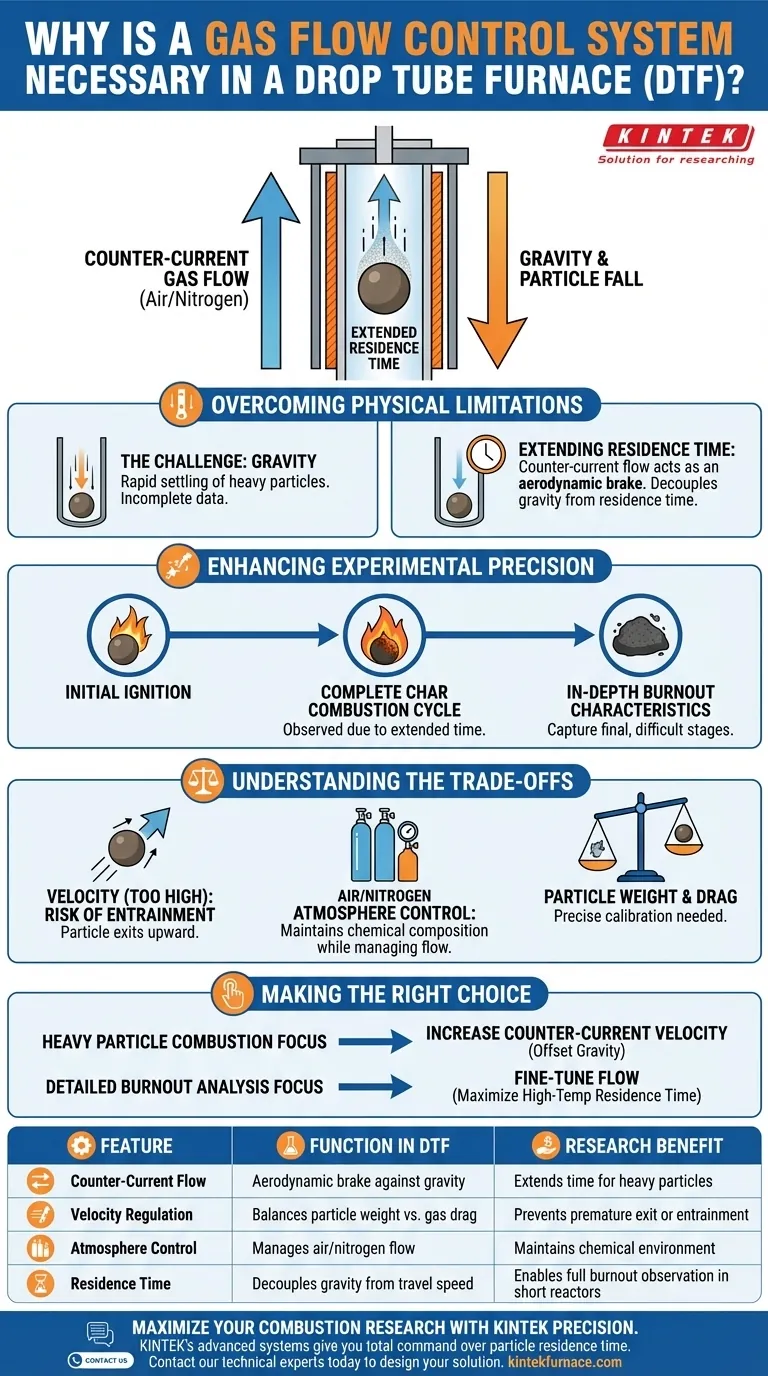

A gas flow control system is essential in a Drop Tube Furnace (DTF) to decouple the particle's residence time from the acceleration of gravity. It regulates the direction and velocity of the atmosphere—typically air or nitrogen—to counteract the rapid settling of large, heavy particles. This control mechanism allows researchers to retain samples in the heating zone long enough to observe processes that would otherwise require a much taller furnace.

By precisely manipulating counter-current gas velocity, you can offset gravitational forces and significantly extend the residence time of heavy particles. This enables the observation of complete char combustion and deep burnout characteristics within the limited physical height of the furnace chamber.

Overcoming Physical Limitations

The Challenge of Gravity

In a standard Drop Tube Furnace, large particles—such as heavy wheat straw nodes—are subject to rapid gravitational settling.

Without intervention, these heavy particles fall through the heated section too quickly.

This results in incomplete data, as the particle exits the furnace before the combustion cycle is finished.

Extending Residence Time

The primary function of the gas flow control system is to generate a counter-current force.

By directing gas flow upward against the falling particle, the system acts as an aerodynamic brake.

This artificially extends the residence time of the particle within the high-temperature zone, compensating for the furnace's limited height.

Enhancing Experimental Precision

capturing the Complete Combustion Cycle

To understand fuel behavior, researchers must observe the entire process, not just the initial ignition.

Flow control ensures the particle remains in the hot zone through the complete char combustion stage.

This is critical for accurate modeling of how heavy biomass fuels behave in real-world boilers.

In-Depth Burnout Characteristics

Burnout is the final and often most difficult stage of combustion to analyze in a short reactor.

By slowing the particle's descent, the system provides the necessary time window to measure in-depth burnout characteristics.

This allows for the collection of data that would otherwise be lost if the particle fell at its natural terminal velocity.

Understanding the Trade-offs

Balancing Velocity and Entrainment

While counter-current flow is necessary for heavy particles, it introduces operational sensitivity.

If the gas velocity is set too high, you risk entrainment, where the particle is blown upward out of the reaction zone entirely.

The system requires precise calibration to balance the weight of the specific particle against the drag force of the gas.

Complexity of Atmosphere Control

The system must manage flow velocity without compromising the chemical composition of the atmosphere.

Whether using air (oxidative) or nitrogen (inert), the flow rate must be adjusted to maintain the correct aerodynamic profile.

This adds a layer of complexity to the experimental setup, requiring careful monitoring of mass flow controllers.

Making the Right Choice for Your Goal

To maximize the effectiveness of your Drop Tube Furnace experiments, align your flow strategy with your specific research targets:

- If your primary focus is heavy particle combustion: Increase counter-current gas velocity to offset gravity and ensure the particle does not exit the furnace before ignition is complete.

- If your primary focus is detailed burnout analysis: Fine-tune the flow to maximize residence time in the high-temperature zone, allowing for the observation of the final stages of char consumption.

Precise aerodynamic control effectively transforms a physically short furnace into a capability-rich environment for analyzing long-duration combustion processes.

Summary Table:

| Feature | Function in DTF | Research Benefit |

|---|---|---|

| Counter-Current Flow | Acts as an aerodynamic brake against gravity | Extends residence time for heavy particles |

| Velocity Regulation | Balances particle weight vs. gas drag | Prevents premature exit or upward entrainment |

| Atmosphere Control | Manages air or nitrogen flow rates | Maintains chemical environment for combustion/pyrolysis |

| Residence Time | Decouples gravity from particle travel speed | Enables observation of full burnout in short reactors |

Maximize Your Combustion Research with KINTEK Precision

Don't let physical furnace height limit your data. KINTEK’s advanced gas flow control systems are designed to give you total command over particle residence time and burnout characteristics. Backed by expert R&D and manufacturing, KINTEK offers customizable Drop Tube, Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your specific lab requirements.

Ready to achieve superior experimental precision? Contact our technical experts today to design a high-temperature solution that fits your unique research needs.

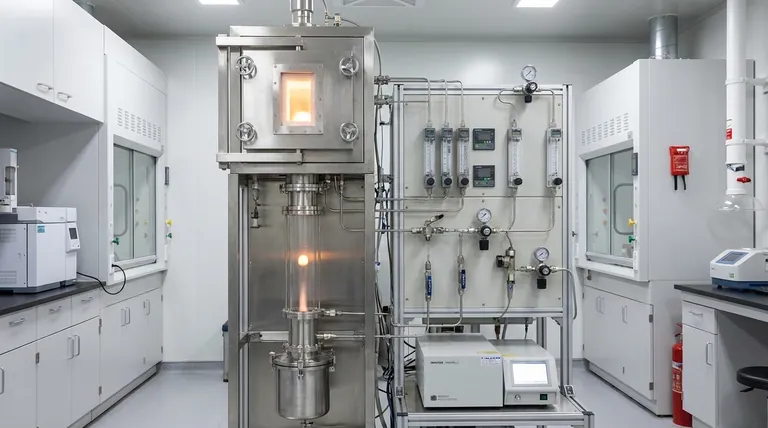

Visual Guide

References

- Haoteng Zhang, Chunjiang Yu. Experimental Study on Single-Particle Combustion Characteristics of Large-Sized Wheat Straw in a Drop Tube Furnace. DOI: 10.3390/en18153968

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the purpose of a two-zone tube furnace for nanoparticle selenization? Achieve Precision Vapor Control

- What are the process advantages of using a horizontal tube pyrolysis reactor? Maximize Precision and Data Integrity

- What are the advantages of using a condensing tube furnace for magnesium extraction? Achieve High Purity and Efficient Metal Recovery

- What are the dimensions and temperature capabilities of single zone horizontal tube furnace models? Explore Key Specs for Your Lab

- What materials are used for the tube chamber in tubular furnaces? Choose the Right Tube for Your Lab's High-Temp Needs

- What does the horizontal orientation refer to in tube furnaces? Discover Its Benefits and Applications

- How is the structure of a multi station vacuum tube furnace divided? Optimize Your Lab's Thermal Processing

- What role does a tube furnace play in the high-temperature heat treatment of vermiculite? Precision Control Expert