High-purity argon functions as a critical barrier between your sample and the surrounding oxygen during the carbonization process. Its primary role in a high-temperature tube furnace is to create an inert environment that completely prevents oxidative ablation, ensuring that organic precursors like carbon paper and polyaniline do not burn away at elevated temperatures.

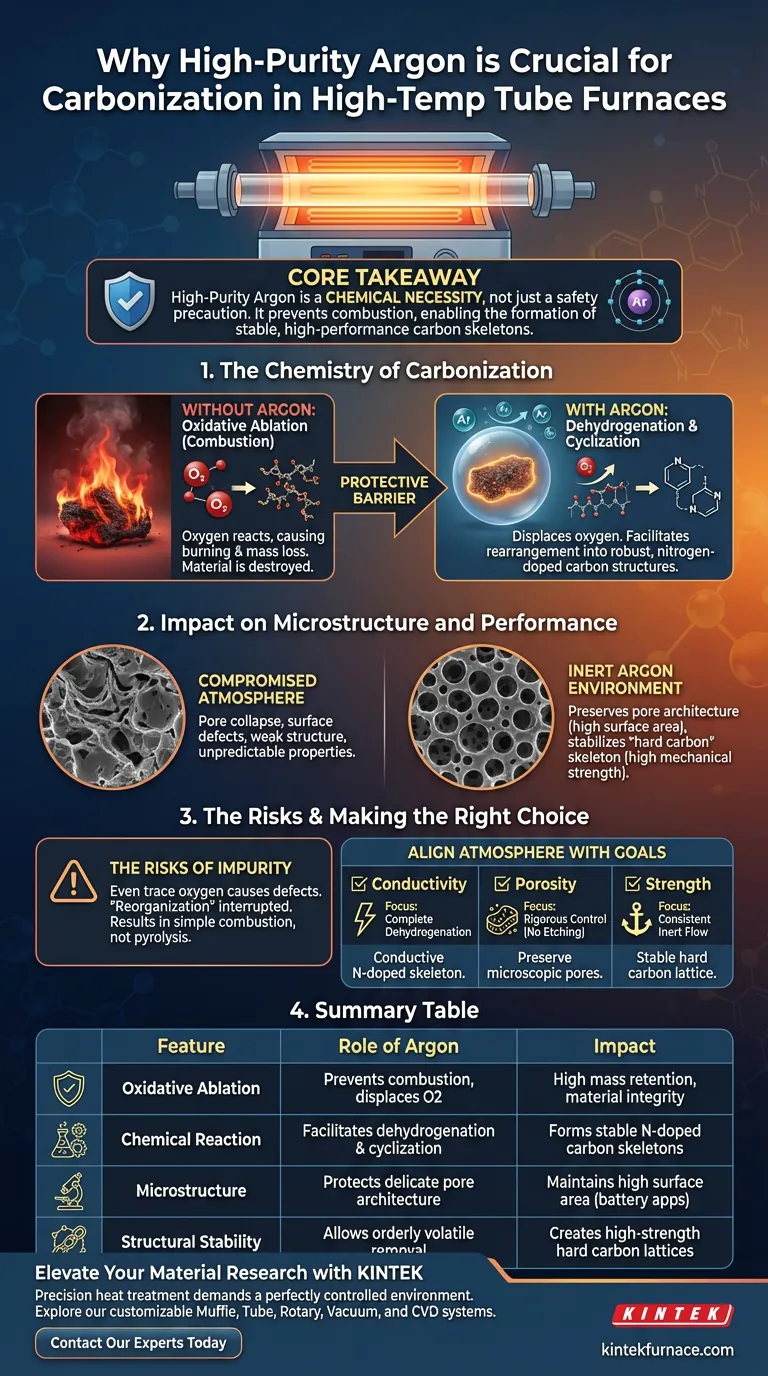

Core Takeaway The introduction of high-purity argon is not merely a safety precaution; it is a chemical necessity for converting organic polymers into stable carbon skeletons. Without this inert atmosphere, the material would undergo combustion rather than the precise dehydrogenation and cyclization reactions required to form high-performance, nitrogen-doped structures.

The Chemistry of Carbonization

Preventing Oxidative Ablation

At the high temperatures required for carbonization, oxygen becomes highly reactive. Without a protective atmosphere, organic components would rapidly react with oxygen, resulting in combustion (burning) and the loss of material mass.

High-purity argon displaces oxygen within the tube, ensuring that the thermal energy is used for structural transformation rather than destruction. This allows the material to survive the heat treatment intact.

