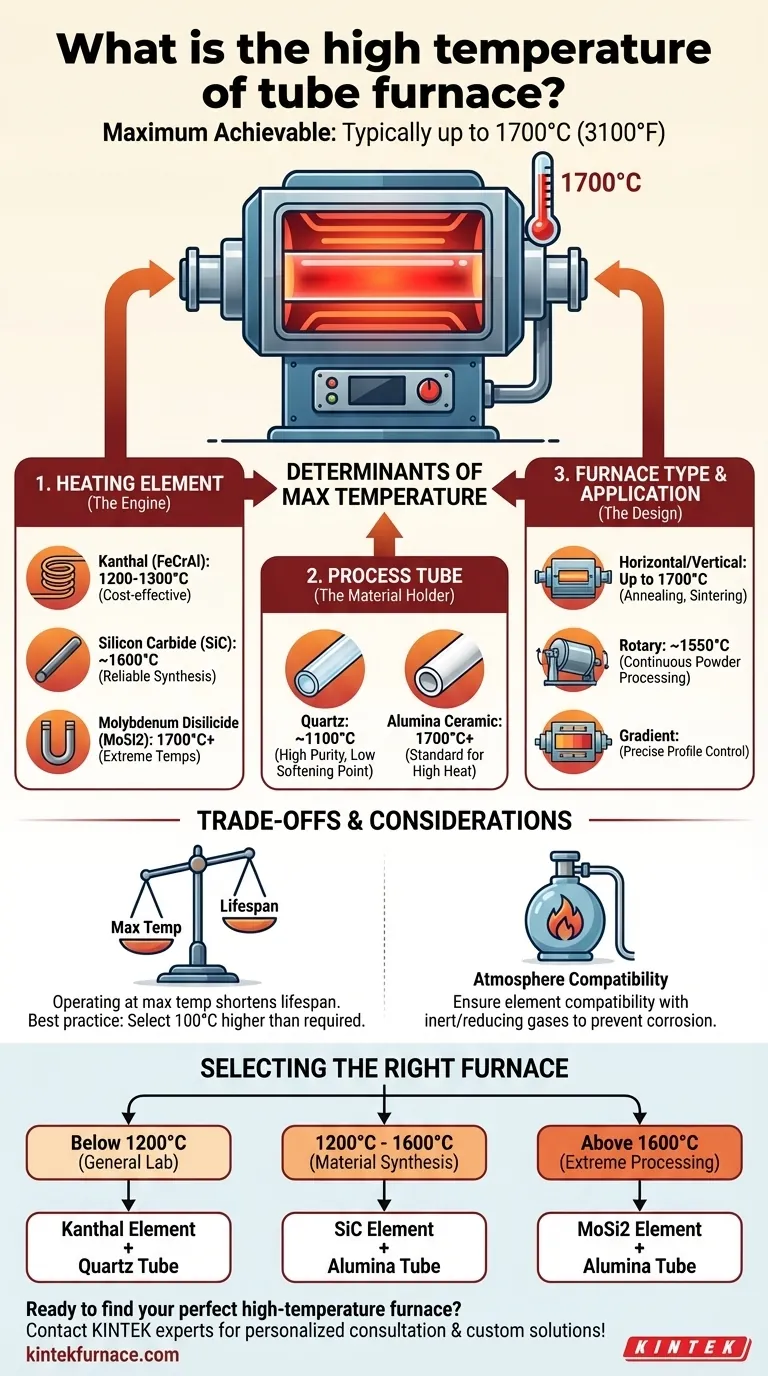

For a high-temperature tube furnace, the maximum achievable temperature is typically 1700°C (3100°F). However, this figure is not universal, as the specific limit depends heavily on the furnace's design, heating elements, and the material of the process tube itself. Other models are commonly rated for maximums of 1550°C or 1600°C based on their intended application.

A furnace's maximum temperature is not just a single specification; it is a result of an engineered system. The true question is not "how hot can it get," but "which components are enabling that temperature, and are they right for my process?"

What Determines a Tube Furnace's Maximum Temperature?

The final temperature rating of a tube furnace is a balance between three critical components: the heating elements, the process tube, and the overall construction.

The Role of the Heating Element

The engine of the furnace is its heating element, and different materials have different thermal limits.

- Kanthal (FeCrAl) elements are common and cost-effective, but typically max out around 1200-1300°C.

- Silicon Carbide (SiC) elements are a step up, reliably reaching temperatures up to 1600°C, making them suitable for many high-temperature synthesis applications.

- Molybdenum Disilicide (MoSi2) elements are used for the highest temperature ranges, capable of operating continuously at 1700°C and even reaching 1800°C in some designs.

The Importance of the Process Tube

The material being heated is placed inside a tube that must withstand the extreme temperatures and desired atmosphere.

- Quartz tubes are excellent for purity and creating a vacuum but have a relatively low softening point, limiting their use to around 1100°C.

- Alumina ceramic tubes are the standard for high-temperature work. High-purity alumina can withstand temperatures of 1700°C or more, making it the default choice for furnaces with SiC or MoSi2 elements.

Furnace Type and Application

The furnace's physical design is tailored for specific processes, which also influences its temperature range.

As noted in standard specifications, a horizontal or vertical tube furnace is often designed for maximum heat, reaching 1600°C to 1700°C for processes like annealing or sintering.

In contrast, a rotary tube furnace, designed for continuous processing and mixing of powders, may have a slightly lower maximum temperature (e.g., 1550°C) due to its mechanical complexity.

A gradient tube furnace, which creates a precise temperature profile along its length, is also built for a specific purpose that may prioritize control over absolute maximum heat.

Understanding the Trade-offs and Limitations

Selecting a furnace based on its maximum temperature alone can lead to operational challenges and premature failure.

Temperature vs. Lifespan

Operating any furnace at its absolute maximum rated temperature for extended periods will dramatically shorten the lifespan of the heating elements and the process tube. For longevity, it is best practice to select a furnace with a maximum temperature at least 100°C higher than your required operating temperature.

Atmosphere Compatibility

The type of gas used inside the tube (e.g., inert argon, reducing hydrogen) can react with the heating elements at high temperatures. You must ensure that your chosen heating elements are compatible with your process atmosphere to prevent corrosion and failure. This is why many furnaces are specified for inert or reducing atmospheres.

Differentiating from Other Furnace Types

It is crucial not to confuse a ceramic tube furnace with other ultra-high-temperature equipment. For example, some vacuum furnaces using graphite elements can reach 2600°C or higher, but these are entirely different systems designed for carbon-based, oxygen-free environments and do not use ceramic tubes.

Selecting the Right Furnace for Your Application

Your choice should be dictated by your specific material processing requirements, not a quest for the highest possible number.

- If your primary focus is general lab heating or processing below 1200°C: A standard furnace with Kanthal elements and a quartz tube is often the most cost-effective and practical choice.

- If your primary focus is high-temperature material synthesis (1200°C - 1600°C): You will need a furnace equipped with Silicon Carbide (SiC) elements and a high-purity alumina process tube.

- If your primary focus is extreme temperature processing (above 1600°C): A furnace with Molybdenum Disilicide (MoSi2) elements is required, representing the upper limit for conventional ceramic tube furnaces.

Ultimately, understanding the components that dictate thermal limits is the key to selecting a furnace that reliably meets your scientific or industrial goals.

Summary Table:

| Component | Common Types | Typical Max Temperature | Key Consideration |

|---|---|---|---|

| Heating Element | Kanthal (FeCrAl) | 1200-1300°C | Cost-effective for lower temps |

| Silicon Carbide (SiC) | Up to 1600°C | Reliable for synthesis | |

| Molybdenum Disilicide (MoSi2) | Up to 1700°C+ | For extreme temperatures | |

| Process Tube | Quartz | ~1100°C | Excellent purity, softens at high heat |

| Alumina Ceramic | 1700°C+ | Standard for high-temperature work | |

| Furnace Type | Horizontal/Vertical | Up to 1700°C | For annealing, sintering |

| Rotary | ~1550°C | For continuous powder processing |

Ready to find the perfect high-temperature furnace for your specific process?

Your application's success depends on matching the furnace's components—heating elements, process tube, and design—to your exact temperature and atmosphere requirements.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, and Vacuum & Atmosphere Furnaces, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

We can help you select or custom-build a system that ensures reliability, longevity, and optimal performance for your research or production goals.

Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety