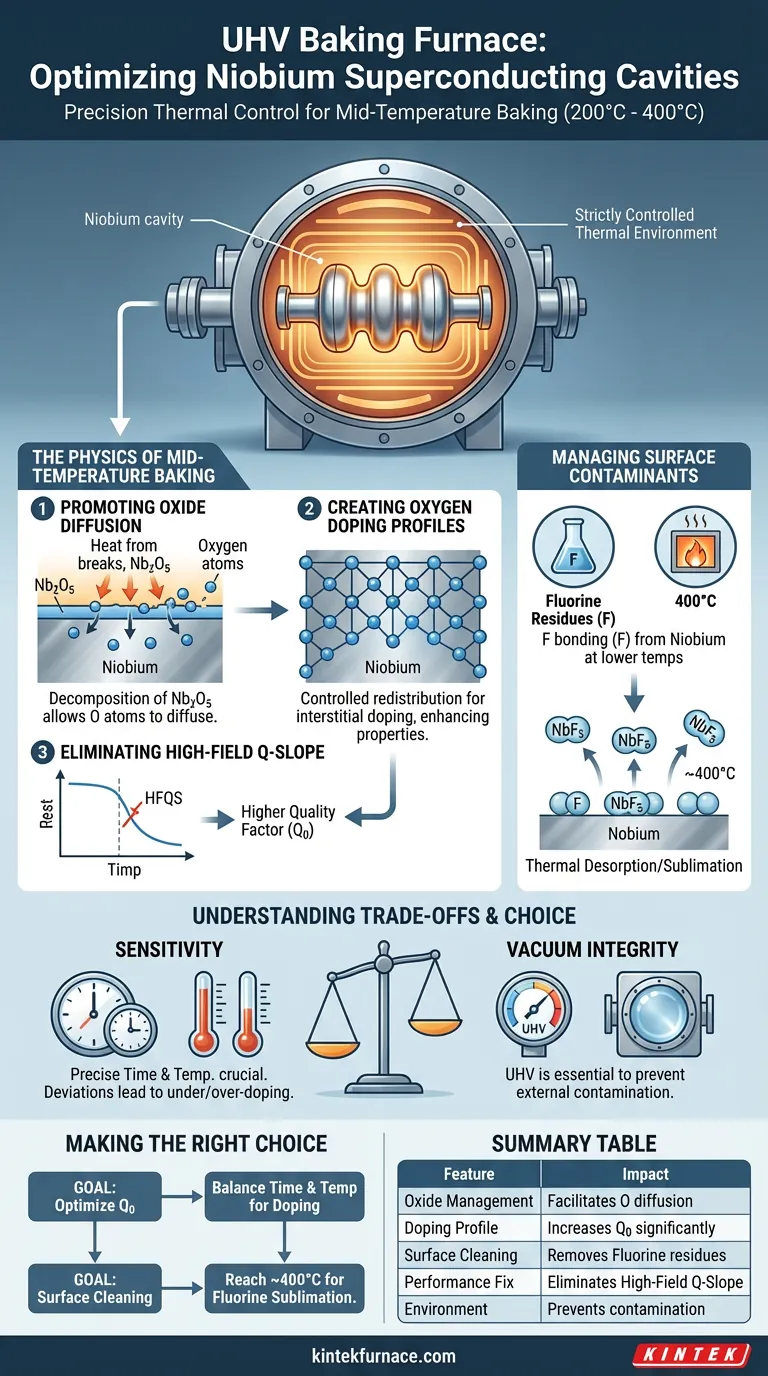

An ultra-high vacuum (UHV) baking furnace facilitates mid-temperature baking by creating a strictly controlled thermal environment between 200°C and 400°C. This specific range triggers the thermal decomposition of natural surface oxides (specifically Nb2O5), allowing oxygen atoms to diffuse into the Niobium bulk matrix to improve superconducting performance.

Core Takeaway The furnace functions not merely as a heating element, but as a precision tool for atomic redistribution. By balancing vacuum pressure and temperature, it converts surface oxide layers into a beneficial interstitial oxygen doping profile, significantly enhancing the cavity's quality factor (Q0).

The Physics of Mid-Temperature Baking

To understand the value of the UHV furnace, one must look beyond simple heating. The equipment enables specific material science mechanisms that define cavity performance.

Promoting Oxide Diffusion

The primary function of the furnace in this temperature range is to manage the natural oxide layer, niobium pentoxide (Nb2O5).

Under ultra-high vacuum conditions, the furnace induces the thermal decomposition of this oxide layer.

Rather than stripping the oxygen away entirely, the environment allows the oxygen atoms to diffuse from the surface into the Niobium matrix.

Creating Oxygen Doping Profiles

This diffusion process is not random; it is a controlled method of doping.

By maintaining precise temperature stability, the furnace facilitates the redistribution of oxygen atoms.

This results in specific oxygen doping profiles within the material, which are essential for optimizing the superconducting properties of the cavity.

Eliminating High-Field Q-Slope

A critical outcome of this diffusion process is the mitigation of performance losses.

The redistribution of oxygen helps eliminate the high-field Q-slope (HFQS), a common phenomenon where cavity performance degrades at high accelerating gradients.

This leads to a higher overall quality factor (Q0).

Managing Surface Contaminants

Beyond oxygen management, the furnace plays a crucial role in regulating chemical residues left over from manufacturing processes.

Addressing Fluorine Residues

Cavities often undergo chemical polishing using hydrofluoric acid, leaving Fluorine (F) residues on the surface.

The baking process in a UHV furnace is the primary method for regulating this content.

Temperature-Dependent Cleaning

The furnace's ability to reach specific temperatures within the mid-range is vital for cleaning efficacy.

At lower temperatures (around 230°C), Fluorine tends to bond with Niobium.

However, at higher temperatures (approaching 400°C), the furnace facilitates the thermal desorption or sublimation of compounds like Niobium fluoride (NbF5), effectively cleaning the surface.

Understanding the Trade-offs

While mid-temperature baking is highly effective, it relies on precise operational parameters.

Sensitivity to Time and Temperature

The diffusion of oxygen is a kinetic process heavily dependent on exact exposure times and temperatures.

Slight deviations in the baking profile can lead to incorrect oxygen diffusion depths.

This can result in under-doping (insufficient Q0 gain) or over-doping (potential degradation of other superconducting parameters).

The Necessity of Vacuum Integrity

The process relies entirely on an ultra-high vacuum (UHV) environment.

Any compromise in vacuum pressure during heating would introduce external contaminants rather than facilitating the controlled diffusion of existing surface oxides.

Making the Right Choice for Your Goal

The specific parameters you select for the furnace run should depend on the primary deficiency of the cavity.

- If your primary focus is Optimizing Q0: Prioritize a baking profile that balances time and temperature to achieve the ideal oxygen diffusion depth for doping.

- If your primary focus is Surface Cleaning: Ensure the furnace reaches the upper end of the mid-temperature range (approx. 400°C) to ensure the sublimation of Fluorine residues.

Ultimately, the UHV furnace allows you to turn a surface defect (oxide layers) into a performance asset (interstitial doping) through precise thermal control.

Summary Table:

| Feature | Mid-Temperature Range (200°C - 400°C) | Impact on Niobium Cavities |

|---|---|---|

| Oxide Management | Decomposition of Nb2O5 | Facilitates oxygen diffusion into the bulk matrix |

| Doping Profile | Controlled interstitial doping | Increases the Quality Factor (Q0) significantly |

| Surface Cleaning | Sublimation of NbF5 at ~400°C | Removes Fluorine residues from chemical polishing |

| Performance Fix | Elimination of High-Field Q-Slope | Prevents performance degradation at high gradients |

| Environment | Ultra-High Vacuum (UHV) | Prevents contamination during thermal redistribution |

Elevate Your Superconducting Research with KINTEK

Precision is the difference between a surface defect and a performance asset. Backed by expert R&D and world-class manufacturing, KINTEK offers specialized Ultra-High Vacuum (UHV), CVD, and high-temperature furnace systems designed to meet the rigorous demands of Niobium cavity processing. Whether you need standard or fully customizable solutions for mid-temperature baking or oxygen doping, our team is ready to deliver the thermal control you require.

Ready to optimize your cavity Quality Factor?

Visual Guide

References

- Alena Prudnikava, Jens Knobloch. <i>In-situ</i> synchrotron x-ray photoelectron spectroscopy study of medium-temperature baking of niobium for SRF application. DOI: 10.1088/1361-6668/ad4825

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are some examples of vacuum brazing projects? Discover High-Strength Joining for Aerospace and Medical

- Why is vacuum brazing particularly suitable for aerospace applications? Achieve Strong, Pure Joints for Critical Components

- What is the purpose of using industrial heating during non-productive vacuum degassing phases? Protect Your Assets

- How do continuous furnaces demonstrate versatility in processing? Unlock Multi-Process Efficiency for High-Volume Manufacturing

- Why is a high-precision vacuum oven necessary for RGO/PI composite films? Ensure Defect-Free Graded Heat Treatment

- What are the steps in the discharge plasma sintering process? Master Fast, High-Density Material Consolidation

- What are common heating elements used in vacuum furnaces? Optimize Your High-Temp Processes

- How does the annealing furnace process work? Master Material Softening and Stress Relief