At their core, metal heating elements fall into two primary categories: nickel-chromium (NiCr) alloys and copper-nickel (CuNi) alloys. The fundamental difference lies in their intended operating temperature and environment. NiCr is the industry standard for high-temperature applications due to its ability to resist oxidation when red-hot, while CuNi is valued for its stability and corrosion resistance in low-temperature systems.

Choosing the right metal heating element is a direct trade-off between operating temperature and electrical resistivity. High-temperature applications demand high resistivity and oxidation resistance (NiCr), while low-temperature systems prioritize stability and corrosion resistance (CuNi).

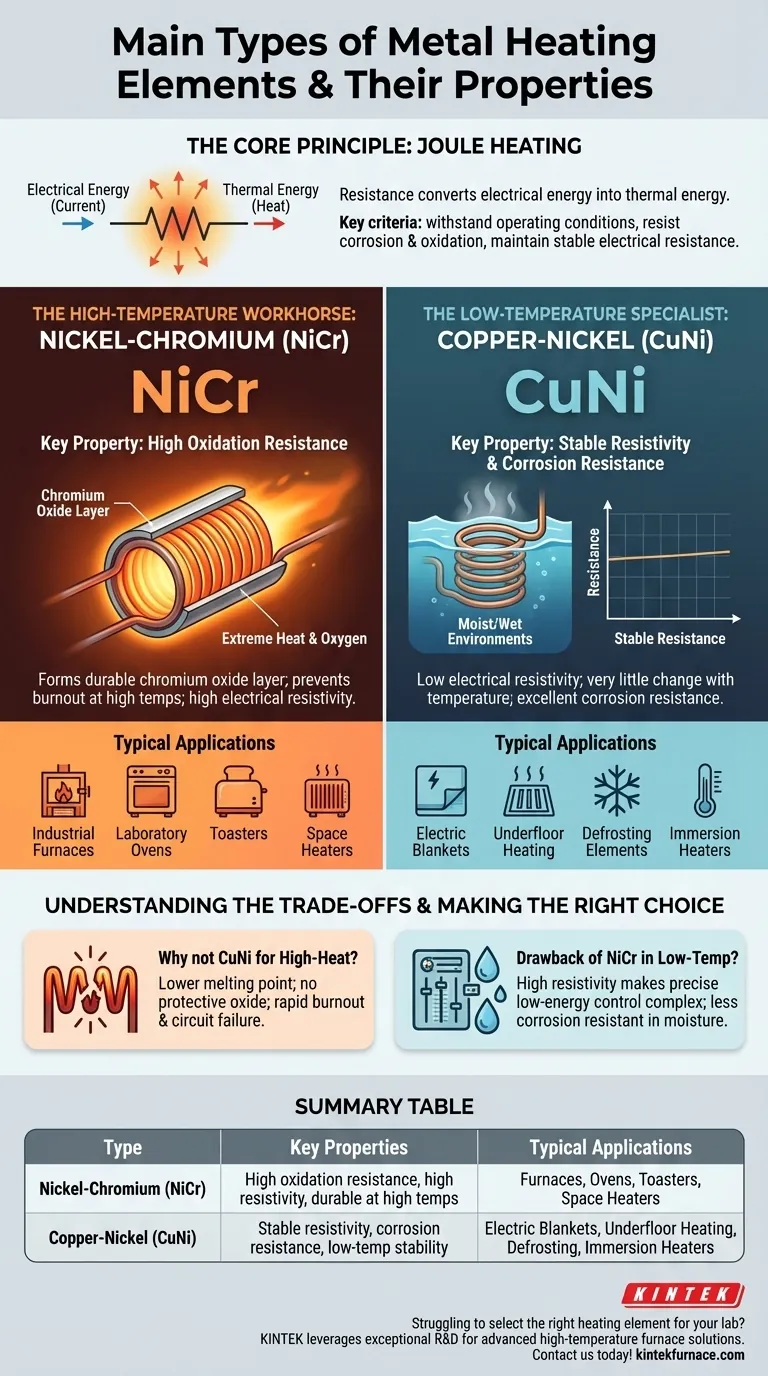

The Core Principle: Joule Heating

How Resistance Creates Heat

All electric heating elements operate on a principle known as Joule heating. This process describes how the resistance of a material to the flow of electrical current converts electrical energy directly into thermal energy, or heat.

Why Material Choice is Critical

An ideal heating element must not only generate heat efficiently but also withstand its own operating conditions. Key selection criteria include the ability to resist high temperatures without melting, prevent corrosion and oxidation, and maintain a stable electrical resistance over its service life.

The High-Temperature Workhorse: Nickel-Chromium (NiCr)

Key Property: High Oxidation Resistance

NiCr alloys, often known by the trade name Nichrome, are the default choice for high-temperature heating. Their high electrical resistivity allows them to generate significant heat quickly.

More importantly, when heated, NiCr forms a durable, adherent outer layer of chromium oxide. This layer protects the underlying metal from further oxidation, preventing it from burning out even at extreme temperatures.

Typical Applications

Because of its durability at high heat, NiCr is found in devices where intense, radiant heat is the goal. This includes industrial furnaces, laboratory ovens, toasters, and electric space heaters.

The Low-Temperature Specialist: Copper-Nickel (CuNi)

Key Property: Stable Resistivity and Corrosion Resistance

CuNi alloys, such as Constantan, have a much lower electrical resistivity compared to NiCr. Their resistance also changes very little with temperature, making them ideal for applications requiring precise and stable thermal control.

Furthermore, CuNi exhibits excellent resistance to corrosion, making it a reliable choice for use in moist or wet environments where other metals would quickly degrade.

Typical Applications

CuNi is used where gentle, controlled, and reliable heat is needed. Common examples include electric blankets, underfloor heating systems, defrosting elements, and immersion heaters for liquids.

Understanding the Trade-offs

Why You Can't Use CuNi for High-Heat

Using a CuNi alloy in a high-temperature application like a furnace would lead to rapid failure. It has a lower melting point than NiCr and, critically, does not form a protective oxide layer, causing it to quickly burn through and break the electrical circuit.

The Drawback of NiCr in Low-Temp Systems

While NiCr could be used for low-temperature heating, it is often suboptimal. Its high resistivity can make precise, low-energy control more complex. For applications requiring exposure to moisture, the superior corrosion resistance of CuNi makes it the far more durable and reliable choice.

Making the Right Choice for Your Application

The selection between these two alloy families is not about which is "better" but which is engineered for your specific goal.

- If your primary focus is high-temperature output (above 400°C / 750°F): Nickel-chromium (NiCr) is the required choice for its superior oxidation resistance and structural integrity at high heat.

- If your primary focus is low-temperature, controlled heating or corrosion resistance: Copper-nickel (CuNi) provides the necessary stability and durability, especially in potentially wet environments.

By matching the alloy's fundamental properties to your operational demands, you ensure both system performance and longevity.

Summary Table:

| Type | Key Properties | Typical Applications |

|---|---|---|

| Nickel-Chromium (NiCr) | High oxidation resistance, high electrical resistivity, durable at high temperatures | Industrial furnaces, laboratory ovens, toasters, electric space heaters |

| Copper-Nickel (CuNi) | Stable resistivity, excellent corrosion resistance, low-temperature stability | Electric blankets, underfloor heating, defrosting elements, immersion heaters |

Struggling to select the right heating element for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental requirements. Contact us today to enhance your laboratory's efficiency and performance!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance