At its core, the sealed shell of a vacuum furnace is the primary component enabling high-purity thermal processing. By creating an entirely airtight enclosure, the shell's fundamental job is to isolate the internal environment from the outside atmosphere. This isolation is the prerequisite for removing contaminants and gaining precise control over the conditions required for advanced material treatment.

The furnace shell should not be seen as a passive container. It is an active system engineered for three critical purposes: achieving isolation from atmospheric contamination, enabling precise control of the internal atmosphere, and maintaining structural integrity under extreme pressure and temperature differentials.

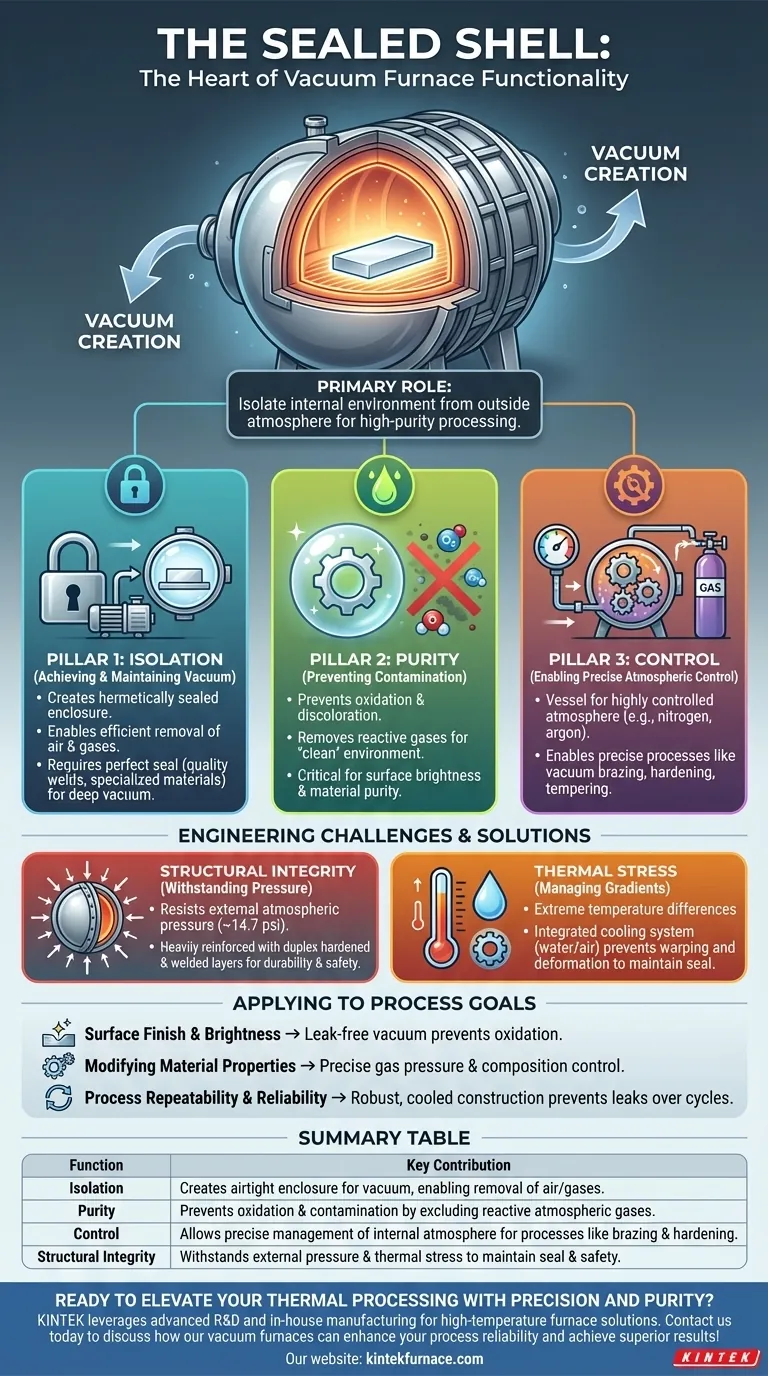

The Pillars of Shell Functionality

To understand the furnace, you must first understand the foundational roles of its shell. Its design directly enables the unique capabilities of vacuum-based thermal processing.

Pillar 1: Achieving and Maintaining Vacuum (Isolation)

The first and most obvious function of the shell is to form a hermetically sealed chamber. This enclosure is typically constructed from welded carbon steel or stainless steel plates.

This airtight integrity allows the vacuum pumping system to efficiently remove air and other gases. Without a perfect seal, achieved through quality welds and specialized vacuum sealing materials on removable parts like doors, a deep vacuum would be impossible to achieve or maintain.

Pillar 2: Preventing Contamination (Purity)

By enabling a vacuum, the shell directly prevents contamination of the workpiece. Atmospheric air contains reactive gases, primarily oxygen, which cause oxidation and discoloration on a material's surface when heated.

Removing these gases creates a "clean" environment. This is critical for processes where surface brightness, finish, and material purity are non-negotiable outcomes.

Pillar 3: Enabling Precise Atmospheric Control (Control)

Once a vacuum is established, the sealed shell becomes the vessel for a new, highly controlled atmosphere. This is where advanced heat treatment becomes possible.

Process engineers can backfill the chamber with specific gases, such as nitrogen or argon, at very precise pressures. The sealed shell contains this engineered atmosphere, allowing for processes like vacuum brazing, hardening, and tempering that modify a material's properties in a predictable and repeatable way.

Understanding the Engineering Challenges

The shell's simple appearance belies significant engineering complexity. It must perform its functions while withstanding immense physical forces.

The Challenge of Structural Integrity

When a high vacuum is pulled, the shell must withstand the full force of external atmospheric pressure—approximately 14.7 pounds per square inch (or 101 kPa) at sea level.

To resist this crushing force without collapsing, shells are heavily reinforced. They are often built with duplex hardened and welded metal layers to ensure long-term durability and operational safety.

Managing Thermal Stress

The shell is subject to extreme temperature gradients. While the interior can reach thousands of degrees, the exterior must remain near ambient temperature.

To manage this, furnace shells are integrated with a cooling system, typically using circulating water or forced air. This cooling is not for the process itself, but to prevent the steel shell from warping or deforming due to thermal expansion. Any deformation could compromise the vacuum seal and lead to process failure.

The Choice of Material

The selection between carbon steel and stainless steel for the shell is a deliberate engineering choice.

Carbon steel is a robust and cost-effective material suitable for most high-vacuum applications. Stainless steel is specified for ultra-high vacuum (UHV) systems or when dealing with corrosive process gases, as it offers superior corrosion resistance and lower outgassing rates.

Applying This to Your Process Goals

Understanding the shell's function helps you evaluate whether a vacuum furnace is the right tool for your specific application and what to look for in a quality machine.

- If your primary focus is surface finish and brightness: The shell's ability to maintain a high, leak-free vacuum to prevent oxidation is its most critical feature.

- If your primary focus is modifying material properties: The shell's function as a sealed vessel for precise gas pressure and composition control is the key enabler for your process.

- If your primary focus is process repeatability and reliability: The robust, cooled, and reinforced construction of the shell is what ensures consistent performance by preventing leaks and deformation over thousands of cycles.

Ultimately, viewing the furnace shell not as a simple box, but as an active environmental control system, is the key to mastering high-performance thermal processing.

Summary Table:

| Function | Key Contribution |

|---|---|

| Isolation | Creates airtight enclosure for vacuum, enabling removal of air and gases |

| Purity | Prevents oxidation and contamination by excluding reactive atmospheric gases |

| Control | Allows precise management of internal atmosphere for processes like brazing and hardening |

| Structural Integrity | Withstands external pressure and thermal stress to maintain seal and safety |

Ready to elevate your thermal processing with precision and purity? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental needs. Contact us today to discuss how our vacuum furnaces can enhance your process reliability and achieve superior results!

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why might a vacuum furnace maintain vacuum during cooling? Protect Workpieces from Oxidation and Control Metallurgy

- How are parts loaded into a vacuum furnace? Ensure Precision and Efficiency in Your Process

- How do vacuum furnaces contribute to long-term cost savings? Reduce Costs with Efficiency and Quality

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures