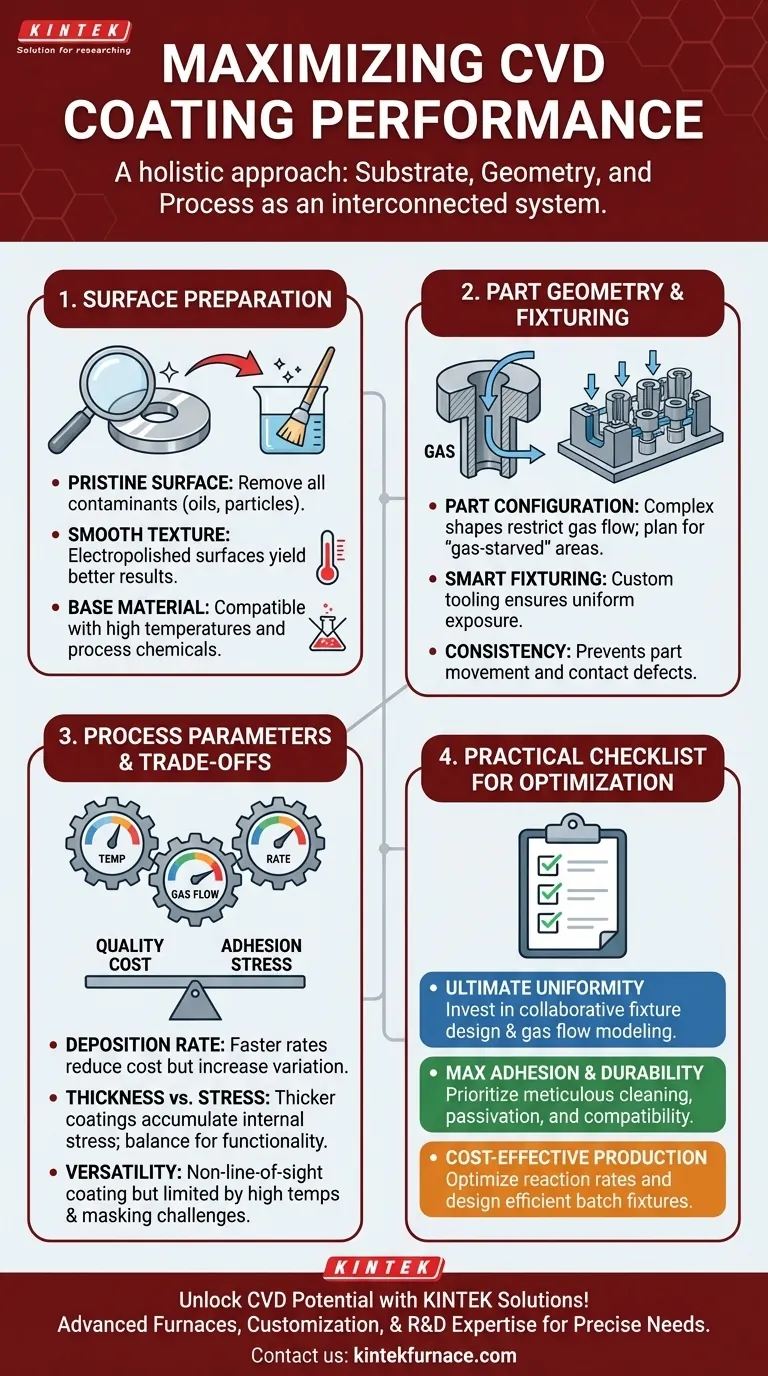

To maximize the performance of a Chemical Vapor Deposition (CVD) coating, you must systematically control three critical areas: the initial state of the part, its physical design and handling, and the specific parameters of the deposition process itself. Success depends on meticulous surface preparation, intelligent fixturing to ensure uniform exposure, and balancing process variables like temperature and gas flow to achieve the desired thickness and adhesion without introducing stress.

Achieving a high-performance CVD coating is not the result of a single adjustment. It is the outcome of a holistic approach that treats the substrate, the component geometry, and the chemical process as an interconnected system.

The Foundation: Substrate and Surface Preparation

The final coating is fundamentally bonded to the substrate, making the initial surface condition the most critical starting point for success.

Why Surface Condition is Paramount

A pristine surface is non-negotiable. Any contaminants, from oils to microscopic particles, must be thoroughly removed before the part enters the coating chamber.

The texture of the surface also plays a significant role. Smoother, electropolished surfaces generally yield more consistent and reliable coating results compared to rough or uneven surfaces.

The Role of the Base Material

The high temperatures required for the CVD process (often several hundred degrees Celsius) limit the types of base materials that can be coated without warping or altering their properties.

Furthermore, the base material is an active participant in the chemical reaction. Different materials, such as standard stainless steel versus more exotic alloys, can react differently with the precursor gases, influencing adhesion and the final coating structure.

The Blueprint: Part Geometry and Fixturing

How a part is shaped and held inside the reactor directly impacts the final coating quality and uniformity.

How Part Configuration Dictates Uniformity

CVD relies on precursor gases flowing around the part to deposit the coating. Complex geometries with features like narrow bores, deep crevices, or blind holes can restrict this gas flow.

These "gas-starved" areas will inherently receive a thinner coating than exposed, open surfaces. Understanding and planning for this effect is crucial for parts with intricate designs.

Fixturing: The Unsung Hero of Consistency

Fixturing is the custom tooling that holds parts securely within the CVD reactor. Its importance cannot be overstated.

Proper fixture design ensures every part is held in the optimal position for uniform gas exposure, preventing part-to-part variation. It also prevents parts from moving or touching, which would cause defects and inconsistencies in the coating. Effective fixturing is a direct investment in quality and repeatability.

Understanding the Inherent Trade-offs

Maximizing one aspect of CVD performance often requires compromising on another. Understanding these trade-offs is key to making informed decisions.

Quality vs. Cost and Speed

The rate of the coating reaction is a primary lever for balancing time, cost, and quality. A faster deposition process can reduce cycle time and cost, but it can also lead to greater variation in coating thickness across the part.

Slower, more controlled deposition cycles generally produce a more uniform and higher-quality film, but at a higher cost per part.

Adhesion vs. Internal Stress

CVD creates an exceptionally strong chemical bond, resulting in superior adhesion to the substrate. However, as the coating film builds in thickness, internal stresses also accumulate.

If the coating becomes too thick, this internal stress can exceed the material's strength, leading to cracking or delamination. Therefore, film thickness is always a balance between the desired functional properties and the physical limits of stress.

Versatility vs. Process Constraints

One of CVD's greatest strengths is its non-line-of-sight nature, allowing it to uniformly coat complex internal and external surfaces.

However, the high process temperatures can limit substrate choices, and effectively masking specific areas of a part to prevent coating can be significantly more challenging than with other methods like Physical Vapor Deposition (PVD).

A Practical Checklist for Maximizing Performance

Use your primary engineering goal to focus your optimization efforts where they will have the most impact.

- If your primary focus is ultimate uniformity across a complex part: Invest heavily in collaborative fixture design and modeling gas flow behavior.

- If your primary focus is maximum adhesion and durability: Prioritize meticulous pre-cleaning, surface passivation, and confirming substrate-coating chemical compatibility.

- If your primary focus is cost-effective mass production: Concentrate on optimizing reaction rates and designing batch fixtures that maximize chamber capacity without compromising quality.

By treating these factors as an integrated system, you can transform CVD from a complex process into a predictable and powerful manufacturing tool.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Substrate & Surface Preparation | Pristine surface, material compatibility, high-temperature limits |

| Part Geometry & Fixturing | Uniform gas flow, fixture design for consistency, handling complex shapes |

| Deposition Process Parameters | Temperature, gas flow, thickness control, stress management |

| Trade-offs | Quality vs. cost, adhesion vs. stress, versatility vs. constraints |

Unlock the full potential of your CVD processes with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like CVD/PECVD, Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces. Our deep customization capability ensures precise alignment with your unique experimental needs, enhancing coating performance, durability, and efficiency. Ready to elevate your results? Contact us today for a tailored consultation!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What temperature ranges can a CVD Tube Furnace achieve with different tube materials? Unlock High-Temp Precision for Your Lab

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- What types of atmosphere control does a CVD Tube Furnace support? Master Vacuum and Gas Control for Precision

- Where is a CVD Tube Furnace commonly used? Essential for High-Tech Materials and Electronics

- What is the working principle of a CVD tube furnace? Achieve Precise Thin Film Deposition for Your Lab