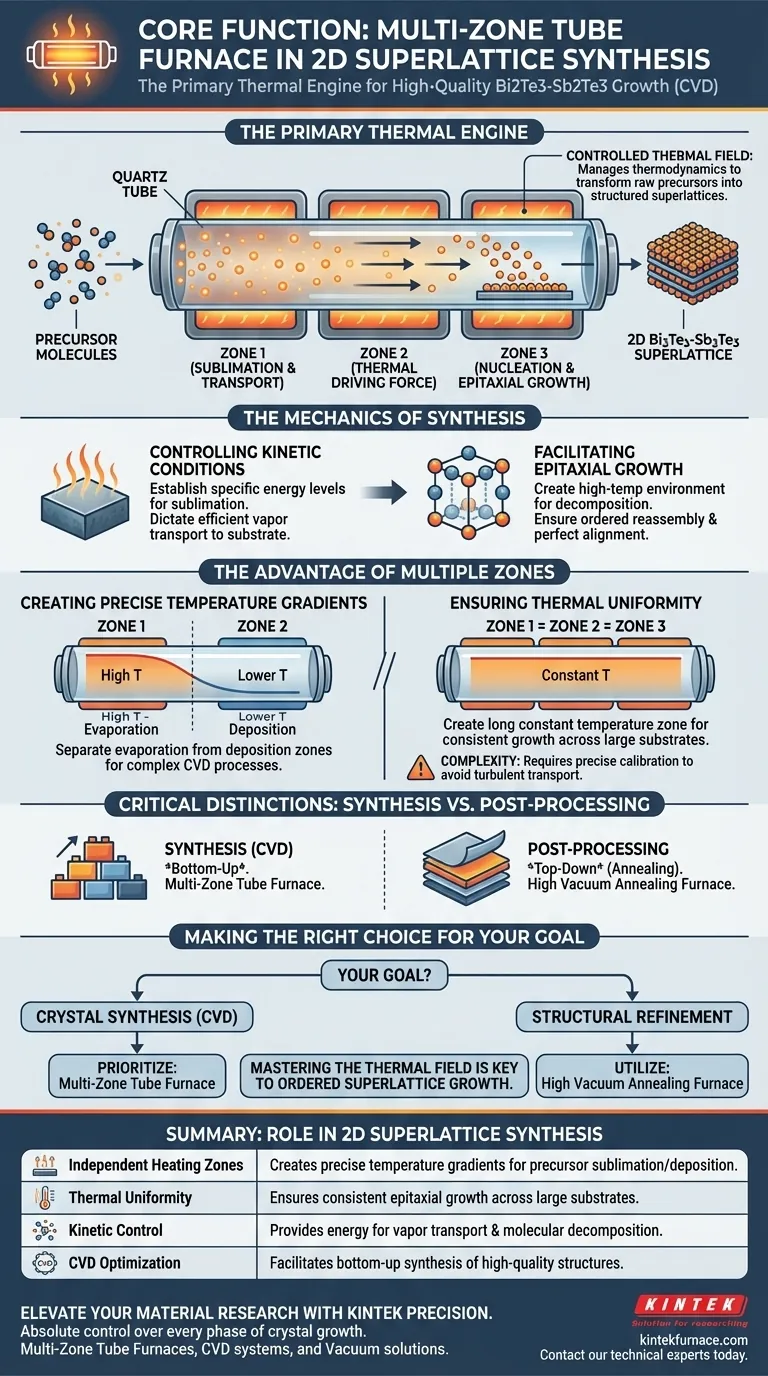

The multi-zone tube furnace functions as the primary thermal engine in the synthesis of 2D Bi2Te3-Sb2Te3 van der Waals superlattices. It provides the essential kinetic conditions required for the sublimation, transport, and nucleation of precursor molecules during Chemical Vapor Deposition (CVD). By maintaining precise high-temperature environments, the furnace facilitates the decomposition of precursors and their subsequent epitaxial growth onto the substrate.

The core value of this equipment lies in its ability to generate a controlled thermal field. It manages the complex thermodynamics of crystal growth, transforming raw precursor molecules into high-quality, structured superlattices.

The Mechanics of Synthesis

Controlling Kinetic Conditions

The synthesis of van der Waals superlattices requires more than just heat; it requires movement. The multi-zone furnace establishes the specific kinetic energy levels needed to sublimate solid precursors into vapor.

Once vaporized, these molecules must travel to the substrate. The furnace controls the thermal driving force that dictates this transport, ensuring the material moves efficiently through the reaction chamber.

Facilitating Epitaxial Growth

At the substrate level, the furnace creates a high-temperature environment that triggers the decomposition of the transported molecules.

This decomposition allows the atoms to reassemble in an ordered fashion. The precise thermal control ensures high-quality epitaxial growth, where the new crystal layers align perfectly with the underlying structure.

The Advantage of Multiple Zones

Creating Precise Temperature Gradients

Unlike single-zone heaters, a multi-zone furnace possesses independent temperature control capabilities for different sections of the tube.

This allows for the creation of specific temperature gradients. These gradients are often critical in CVD processes to separate the evaporation zone (where precursors turn to gas) from the deposition zone (where crystals grow).

Ensuring Thermal Uniformity

Alternatively, when a large growth area is required, multiple zones can be set to the same temperature.

This configuration creates a longer constant temperature zone than a standard single-zone furnace could achieve. This extended uniformity is vital for consistent film growth across larger substrates.

Critical Distinctions and Trade-offs

Synthesis vs. Post-Processing

It is crucial to distinguish the role of the multi-zone tube furnace from that of a high vacuum annealing furnace.

The tube furnace is used for the bottom-up synthesis (CVD) of the material. In contrast, high vacuum annealing is a top-down post-processing technique used to induce layer-by-layer thermal decomposition to fine-tune thickness.

Complexity of Parameter Control

The flexibility of multiple zones introduces complexity. Users must precisely calibrate the interaction between zones to prevent turbulent transport or premature nucleation.

Making the Right Choice for Your Goal

To maximize the effectiveness of your equipment in generating 2D Bi2Te3-Sb2Te3 structures, consider the following:

- If your primary focus is Crystal Synthesis (CVD): Prioritize the multi-zone tube furnace to establish the precise temperature gradients necessary for precursor transport and epitaxial growth.

- If your primary focus is Structural Refinement: Utilize a high vacuum annealing furnace to perform controlled thinning and layer engineering on pre-synthesized structures.

Mastering the thermal field is the single most important factor in transitioning from random deposition to ordered superlattice growth.

Summary Table:

| Feature | Role in 2D Superlattice Synthesis |

|---|---|

| Independent Heating Zones | Creates precise temperature gradients for precursor sublimation and deposition. |

| Thermal Uniformity | Ensures consistent epitaxial growth across large substrates in the constant temperature zone. |

| Kinetic Control | Provides the energy required for vapor transport and molecular decomposition. |

| CVD Optimization | Facilitates bottom-up synthesis of high-quality Bi2Te3-Sb2Te3 van der Waals structures. |

Elevate Your Material Research with KINTEK Precision

Achieving the perfect van der Waals superlattice requires more than just heat; it requires mastery over the thermal field. KINTEK provides industry-leading Multi-Zone Tube Furnaces, CVD systems, and Vacuum solutions designed to give you absolute control over every phase of crystal growth.

Backed by expert R&D and world-class manufacturing, our systems are fully customizable to meet the unique requirements of your advanced material synthesis. Whether you are performing bottom-up CVD growth or top-down vacuum annealing, KINTEK offers the reliability and precision your lab demands.

Ready to refine your synthesis process? Contact our technical experts today to find the ideal high-temperature furnace solution for your research.

Visual Guide

References

- Han Wang, Wen Lei. Superlattice Engineering on 2D Bi<sub>2</sub>Te<sub>3</sub>‐Sb<sub>2</sub>Te<sub>3</sub> Chalcogenides. DOI: 10.1002/advs.202503492

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does a horizontal tube furnace ensure experimental safety and accuracy during the thermal dehydrogenation of Ca(AlH4)2?

- What is the difference between a vacuum tube furnace and a standard tube furnace? Choose the Right Furnace for Your Lab

- What is the use of a quartz tube furnace? For High-Purity, Observable Material Processing

- What role do sealed quartz or glass tubes play in the synthesis of ternary copper sulfides? Mastering Micro-Reactors

- What makes horizontal furnaces suitable for high-performance production environments? Precision, Uniformity & High Throughput

- How does a high-temperature tube furnace ensure effective conversion during MOF selenization? Optimize Your Synthesis

- Why is it necessary to introduce high-purity nitrogen during tube furnace calcination? Ensure High-Performance La-EPS-C-450

- What additional features can tube furnaces have? Enhance Your Lab with Advanced Control and Customization