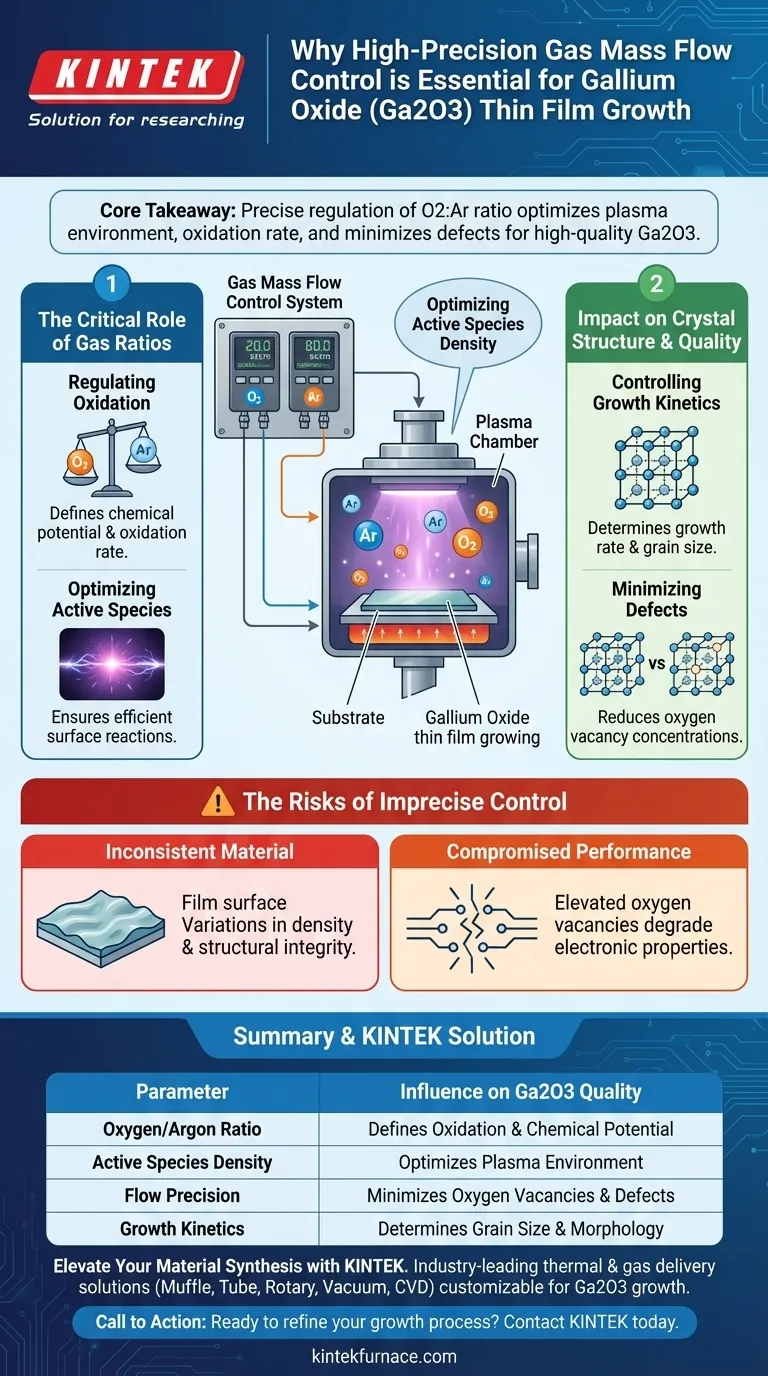

A high-precision gas mass flow control system is essential for accurately regulating the ratio of oxygen (O2) to argon (Ar) during the growth process. This precise regulation allows for fine-tuning of the plasma environment, which directly dictates the oxidation rate and suppresses the formation of structural defects in the final material. Without this control, achieving high-quality Gallium Oxide (Ga2O3) thin films is virtually impossible.

Core Takeaway By optimizing the density of active oxygen species in the plasma, high-precision flow control directly enhances crystal quality, resulting in optimal grain sizes and minimized oxygen vacancies critical for device performance.

