At its core, the bright, clean surface of steel after vacuum hardening is a direct result of its environment. The process systematically removes the two main culprits of surface discoloration—atmospheric oxygen and contaminants—leaving behind the pure, untarnished metallic surface of the part.

Vacuum hardening is as much a surface finishing process as it is a heat treatment. By eliminating oxygen, it prevents the formation of oxide scale that plagues traditional methods, resulting in a part that is not only hard but also clean and dimensionally precise right out of the furnace.

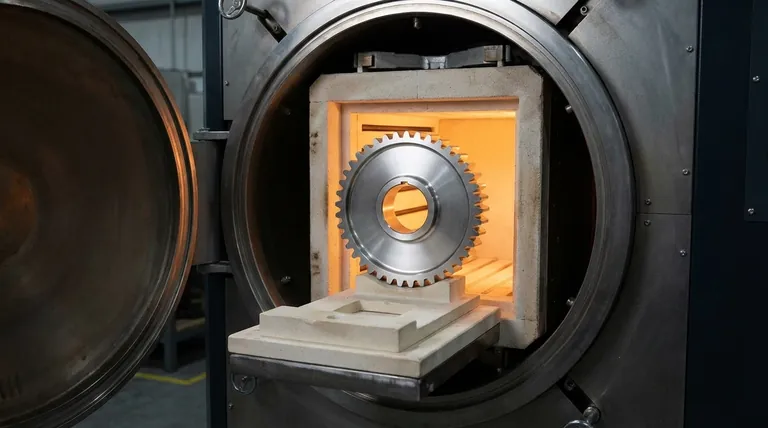

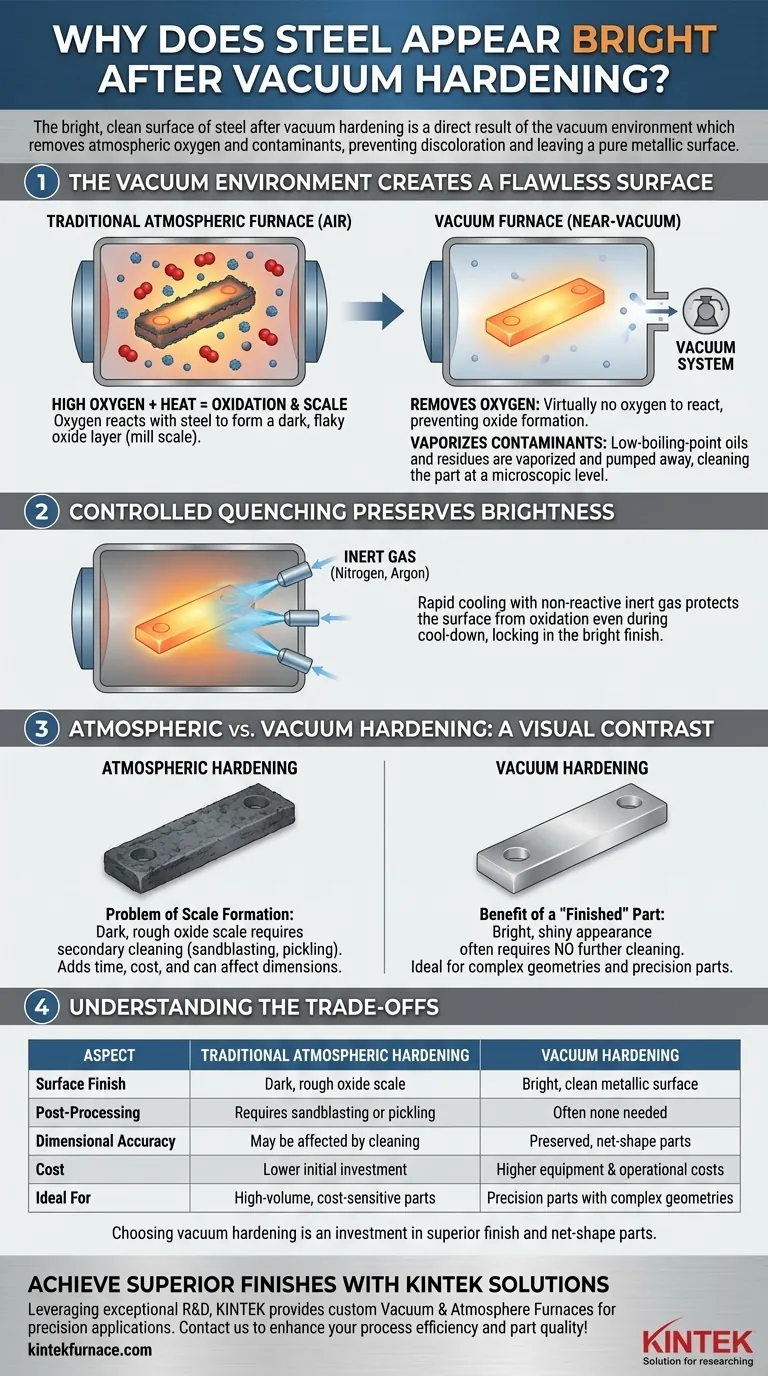

How the Vacuum Creates a Flawless Surface

To understand the bright finish, you must first understand what the vacuum is designed to prevent. Traditional heat treatment occurs in furnaces filled with air, which is rich in oxygen.

The Critical Role of Removing Oxygen

At high temperatures, steel is highly reactive with oxygen. This reaction, called oxidation, forms a dark, flaky layer of iron oxides known as mill scale.

A vacuum furnace works by pumping out the atmosphere before heating begins. By creating a near-vacuum, there is virtually no oxygen left to react with the hot steel surface, completely preventing the formation of this dulling oxide layer.

The Effect of Heat on Surface Contaminants

Nearly all metal parts have residual contaminants on their surface before treatment, such as cutting fluids, oils, or cleaning agents.

During the heating cycle in a vacuum, these low-boiling-point impurities are vaporized or "volatilized." The furnace's vacuum system then pumps these vapors away, effectively cleaning the part at a microscopic level.

The Quenching Process

Even the cooling (quenching) phase is controlled to maintain the bright finish. Instead of being exposed to open air while hot, the steel is rapidly cooled using a high-pressure blast of an inert gas like nitrogen or argon.

Because these gases are non-reactive, the steel's surface remains protected from oxidation even as it cools down from its critical temperature, preserving the brightness achieved during heating.

Atmospheric Hardening vs. Vacuum Hardening: A Visual Contrast

The difference between the two methods is not just functional; it is immediately visible on the finished part.

The Problem of Scale Formation

Parts hardened in an atmospheric furnace emerge with a dark gray or black, rough surface. This scale must be removed through secondary operations like sandblasting, tumbling, or chemical pickling.

These extra steps add time, cost, and can negatively affect the part's final dimensions and surface finish.

The Benefit of a "Finished" Part

A vacuum-hardened part, by contrast, exits the furnace with a bright, often satin or shiny appearance. In many cases, it requires no further surface cleaning.

This is a significant advantage for components with complex geometries or for precision parts like molds and dies, where preserving every detail of the surface is critical.

Understanding the Trade-offs

While vacuum hardening produces superior surface results, it is not the default choice for every application. The decision involves clear trade-offs.

Equipment and Operational Costs

Vacuum furnaces are complex machines that represent a significantly higher capital investment than standard atmospheric furnaces. Their operation and maintenance also demand more specialized knowledge and are generally more expensive.

Cycle Times

Achieving a deep vacuum and executing the controlled heating and gas quenching cycles can sometimes take longer than a comparable atmospheric hardening process, potentially impacting throughput for high-volume production.

Process Limitations

While versatile, vacuum hardening is not a universal solution. Some very low-cost, high-volume parts may not justify the added expense, especially if they undergo subsequent machining that would remove the scaled surface anyway.

Making the Right Choice for Your Goal

Selecting the correct hardening process depends entirely on the requirements of the final component.

- If your primary focus is final surface finish and dimensional accuracy: Vacuum hardening is the clear choice, as it eliminates the need for aggressive post-processing cleaning that can alter the part.

- If your part has intricate details or internal passages: Vacuum hardening ensures these hard-to-reach areas remain clean and free of scale.

- If you are producing simple, high-volume parts where cost is the main driver: Traditional atmospheric hardening may be more economical, provided a scaled surface is acceptable or will be removed later.

Ultimately, choosing vacuum hardening is an investment in achieving a superior finish and net-shape part directly from the heat treatment process.

Summary Table:

| Aspect | Traditional Atmospheric Hardening | Vacuum Hardening |

|---|---|---|

| Surface Finish | Dark, rough oxide scale | Bright, clean metallic surface |

| Post-Processing | Requires sandblasting or pickling | Often none needed |

| Dimensional Accuracy | May be affected by cleaning | Preserved, net-shape parts |

| Cost | Lower initial investment | Higher equipment and operational costs |

| Ideal For | High-volume, cost-sensitive parts | Precision parts with complex geometries |

Achieve superior surface finishes and dimensional precision with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with custom Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures we meet your unique experimental needs. Contact us today to discuss how our vacuum hardening solutions can enhance your process efficiency and part quality!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance