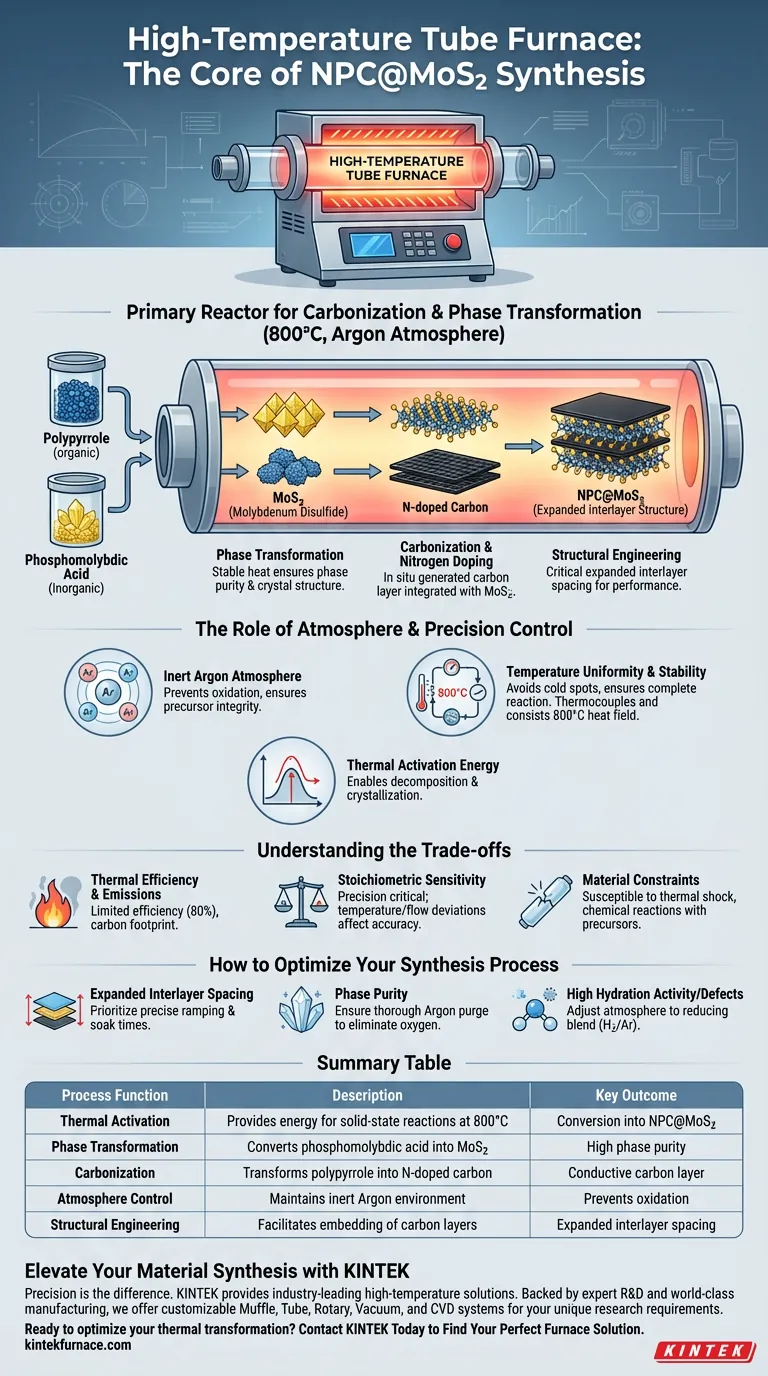

In the synthesis of NPC@MoS2, a high-temperature tube furnace acts as the primary reactor for simultaneous carbonization and phase transformation. It provides a strictly controlled thermal environment—typically maintained at 800°C under an inert argon atmosphere—that enables the chemical conversion of organic and inorganic precursors into a structured nanocomposite.

The tube furnace provides the thermal activation energy required to convert polypyrrole and phosphomolybdic acid into a nitrogen-doped carbon-embedded molybdenum disulfide (NPC@MoS2) structure while preventing oxidation.

The Mechanism of Thermal Transformation

The tube furnace is not merely a heater; it is a precision tool that drives specific chemical reactions through controlled energy input.

Facilitating Phase Transformation

The furnace provides the high-temperature environment necessary to transform phosphomolybdic acid into molybdenum disulfide (MoS2). This process requires stable heat to ensure the precursor reaches the correct phase purity and crystal structure.

Driving Carbonization and Nitrogen Doping

As the MoS2 forms, the furnace simultaneously facilitates the carbonization of polypyrrole. This results in an in situ generated carbon layer that becomes integrated within the MoS2 layers.

Engineering Interlayer Expansion

The controlled heating environment allows the carbon layer to embed within the MoS2 layers. This specific spatial arrangement creates an expanded interlayer structure, which is critical for the electrochemical performance of the final material.

The Role of Atmosphere and Precision Control

Beyond simple heating, the tube furnace manages the chemical environment to ensure the integrity of the NPC@MoS2 composite.

Maintaining Inert Environments

By using an argon atmosphere, the furnace prevents the oxidation of the precursors. Without this inert protection, the carbon would burn away and the molybdenum would form oxides rather than the desired disulfide.

Temperature Uniformity and Stability

High-temperature tube furnaces utilize thermocouples and feedback control systems to maintain a stable "heat field." This uniformity is essential for ensuring that the entire sample undergoes a complete and consistent reaction, avoiding "cold spots" that result in impure phases.

Providing Activation Energy

In solid-state synthesis, the furnace provides the thermal activation energy required for reactants to overcome energy barriers. This allows for the decomposition of precursors and the subsequent crystallization of the target NPC@MoS2 product.

Understanding the Trade-offs

While high-temperature tube furnaces are indispensable, they present specific challenges that researchers must manage.

Thermal Efficiency and Emissions

Traditional high-temperature furnaces can have limited thermal efficiency, often around 80%. Additionally, if the furnace is powered by fossil-fuel-generated electricity or combustion, it contributes to the overall carbon footprint of the material production.

Stoichiometric Sensitivity

The precision of the furnace is a double-edged sword; minor fluctuations in temperature or gas flow rates can lead to deviations in the stoichiometric accuracy of the MoS2. If the temperature is too low, carbonization may be incomplete; if too high, the crystal structure may collapse or over-sinter.

Material Constraints

The tubes, often made of quartz or ceramic, are susceptible to thermal shock if cooled too rapidly. Furthermore, certain chemical precursors can react with the tube wall itself at high temperatures, potentially contaminating the sample or damaging the equipment.

How to Optimize Your Synthesis Process

To successfully convert precursors into high-quality NPC@MoS2, your approach to furnace management should depend on your specific material goals.

- If your primary focus is expanded interlayer spacing: Prioritize precise temperature ramping and soak times to allow the in situ carbon to embed evenly between MoS2 layers.

- If your primary focus is phase purity: Ensure the furnace is purged thoroughly with argon before heating to eliminate all traces of oxygen that could lead to molybdenum oxide formation.

- If your primary focus is high hydration activity or defects: Adjust the atmosphere to a reducing blend (such as H2/Ar) if you intend to induce oxygen vacancies or specific metallic states within the precursor.

By precisely tuning the thermal and atmospheric environment, the tube furnace transforms raw precursors into a sophisticated, functional NPC@MoS2 nanocomposite.

Summary Table:

| Process Function | Description | Key Outcome |

|---|---|---|

| Thermal Activation | Provides energy for solid-state reactions at 800°C | Conversion of precursors into NPC@MoS2 |

| Phase Transformation | Converts phosphomolybdic acid into MoS2 | High phase purity and crystal structure |

| Carbonization | Transforms polypyrrole into N-doped carbon | In situ generated conductive carbon layer |

| Atmosphere Control | Maintains inert Argon environment | Prevents oxidation and ensures material integrity |

| Structural Engineering | Facilitates embedding of carbon layers | Expanded interlayer spacing for performance |

Elevate Your Material Synthesis with KINTEK

Precision is the difference between a failed experiment and a breakthrough in nanocomposite synthesis. KINTEK provides industry-leading high-temperature solutions designed for the rigorous demands of NPC@MoS2 production.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need specialized atmosphere control or custom-engineered thermal fields, our lab furnaces are fully customizable to meet your unique research requirements.

Ready to optimize your thermal transformation?

Contact KINTEK Today to Find Your Perfect Furnace Solution

Visual Guide

References

- Hanqing Pan, Lei Zhang. Hollow Carbon and MXene Dual‐Reinforced MoS<sub>2</sub> with Enlarged Interlayers for High‐Rate and High‐Capacity Sodium Storage Systems. DOI: 10.1002/advs.202400364

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What critical function does a high-temperature tube furnace perform for FCNCuM@CNT? Achieve FCC Phase Precision

- What are some common applications of horizontal electric furnaces? Unlock Precision in Thermal Processing

- What is the necessity of annealing treatment for CuCo2O4@rGO? Optimize High-Crystallinity Synthesis in Tube Furnaces

- Why is a high-temperature tube furnace required for LK-99 sintering? Achieve Precise Superconductor Phase Transformation

- What is the difference between a tube furnace and a muffle furnace? Choose the Right High-Temp Solution

- Why is a tube furnace required during the synthesis of phosphorus-doped nickel catalysts using high-purity nitrogen?

- What role does a laboratory tube furnace play in geological and mineralogical research? Unlock Earth's Secrets with Precision

- Why must a programmable vacuum tube furnace with a nitrogen atmosphere be used for Bi2Se3? Optimize Your Thin Films