The Critical Role of Gas Ratios

Regulating the Oxidation Environment

The fundamental purpose of the mass flow control system is to maintain specific flow ratios between oxygen and argon.

This is not merely about volume; it is about defining the chemical potential of the growth atmosphere.

By locking in the correct oxygen-to-argon ratio, you gain direct control over the oxidation rate of the material.

Optimizing Active Species Density

In plasma-enhanced processes, the gas mixture determines the characteristics of the plasma itself.

Finely adjusting the gas mixture optimizes the density of active oxygen species within the plasma.

These highly active species are required to ensure efficient chemical reactions at the substrate surface.

Impact on Crystal Structure and Quality

Controlling Growth Kinetics

The precise delivery of gas influences how fast and how well the crystal lattice forms.

The flow ratio is a critical parameter for determining the growth rate of the thin film.

It also dictates the grain size, ensuring the material achieves the desired structural morphology.

Minimizing Defects

A major challenge in Gallium Oxide growth is the formation of crystal defects.

High-precision control suppresses defect formation by ensuring a consistent supply of reactants.

Most importantly, it minimizes oxygen vacancy concentrations, which are often detrimental to the film's electronic properties.

The Risks of Imprecise Control

Inconsistent Material Properties

If the gas flow fluctuates, the oxidation rate becomes unstable.

This leads to variations in film density and structural integrity across the wafer.

Compromised Electronic Performance

The electronic quality of Ga2O3 is highly sensitive to stoichiometry.

Imprecise flow control frequently results in elevated oxygen vacancies.

These vacancies act as unintended defects that can degrade the conductivity and breakdown voltage of the final device.

Making the Right Choice for Your Goal

To maximize the quality of your Gallium Oxide thin films, you must align your flow control strategy with your specific material requirements.

- If your primary focus is electrical performance: Prioritize precision to minimize oxygen vacancy concentrations, as these directly impact carrier transport.

- If your primary focus is structural uniformity: Focus on maintaining a stable oxygen-to-argon ratio to ensure optimal grain size and consistent growth rates.

The gas mass flow controller is not a passive component; it is the active regulator of your material's fundamental quality.

Summary Table:

| Parameter Influence | Effect on Ga2O3 Quality |

|---|---|

| Oxygen/Argon Ratio | Defines oxidation rate and chemical potential |

| Active Species Density | Optimizes plasma environment for surface reactions |

| Flow Precision | Minimizes oxygen vacancy concentrations and defects |

| Growth Kinetics | Determines grain size and structural morphology |

Elevate Your Material Synthesis with KINTEK

Precise atmospheric control is the difference between a defective sample and a high-performance semiconductor. KINTEK provides industry-leading thermal and gas delivery solutions tailored for advanced material research.

Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet the rigorous demands of Gallium Oxide growth. Whether you need to minimize oxygen vacancies or optimize grain size, our systems provide the stability your research requires.

Ready to refine your growth process? Contact KINTEK today to discuss your custom high-temperature furnace and gas control needs with our technical team.

Visual Guide

References

- Ren-Siang Jiang, Qijin Cheng. O2-to-Ar Ratio-Controlled Growth of Ga2O3 Thin Films by Plasma-Enhanced Thermal Oxidation for Solar-Blind Photodetectors. DOI: 10.3390/nano15181397

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What is the role of a Horizontal Tube LPCVD in solar cells? Unlock High-Efficiency Bifacial Cell Fabrication

- What are the different substrate heating methods in CVD? Hot Wall vs. Cold Wall Explained

- What is the operating principle of a Quartz Crystal Thickness Monitor? Achieve Precise ZTO Thin Film Control

- What are the equipment for chemical vapor deposition? A Guide to the 5 Essential Components

- What are the advantages of using a CVD tube furnace for preparing gate media? Achieve Superior Film Control and Purity

- What are the practical applications of gate media prepared by CVD tube furnaces? Unlock Advanced Electronics and More

- What factors are important for maximizing CVD coating performance? Achieve Superior Coating Quality and Durability

- What is the function of a Liquid Source Chemical Vapor Deposition (LSCVD) system? Precision CNT Synthesis for Composites