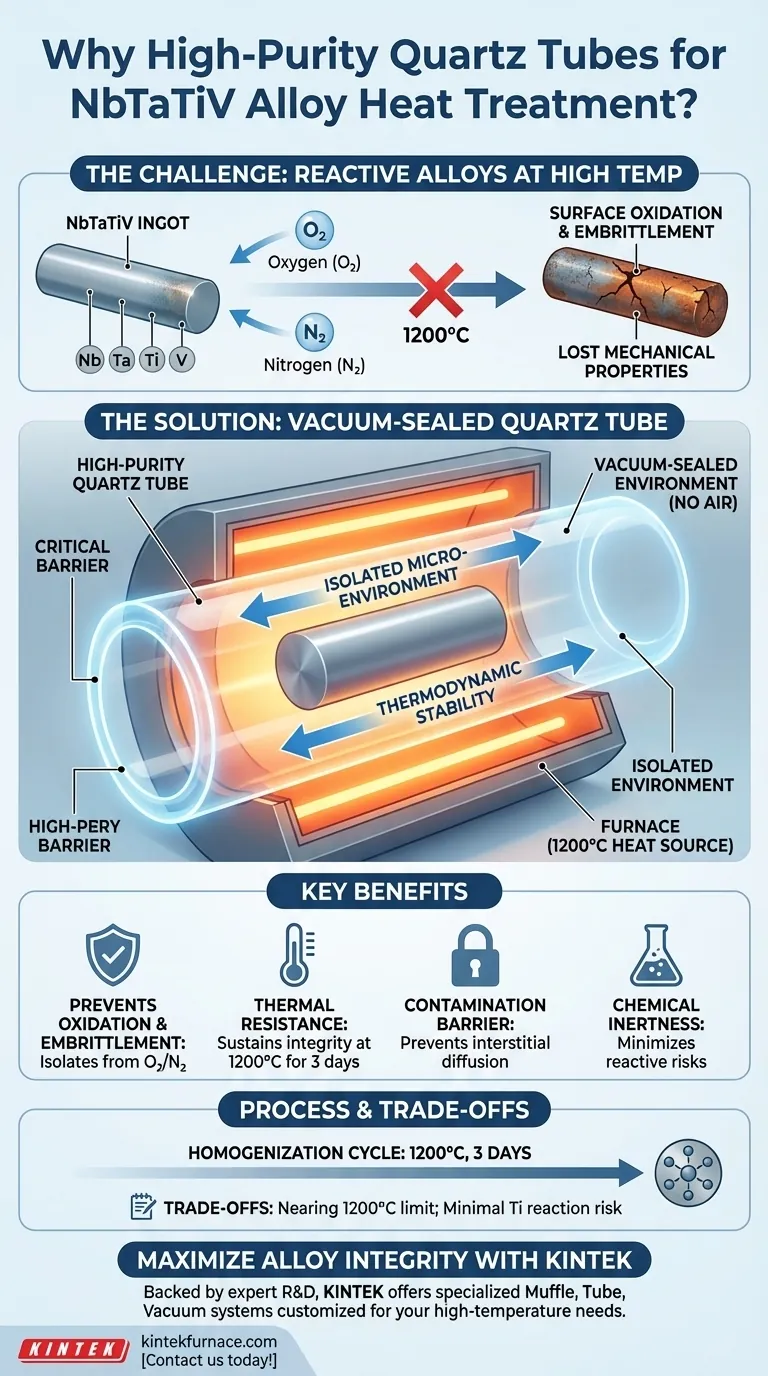

High-purity quartz tubes are the critical barrier required to isolate NbTaTiV alloys from atmospheric contamination during high-temperature processing. Specifically, they facilitate a vacuum-sealed environment that prevents reactive elements within the alloy from bonding with oxygen and nitrogen, which causes surface oxidation and severe embrittlement during prolonged heat treatments at 1200°C.

The use of a vacuum-sealed quartz tube creates a strict, isolated micro-environment that allows the alloy to achieve thermodynamic stability and microstructural homogenization without suffering from environmental degradation or compositional loss.

Protecting Material Integrity at Extreme Temperatures

Preventing Oxidation and Embrittlement

NbTaTiV alloys are composed of refractory metals that are highly reactive to interstitial elements like oxygen and nitrogen.

If exposed to air at high temperatures, these elements diffuse into the alloy lattice.

This reaction leads to surface oxidation and internal embrittlement, which destroys the mechanical properties of the material.

Ensuring a Strict Protective Atmosphere

The primary function of the quartz tube is to maintain a vacuum around the ingot.

This isolation acts as a physical and chemical shield against atmospheric impurities.

By removing the air source, the tube ensures that the material remains pure throughout the heating cycle.

Facilitating Long-Term Homogenization

Withstanding Prolonged Heat Cycles

The homogenization annealing process for NbTaTiV alloys is rigorous, often requiring treatment at 1200°C for a duration of 3 days.

The containment vessel must maintain its structural integrity and hermetic seal for this entire period.

High-purity quartz provides the necessary thermal resistance to withstand these sustained temperatures without failing.

Achieving Thermodynamic Stability

The goal of this heat treatment is to allow the alloy's elements to diffuse evenly and reach a thermodynamically stable state.

Any breach in the environment would introduce variables that disrupt this equilibrium.

The sealed tube ensures that the only changes occurring are the intended microstructural adjustments within the alloy itself.

Understanding the Trade-offs

Thermal Limits of Quartz

While high-purity quartz is excellent for treatments up to 1200°C, it is nearing its upper thermal limit.

At temperatures significantly higher than this, quartz may begin to soften or devitrify (crystallize), potentially compromising the vacuum seal.

Reactivity Risks with Active Metals

Although quartz is generally chemically inert, certain highly active elements (like Titanium) can react with silica under extreme conditions if in direct contact.

However, in the context of vacuum sealing, the quartz primarily serves as the vessel to hold the vacuum, minimizing direct reaction risks compared to open-air exposure.

Making the Right Choice for Your Goal

When designing heat treatment protocols for refractory or high-entropy alloys, the containment method determines the quality of the final sample.

- If your primary focus is mechanical ductility: You must use vacuum sealing to prevent the uptake of oxygen and nitrogen, which are the primary causes of brittleness.

- If your primary focus is microstructural uniformity: Rely on the quartz tube to maintain a stable environment for the full 3-day duration, ensuring complete homogenization without surface degradation.

The high-purity quartz tube is not just a container; it is an active component of the process control that guarantees the fidelity of the alloy's composition.

Summary Table:

| Feature | Benefit for NbTaTiV Alloy Heat Treatment |

|---|---|

| Vacuum Sealing | Isolates alloy from oxygen/nitrogen to prevent surface oxidation |

| Thermal Resistance | Sustains structural integrity during 1200°C homogenization cycles |

| Contamination Barrier | Prevents interstitial element diffusion and material embrittlement |

| Chemical Inertness | Minimizes reactive risks for high-purity refractory metal processing |

Maximize Your Alloy Integrity with KINTEK

Don’t let atmospheric contamination compromise your research or production. Backed by expert R&D and manufacturing, KINTEK offers specialized Muffle, Tube, Rotary, Vacuum, and CVD systems—all of which can be customized to your unique high-temperature processing needs. Whether you are treating NbTaTiV alloys or developing new refractory materials, our high-purity quartz and vacuum solutions ensure your samples achieve perfect thermodynamic stability without the risk of embrittlement.

Ready to elevate your thermal processing? Contact us today to find the perfect furnace for your lab!

Visual Guide

References

- Chan-Ho Lee, Saryu Fensin. Deformation Behaviors in Single BCC‐Phase Refractory Multi‐Principal Element Alloys under Dynamic Conditions. DOI: 10.1002/advs.202508180

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Magnesium Extraction and Purification Condensing Tube Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a high-temperature vacuum furnace play in sintering magnesium composites? Key Success Factors

- How does a precise temperature control system prevent Rubidium Chloride loss? Optimize Vacuum Distillation Yield

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- Why does the surface of steel appear bright after vacuum hardening? Discover the Secret to Flawless Finishes

- How does the sealed shell of a vacuum furnace contribute to its functionality? Unlock High-Purity Thermal Processing

- How does vacuum brazing differ from welding? Precision Joining Without Melting Base Materials

- In which industries are vacuum sintering furnaces commonly used? Essential for High-Performance Materials

- How does an ultra-high vacuum baking furnace facilitate mid-temperature baking for Niobium cavities? | KINTEK