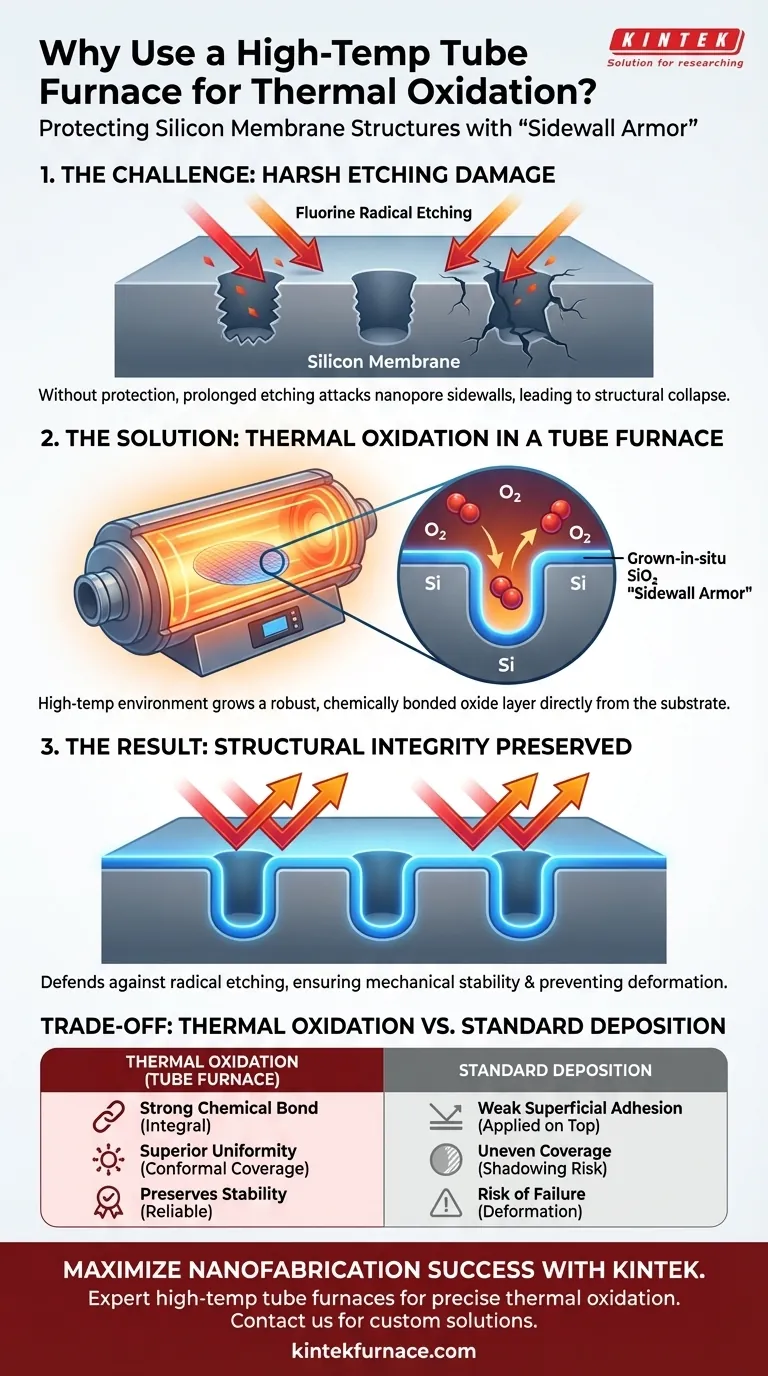

The primary utility of a high-temperature tube furnace is structural preservation: it is used to grow a uniform silicon dioxide passivation layer in situ directly on the internal walls of nanopores. Unlike standard deposition methods, this thermal oxidation process creates a robust oxide layer—often around 25 nanometers thick—that is chemically bonded to the silicon substrate. This layer serves as a critical defensive barrier, ensuring the single-crystal silicon membrane survives subsequent harsh processing steps without deformation.

Core Takeaway: The tube furnace enables the creation of "sidewall armor"—a strongly bonded, highly uniform oxide layer—that protects delicate nanopore structures from damage during prolonged fluorine radical etching, thereby preserving the mechanical integrity of the silicon membrane.

Creating the Protective Barrier

Superior Bonding and Uniformity

The high-temperature environment of the tube furnace allows for thermal oxidation, a process distinct from simple coating methods.

During this process, oxygen reacts with the silicon substrate to grow a silicon dioxide layer in situ. This results in an oxide layer that possesses high thickness uniformity and is strongly bonded to the underlying silicon.

The "Sidewall Armor" Concept

The primary reference explicitly describes this oxide layer as "armor" for the nanopore sidewalls.

Because the oxidation occurs within the furnace, it effectively coats the internal geometry of the nanopores. This creates a continuous, protective shell that conforms perfectly to the complex structures of the membrane.

Ensuring Structural Integrity

Defending Against Radical Etching

The formation of buried cavities typically requires prolonged isotropic fluorine radical etching.

Without protection, this aggressive etchant would attack the sidewalls of the nanopores, altering their shape or destroying them entirely. The thermally grown oxide layer is resistant to this specific chemistry, effectively shielding the silicon sidewalls from the etchant.

Preventing Mechanical Failure

The ultimate goal of this treatment is to maintain the mechanical stability of the single-crystal silicon membrane.

If the sidewalls were exposed or weakly protected during cavity formation, the membrane could suffer from deformation or structural collapse. The tube furnace treatment ensures the membrane remains rigid and intact throughout the fabrication process.

Understanding the Process Trade-offs

Thermal Oxidation vs. Standard Deposition

The primary trade-off highlighted is the distinction between thermal oxidation and standard deposition processes.

Standard deposition often applies a material on top of a surface, which may suffer from poor adhesion or uneven coverage inside deep pores. In contrast, the tube furnace consumes a small amount of the silicon surface to grow the oxide, resulting in a bond that is integral to the material rather than superficial.

The Necessity of Precision

While standard deposition might be faster or operate at lower temperatures, it fails to provide the strong bonding required for this application.

For silicon membrane structures, the risk of sidewall deformation outweighs the convenience of standard deposition, making the high-temperature tube furnace the necessary choice for reliability.

Making the Right Choice for Your Goal

To ensure the success of your silicon membrane fabrication, consider the following regarding the oxidation step:

- If your primary focus is mechanical stability: Utilize the high-temperature tube furnace to grow an oxide layer that prevents deformation during aggressive etching cycles.

- If your primary focus is geometric precision: Rely on thermal oxidation to ensure high thickness uniformity inside the internal walls of the nanopores, rather than risking the uneven coverage of standard deposition.

The high-temperature tube furnace is not just a heating element; it is a precision tool for chemically engineering the durability of your device at the nanoscale.

Summary Table:

| Feature | Thermal Oxidation (Tube Furnace) | Standard Deposition Methods |

|---|---|---|

| Bonding Type | Chemical bond (grown in situ) | Superficial adhesion (applied on top) |

| Uniformity | Superior thickness uniformity in pores | Potential for uneven coverage/shadowing |

| Etch Resistance | High (acts as 'sidewall armor') | Variable (may delaminate) |

| Structural Impact | Preserves mechanical stability | Risk of deformation or collapse |

| Substrate Interaction | Consumes silicon surface to form oxide | Adds material to the surface |

Maximize Your Nanofabrication Success with KINTEK

Don't risk structural collapse in your delicate silicon membrane projects. KINTEK’s high-temperature tube furnaces provide the thermal precision and uniformity required for robust thermal oxidation, ensuring your nanopores are protected by superior 'sidewall armor.'

Backed by expert R&D and manufacturing, KINTEK offers customizable Tube, Muffle, Rotary, Vacuum, and CVD systems tailored for advanced lab high-temp needs.

Ready to enhance your lab's thermal processing? Contact KINTEK today for a custom furnace solution!

Visual Guide

References

- Sanjeev Vishal Kota, Henri Jansen. Nano-Perforated Silicon Membrane with Monolithically Integrated Buried Cavity. DOI: 10.3390/mi16010104

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What recent advancements have enhanced the performance of lab tubular furnaces? Achieve Unprecedented Precision & Control

- What is the function of a high-temperature tube furnace? Master Grain Growth for Microcrystalline Alloy Samples

- What is a vertical furnace? A Guide to High-Purity, Uniform Thermal Processing

- What is a split tube furnace? Unlock Easy Access for Complex Lab Experiments

- What are the advantages of using a tube furnace? Achieve Precise Thermal Control for Your Lab

- Why is a high-purity argon supply system and a flow meter integrated into a tube furnace? Optimize Pyrolysis Quality

- How are vacuum tube furnaces utilized in the metallurgical industry? Enhance Metal Purity and Performance

- What is the high temperature of a tube furnace? Understanding the 1700°C Limit and Key Components