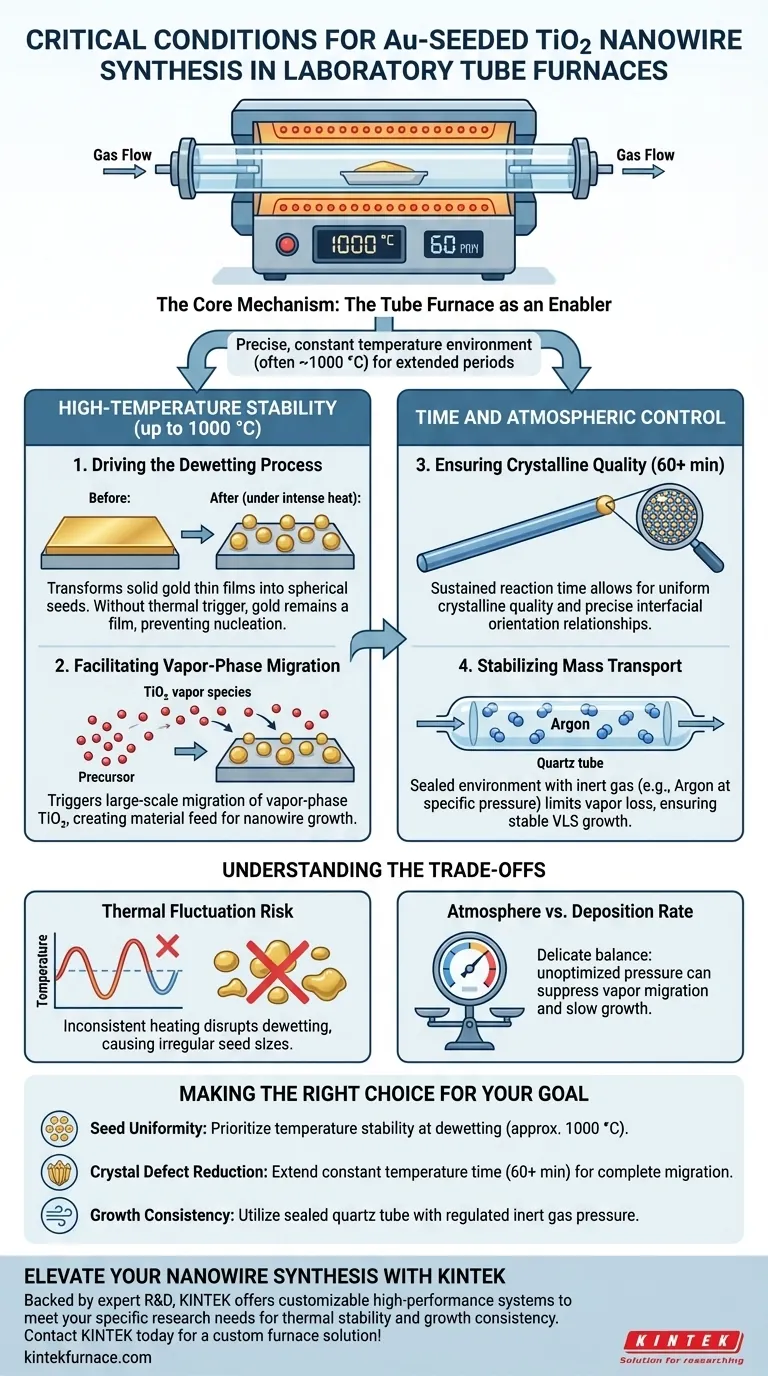

Laboratory tube furnaces are the critical enablers of the thermodynamic conditions required to synthesize Au-seeded TiO2 nanowires. Specifically, they provide a precise, constant temperature environment—often reaching up to 1000 °C—sustained over extended reaction periods, such as 60 minutes.

The Core Mechanism The tube furnace does not merely heat the sample; it acts as the primary driving force that transforms gold thin films into catalytic seeds and triggers the large-scale migration of TiO2 vapor. This precise thermal regulation is the deciding factor in the nanowire's final crystalline quality and structural orientation.

The Role of High-Temperature Stability

Driving the Dewetting Process

The most immediate function of the furnace's high-temperature capability (up to 1000 °C) is to alter the physical state of the catalyst.

Under this intense heat, solid gold thin films lose their structural continuity. They break apart and form spherical seeds through a process known as dewetting.

Without this precise thermal trigger, the gold would remain a film, preventing the nucleation necessary for nanowire growth.

Facilitating Vapor-Phase Migration

Once the seeds are formed, the furnace facilitates the movement of material.

The high thermal energy triggers the large-scale migration of vapor-phase TiO2 species.

This mobilized vapor travels to the gold seeds, creating the material feed required to build the nanowire structure.

Time and Atmospheric Control

Ensuring Crystalline Quality

The duration of the heat treatment is just as critical as the temperature itself.

Tube furnaces allow for long, stable reaction times (e.g., 60 minutes). This sustained energy input ensures that the crystalline quality of the nanowire is uniform throughout its length.

It also allows sufficient time for the establishment of precise interfacial orientation relationships between the seed and the nanowire.

Stabilizing Mass Transport

While temperature drives the reaction, the containment provided by the tube is essential for the Vapor-Liquid-Solid (VLS) growth mode.

Using a sealed quartz tube within the furnace creates a controlled environment, often utilizing inert gases like argon at specific pressures (e.g., 100 mmHg).

This sealed environment limits the loss of vapor-phase TiOx species, ensuring that the mass transport remains stable enough for consistent growth.

Understanding the Trade-offs

The Risk of Thermal Fluctuation

While tube furnaces offer high precision, even minor fluctuations in the "constant" temperature zone can be detrimental.

Inconsistent heating can disrupt the dewetting process, leading to irregular seed sizes rather than uniform spheres.

Atmosphere vs. Deposition Rate

There is a delicate balance between the pressure inside the tube and the growth rate.

A sealed environment prevents oxidation and material loss, but if the pressure is not optimized, it may suppress the vapor migration rate. This can result in slower growth or incomplete nanowire formation.

Making the Right Choice for Your Goal

To optimize your Au-Seeded TiO2 synthesis, align your furnace settings with your specific objectives:

- If your primary focus is Seed Uniformity: Prioritize precise temperature ramp-up and stability at the dewetting point (approx. 1000 °C) to ensure the gold film breaks into consistent spherical seeds.

- If your primary focus is Crystal Defect Reduction: Extend the constant temperature reaction time (60+ minutes) to allow for complete vapor migration and the settling of interfacial orientations.

- If your primary focus is Growth Consistency: Utilize a sealed quartz tube setup with regulated inert gas pressure to stabilize the VLS mass transport mechanism and prevent precursor loss.

Success in this synthesis relies on treating the furnace not just as a heater, but as a precision instrument for controlling phase transitions and vapor migration.

Summary Table:

| Critical Parameter | Function in Synthesis | Impact on Final Result |

|---|---|---|

| Temperature (up to 1000°C) | Drives dewetting of gold thin films | Formation of uniform spherical catalytic seeds |

| Reaction Time (60+ min) | Sustained energy input | Ensures high crystalline quality & structural orientation |

| Atmospheric Control | Inert gas (Argon) & pressure management | Stabilizes mass transport & prevents oxidation/vapor loss |

| Thermal Stability | Maintains constant temperature zone | Prevents irregular seed sizes & growth fluctuations |

Elevate Your Nanowire Synthesis with KINTEK

Precision is the deciding factor in crystalline quality. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific research needs. Whether you are optimizing gold seed dewetting or stabilizing VLS mass transport, our laboratory high-temp furnaces provide the thermal stability your project demands.

Ready to achieve superior growth consistency? Contact KINTEK today for a custom furnace solution!

Visual Guide

References

- Adel M. Abuamr, Guo‐zhen Zhu. Orientation Relationships and Interface Structuring in Au-Seeded TiO2 Nanowires. DOI: 10.3390/cryst15090766

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the horizontal design of these furnaces benefit large volume processing? Boost Efficiency and Uniformity

- How does a high-temperature tube furnace facilitate the sintering process of modified graphite felt? Precision Control

- What is the function of a tube furnace in palladium nanonetwork pretreatment? Unlock High Ductility and Zero Oxidation

- How does a multi-channel thermocouple array assist in measuring REBCO tape temperature? Master Thermal Uniformity

- Why is a high-purity argon environment required in a high-temperature tube furnace for ceramic scaffolds?

- What critical role does a laboratory tube furnace play in pBN-CTF synthesis? Master Molecular Engineering

- What is the importance of the calcination process using a tube resistance furnace? Optimize Boron Catalyst Activation

- What is the role of a three-zone tube furnace in HPHT nanodiamond pretreatment? Unlock Precise Surface Activation