Facilitating Dehydrogenation and Cyclization

The goal of carbonization is to rearrange the molecular structure of the precursor. In an inert argon environment, polymers like polyaniline undergo specific chemical changes: dehydrogenation (removal of hydrogen) and cyclization (formation of ring structures).

These reactions are essential for converting the organic components into a robust nitrogen-doped carbon skeleton. Argon ensures these reactions proceed without interference from atmospheric contaminants.

Impact on Microstructure and Performance

Preserving Pore Structure

For applications requiring high surface area, such as battery electrodes, the physical architecture of the material is paramount. The argon atmosphere protects the microscopic pore structure from collapsing or being etched away by oxidation.

By preserving these pores, the process ensures the final material maintains the specific capacity and surface area required for high-performance applications.

Stabilizing the Material Skeleton

The carbonization process removes volatile components to transform polymers into structurally stable materials. The argon atmosphere facilitates this by allowing volatiles to escape without triggering side reactions that could weaken the structure.

This results in a "hard carbon" skeleton with high mechanical strength. This strength is critical if the material is intended to support subsequent active component loading.

The Risks of Atmospheric Compromise

The Cost of Impurity

While the furnace design creates the potential for isolation, the purity of the gas is the deciding factor. Even trace amounts of oxygen entering the chamber can lead to surface defects or partial combustion.

If the atmosphere is not strictly inert, the "reorganization" of the carbon skeleton will be interrupted. This leads to materials with unpredictable electrical properties and reduced structural integrity.

Thermal Treatment vs. Combustion

It is vital to distinguish between burning a material and heat-treating it. A compromised atmosphere turns a sophisticated pyrolysis process into simple combustion.

To achieve the desired rate performance and specific capacity in the final product, the exclusion of oxygen must be absolute.

Making the Right Choice for Your Goal

To maximize the effectiveness of your carbonization process, align your atmospheric control with your specific material objectives:

- If your primary focus is Electrical Conductivity: Ensure the argon purity is sufficient to allow complete dehydrogenation, which establishes the conductive nitrogen-doped carbon skeleton.

- If your primary focus is Structural Porosity: rigorous atmospheric control is required to prevent oxidative etching, which preserves the delicate microscopic pore structure.

- If your primary focus is Mechanical Strength: Maintain a consistent inert flow to allow the orderly removal of volatiles, resulting in a reorganized, stable hard carbon lattice.

Success in carbonization depends less on the heat applied and more on the purity of the environment in which that heat does its work.

Summary Table:

| Feature | Role of High-Purity Argon | Impact on Material Performance |

|---|---|---|

| Oxidative Ablation | Prevents combustion by displacing oxygen | Ensures high mass retention and material integrity |

| Chemical Reaction | Facilitates dehydrogenation & cyclization | Forms stable, nitrogen-doped carbon skeletons |

| Microstructure | Protects delicate pore architecture | Maintains high surface area for battery applications |

| Structural Stability | Allows orderly removal of volatiles | Creates high-strength, durable hard carbon lattices |

| Atmospheric Purity | Eliminates trace surface defects | Ensures predictable electrical and mechanical properties |

Elevate Your Material Research with KINTEK

Don't let atmospheric impurities compromise your carbonization results. At KINTEK, we understand that precision heat treatment requires more than just high temperatures—it demands a perfectly controlled environment.

Backed by expert R&D and manufacturing, KINTEK offers advanced Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your specific gas purity and thermal needs. Whether you are developing nitrogen-doped structures or high-capacity electrodes, our lab high-temp furnaces provide the stability and inert control necessary for professional-grade results.

Ready to optimize your carbonization process? Contact our technical experts today to find the perfect furnace solution for your laboratory.

Visual Guide

References

- Shanshan Ma, Bo You. A pyridinic nitrogen-rich carbon paper for hydrazine oxidation-hybrid seawater electrolysis toward efficient H2 generation. DOI: 10.1007/s40843-023-2762-9

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What critical environmental conditions does a tube atmosphere furnace provide for t-BTO@C carbonization?

- What role does an atmosphere furnace play in industrial-scale production? Unlock Precision in High-Temperature Processing

- Why is a high-temperature atmosphere tube furnace required for the synthesis of Sr2TiO4-NF through ammonolysis?

- What are the controlled atmospheres for heat treatment? Master the Art of Material Transformation

- What are the two main purposes of controlled atmosphere conditions in furnaces? Protect or Transform Materials for Peak Performance

- What is an atmosphere furnace? Achieve Superior Material Processing with Controlled Environments

- Which gases are commonly used to create inert atmospheres in furnaces? Nitrogen vs. Argon Explained

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments