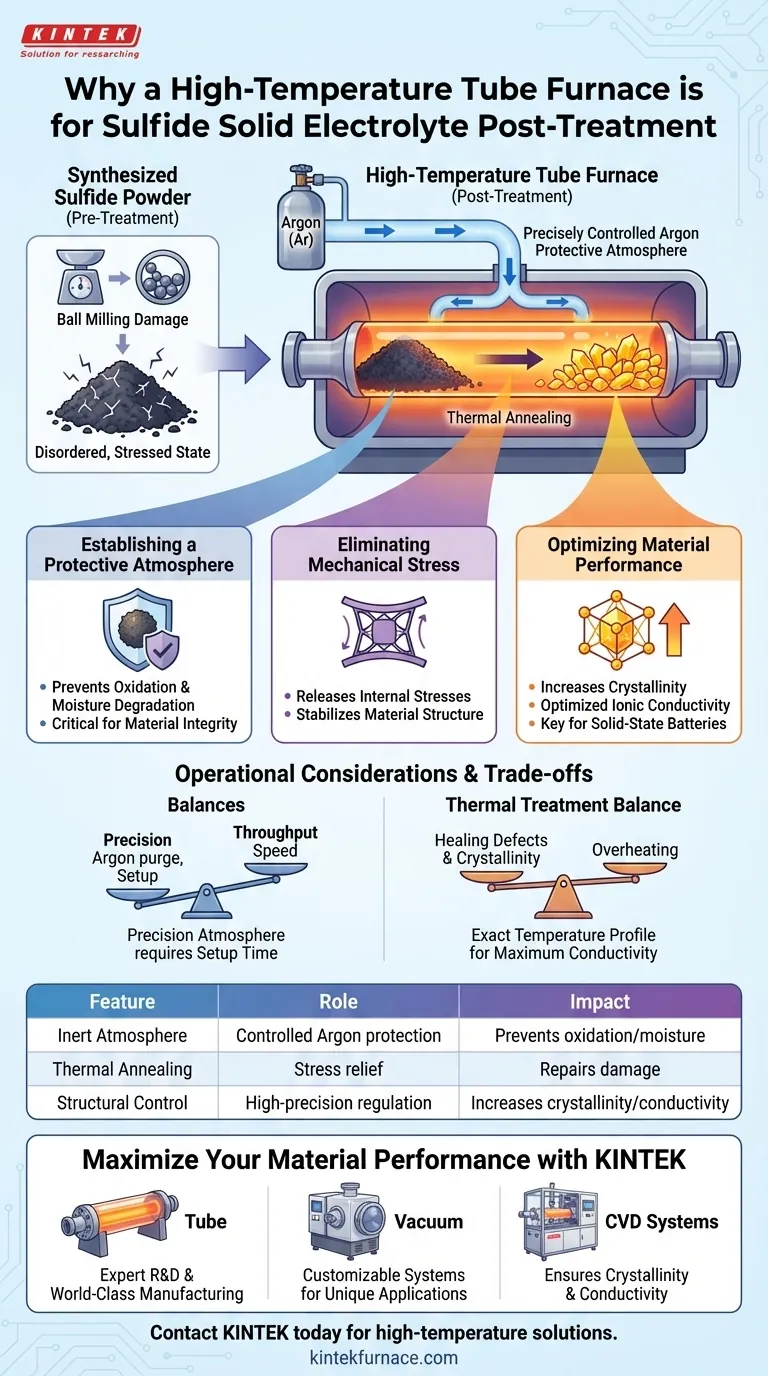

A high-temperature tube furnace is required to create a precisely controlled argon protective atmosphere for annealing sulfide solid electrolyte powders. This specific thermal treatment is critical for repairing the mechanical damage caused by ball milling and transforming the raw powder into a high-performance material.

The furnace serves as a controlled reaction vessel that eliminates internal stresses within the material. This process is the key to shifting from a disordered, stressed state to a highly crystalline structure with optimized ionic conductivity.

The Critical Functions of the Tube Furnace

Establishing a Protective Atmosphere

Sulfide solid electrolytes are highly sensitive materials. The primary function of the tube furnace is to maintain a precisely controlled argon protective atmosphere.

This inert environment is non-negotiable during the heating process. It prevents the material from reacting with oxygen or moisture in the air, which would degrade the electrolyte before it forms the correct structure.

Eliminating Mechanical Stress

The synthesis of these electrolytes typically begins with high-energy ball milling. While effective for mixing, this mechanical process generates significant internal stresses within the powder particles.

The tube furnace provides the thermal energy necessary to relax the material structure. By annealing the powder, you effectively release these pent-up stresses, stabilizing the material for practical application.

Optimizing Material Performance

The ultimate goal of using the furnace is to enhance the physical properties of the electrolyte. The heat treatment directly increases the crystallinity of the solid electrolyte.

There is a direct correlation between this structural order and performance. Higher crystallinity achieved through proper annealing leads to optimized ionic conductivity, which is the most critical metric for a solid-state battery electrolyte.

Operational Considerations and Trade-offs

Precision vs. Throughput

The requirement for a "precisely controlled" atmosphere implies a trade-off in processing speed. You cannot simply heat these materials in an open-air oven; the setup time for purging and sealing the tube with argon is mandatory.

Rushing the atmosphere preparation to save time will compromise the protective environment, leading to material degradation regardless of the temperature used.

The Balance of Thermal Treatment

While heat is necessary to fix mechanical defects, the temperature profile must be exact.

The goal is to provide enough energy to increase crystallinity and heal defects without overheating the sample. The tube furnace allows for this specific regulation, ensuring the material reaches the sweet spot for maximum conductivity.

Making the Right Choice for Your Goal

To get the most out of your synthesis process, align your furnace usage with your specific objectives:

- If your primary focus is maximizing ionic conductivity: Prioritize the annealing phase to ensure you achieve the highest possible degree of crystallinity.

- If your primary focus is material stability: Focus on the integrity of the argon atmosphere within the tube to prevent any oxidation during the stress-relief process.

The high-temperature tube furnace is not just a heating element; it is a specialized tool for structural repair and atmospheric protection.

Summary Table:

| Feature | Role in Post-Treatment | Impact on Electrolyte |

|---|---|---|

| Inert Atmosphere | Controlled Argon protection | Prevents oxidation and moisture degradation |

| Thermal Annealing | Stress relief from ball milling | Repairs mechanical damage and internal stress |

| Structural Control | High-precision temperature regulation | Increases crystallinity for optimized ionic conductivity |

Maximize Your Material Performance with KINTEK

Unlock the full potential of your sulfide solid electrolytes with KINTEK's specialized high-temperature solutions. Backed by expert R&D and world-class manufacturing, we provide high-precision Tube, Vacuum, and CVD systems designed to maintain the rigorous atmosphere control your research demands. Whether you need a standard setup or a customizable system for unique battery applications, our furnaces ensure the crystallinity and conductivity your projects require.

Contact KINTEK today to discuss your lab’s high-temperature needs

Visual Guide

References

- Gordon Jarrold, Arumugam Manthiram. Delineating the Intricate Impact of Carbon in All‐solid‐state Lithium‐Sulfur Batteries. DOI: 10.1002/aenm.202502557

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a tube sintering furnace play in the calcination of Lithium Iron Phosphate? Optimizing LFP Performance

- What is the function of a tube reduction furnace? Enhance Ru@PG Catalysts with Ar/H2 Precision

- What specific environmental conditions does a horizontal quartz tube furnace provide during boron diffusion? - KINTEK

- What is the function of a phosphorus diffusion tube furnace? Creating MoS2/Si Heterojunctions with Precision

- What is sintering, and how is it performed in horizontal furnaces? Unlock Precision in Powder Processing

- What role does a high-temperature tube furnace play in the conversion of precursors into NPC@MoS2?

- What role do sealed quartz or glass tubes play in the synthesis of ternary copper sulfides? Mastering Micro-Reactors

- Why are a high-temperature tube furnace and its reduction atmosphere control system core equipment for SrVO3?