High-temperature tensile testing of tungsten demands exceptional thermal precision. A furnace system equipped with multiple thermocouples is strictly necessary to guarantee temperature uniformity across the entire gauge length of the sample. This setup minimizes thermal fluctuations during the loading phase, which is critical for generating valid, reproducible data.

Tungsten’s mechanical properties are hypersensitive to thermal variations. Multiple thermocouples ensure the temperature remains uniform across the sample, preventing distorted stress-strain data and allowing for the accurate assessment of yield strength and creep effects.

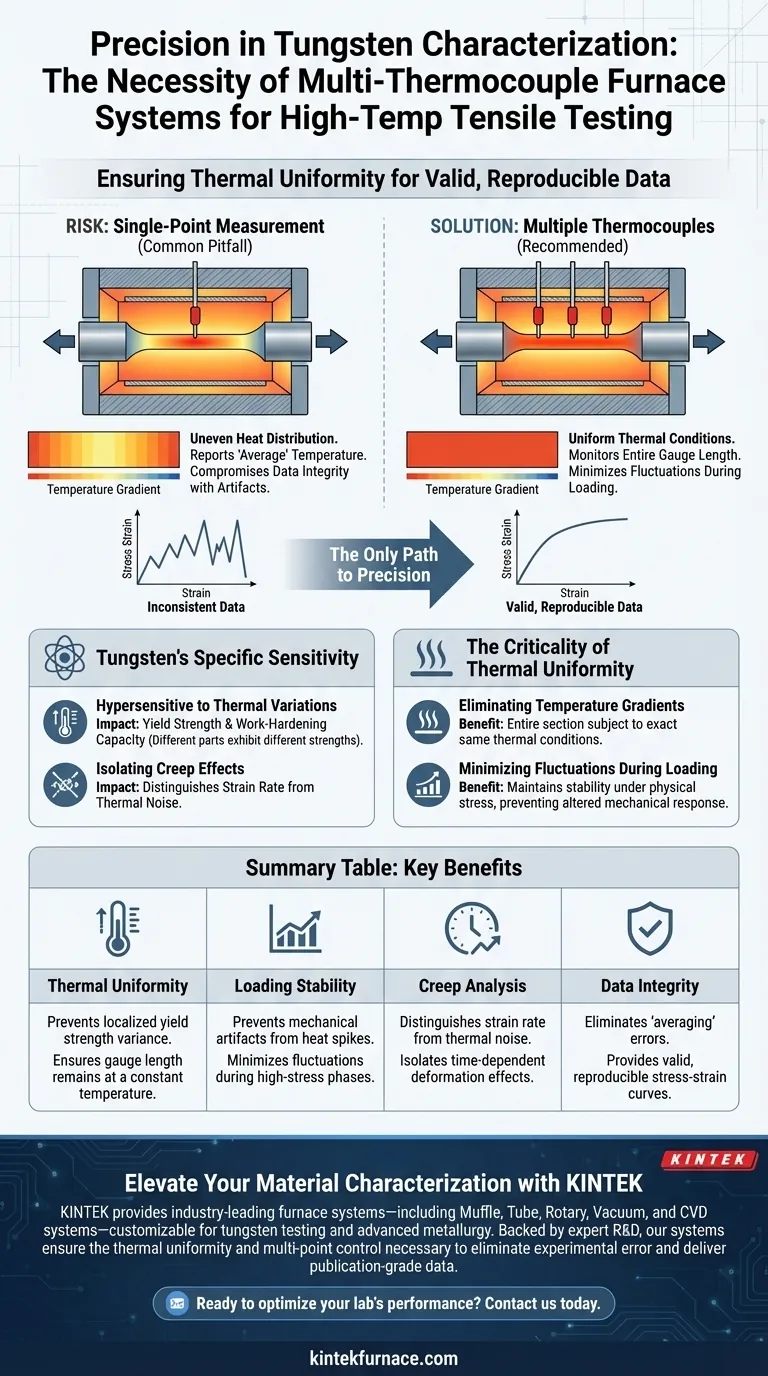

The Criticality of Thermal Uniformity

Eliminating Temperature Gradients

In high-temperature testing, heat does not naturally distribute evenly. Using multiple thermocouples allows you to monitor the temperature at various points along the sample's gauge length.

This ensures that the entire section of the tungsten being tested is subject to the exact same thermal conditions. Without this multi-point monitoring, significant temperature gradients could exist undetected between the center and the ends of the sample.

Minimizing Fluctuations During Loading

The test environment must remain stable while the sample is under physical stress. Multiple sensors provide a feedback loop that helps maintain minimal fluctuations throughout the loading process.

This stability prevents the mechanical response of the material from being altered by sudden spikes or drops in temperature during the test.

Tungsten's Specific Sensitivity

Impact on Yield Strength and Work-Hardening

Tungsten is not a material that tolerates approximation. Its mechanical properties, specifically yield strength and work-hardening capacity, are highly sensitive to even minor temperature changes.

If the temperature varies along the gauge length, different parts of the sample will exhibit different yield strengths. This results in unreliable nominal stress-strain curves that do not accurately represent the material's true behavior.

Isolating Creep Effects

Accurate thermal data is essential for analyzing time-dependent deformation. The multi-thermocouple configuration allows for the precise comparison of creep effects across different strain rates.

If the temperature is not uniform, it becomes impossible to distinguish whether deformation is caused by the applied strain rate or by thermal inconsistencies.

Common Pitfalls to Avoid

The Risk of Single-Point Measurement

Relying on a single thermocouple is a significant experimental risk. It may indicate the correct temperature at the center of the sample while the ends remain cooler or run hotter.

This leads to "averaging" errors where the reported test temperature does not reflect the actual condition of the material undergoing failure.

Data Contamination

Inconsistent temperatures lead to compromised data integrity. When thermal conditions fluctuate, the resulting stress-strain curves will show artifacts that look like material properties but are actually experimental errors.

For tungsten, this renders the data useless for high-precision engineering applications.

Making the Right Choice for Your Goal

To ensure your high-temperature tungsten testing yields publication-grade data, align your setup with your specific analytical goals:

- If your primary focus is Establishing Nominal Stress-Strain Curves: Ensure multiple thermocouples cover the full gauge length to prevent temperature-induced variances in yield strength and work-hardening data.

- If your primary focus is Creep Analysis: Use the thermal stability provided by the system to accurately compare creep effects across varying strain rates without thermal noise.

Precision in temperature measurement is the only path to precision in tungsten characterization.

Summary Table:

| Feature | Impact on Tungsten Testing | Benefit of Multiple Thermocouples |

|---|---|---|

| Thermal Uniformity | Prevents localized yield strength variance | Ensures gauge length remains at a constant temperature |

| Loading Stability | Prevents mechanical artifacts from heat spikes | Minimizes fluctuations during high-stress phases |

| Creep Analysis | Distinguishes strain rate from thermal noise | Isolates time-dependent deformation effects |

| Data Integrity | Eliminates "averaging" errors from single points | Provides valid, reproducible stress-strain curves |

Elevate Your Material Characterization with KINTEK

Precision in high-temperature testing starts with the right thermal environment. KINTEK provides industry-leading furnace systems—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to meet the rigorous demands of tungsten testing and advanced metallurgy.

Backed by expert R&D and manufacturing, our systems ensure the thermal uniformity and multi-point control necessary to eliminate experimental error and deliver publication-grade data.

Ready to optimize your lab's performance? Contact us today to discuss your unique testing requirements and discover how our high-temperature solutions can bring unmatched accuracy to your research.

Visual Guide

References

- James R. Miller, T.W. Clyne. Profilometry‐Based Indentation Plastometry Testing of Tungsten at High Temperature. DOI: 10.1002/adem.202500292

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the main types of metal heating elements and their properties? Choose the Right Alloy for Your Heating Needs

- What role do high temperature heating elements play in modern manufacturing processes? Unlock Precision and Quality in Material Production

- What are strip heaters and their features? Discover Versatile Heating Solutions for Your Industrial Needs

- What are the properties of Aluminum Nitride (AlN) when used in ceramic heating elements? Achieve Precision & Safety

- Why is a specifically designed radiation heater preferred over direct sample heating? | Optimize Nanomaterial Synthesis

- What factors should be considered when choosing between MoSi2 and SiC heating elements for sintering furnaces? Optimize Your Sintering Process

- How do ceramic heating elements work? Unlock Efficient, Durable Heat Solutions

- What are the key characteristics of molybdenum disilicide (MoSi2) heating elements? Unlock High-Temp Performance