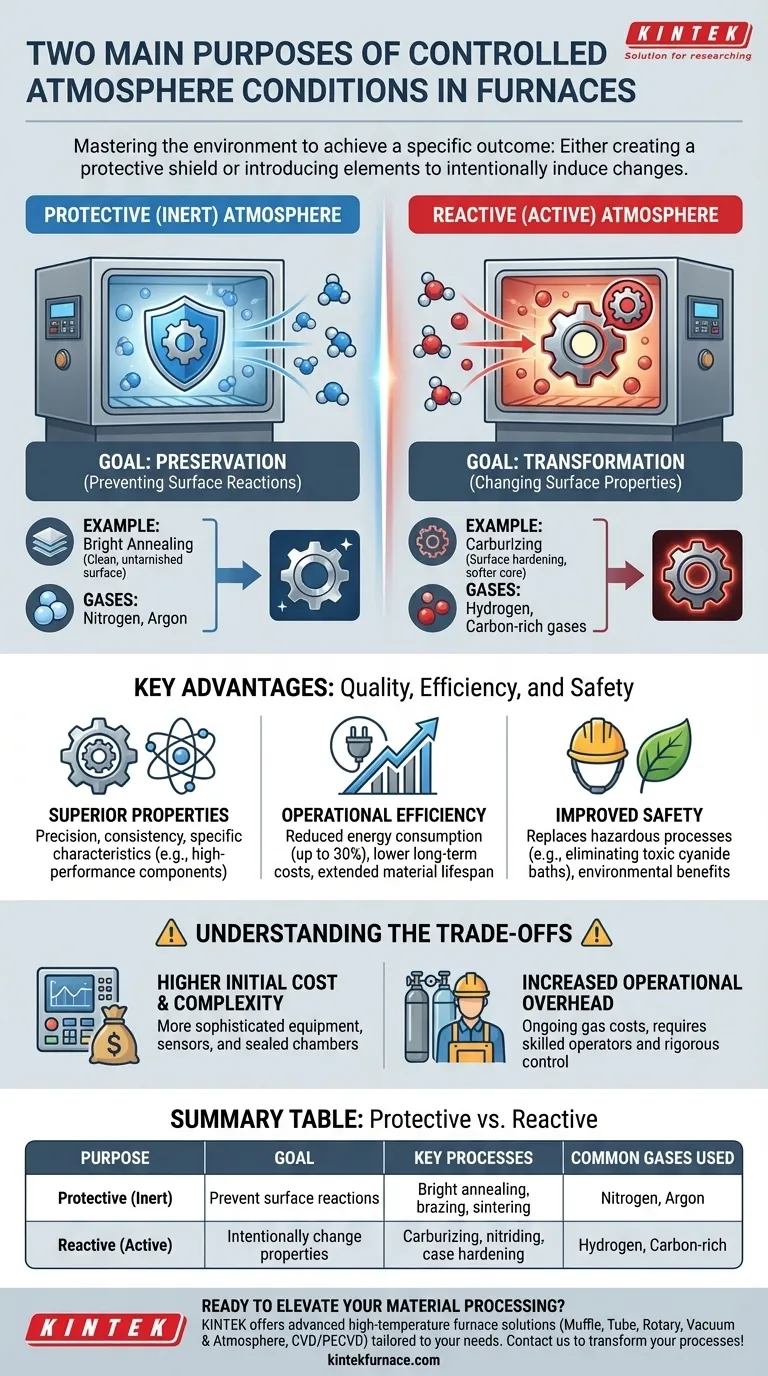

The two primary purposes of a controlled atmosphere furnace are fundamentally opposite yet equally critical. The first is to create a chemically inert environment to protect a material's surface from unwanted reactions, while the second is to create a chemically active environment to intentionally change a material's surface properties. This control is essential for achieving the precise characteristics required in high-performance components.

The decision to use a controlled atmosphere is about mastering the environment to achieve a specific outcome. You are either creating a protective shield to prevent changes like oxidation, or you are introducing specific elements to intentionally induce changes like surface hardening.

The Two Core Functions: Protective vs. Reactive

The choice between a protective or reactive atmosphere dictates the entire heat treatment process and its outcome. Each function serves a distinct manufacturing goal.

The Protective (Inert) Atmosphere

The primary goal here is preservation. By filling the furnace with an inert gas like nitrogen or argon, you displace the oxygen that would normally be present in the air.

This prevents surface reactions, most notably oxidation (rusting or scaling), during high-temperature processes. This is critical for applications like bright annealing, where the material must exit the furnace with a clean, untarnished surface.

The Reactive (Active) Atmosphere

In this case, the goal is transformation. The atmosphere is carefully formulated with specific gases designed to react with the material's surface.

This process intentionally changes the surface chemistry to enhance its properties. A classic example is carburizing, where carbon is diffused into the surface of steel to create a hard, wear-resistant outer layer while maintaining a softer, tougher core.

Why This Control Matters: The Key Advantages

Moving beyond simple heating in air provides significant advantages in quality, efficiency, and safety, which is why these furnaces are standard in demanding industries like aerospace, automotive, and medical manufacturing.

Achieving Superior Material Properties

Precise atmospheric control allows for unparalleled consistency and the creation of specific material characteristics. It enables processes that are simply not possible in an open-air furnace.

This level of precision is non-negotiable for critical components where performance and reliability are paramount.

Increasing Operational Efficiency

Controlled atmosphere furnaces are engineered for high efficiency. By using inert gases for optimized heat distribution and superior insulation, they can reduce energy consumption by up to 30% compared to older methods.

This energy savings, combined with a reduction in rejected parts and an extended lifespan for the materials being processed, leads to significant long-term cost reduction.

Improving Environmental and Worker Safety

This technology offers a major environmental benefit by replacing older, more hazardous processes.

For example, controlled atmosphere carburizing eliminates the need for toxic cyanide salt baths, removing the associated risks of land contamination and the complex, costly disposal of hazardous waste.

Understanding the Trade-offs

While powerful, this technology is not without its considerations. The decision to invest in a controlled atmosphere system involves balancing its benefits against its complexity.

Higher Initial Cost and Complexity

These furnaces are more complex than their open-air counterparts. They require sophisticated gas mixing panels, sealed chambers, and advanced sensors to monitor and maintain the atmosphere.

This results in a higher initial capital investment compared to simpler furnace designs.

Increased Operational Overhead

Managing the gas supply and ensuring the precise atmospheric composition is maintained requires skilled operators and rigorous process control.

The gases themselves—such as nitrogen, argon, or hydrogen—represent an ongoing operational cost that must be factored into the total cost of ownership.

Making the Right Choice for Your Goal

Selecting the right atmospheric approach depends entirely on the desired outcome for your material.

- If your primary focus is preventing oxidation and maintaining surface finish: You need a protective, inert atmosphere for processes like bright annealing, brazing, or sintering.

- If your primary focus is altering the surface chemistry for enhanced performance: You need a reactive atmosphere for processes like case hardening, carburizing, or nitriding.

- If your primary focus is cost-effective, high-volume production of advanced materials: The efficiency, repeatability, and safety benefits of controlled atmosphere furnaces often outweigh their initial cost compared to older, less precise methods.

Ultimately, controlling the furnace atmosphere gives you direct control over the final properties and quality of your material.

Summary Table:

| Purpose | Goal | Key Processes | Common Gases Used |

|---|---|---|---|

| Protective (Inert) | Prevent surface reactions like oxidation | Bright annealing, brazing, sintering | Nitrogen, Argon |

| Reactive (Active) | Intentionally change surface properties | Carburizing, nitriding, case hardening | Hydrogen, Carbon-rich gases |

Ready to elevate your material processing with precise atmospheric control? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Whether you're in aerospace, automotive, or medical manufacturing, we can help you achieve superior material properties, increase efficiency, and enhance safety. Contact us today to discuss how our furnaces can transform your processes!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance