In short, Microwave Plasma Chemical Vapor Deposition (MPCVD) is a leading method for creating diamond thin films because it produces exceptionally pure material with a high degree of control. It achieves this by using microwaves to generate a clean, dense, and stable plasma without the contaminating electrodes or filaments found in other techniques, ensuring the resulting diamond is of the highest quality.

The core advantage of MPCVD is its ability to create a high-energy plasma that is physically isolated from any internal hardware. This electrode-less design is the key to preventing contamination, resulting in diamond films with unparalleled purity and structural integrity.

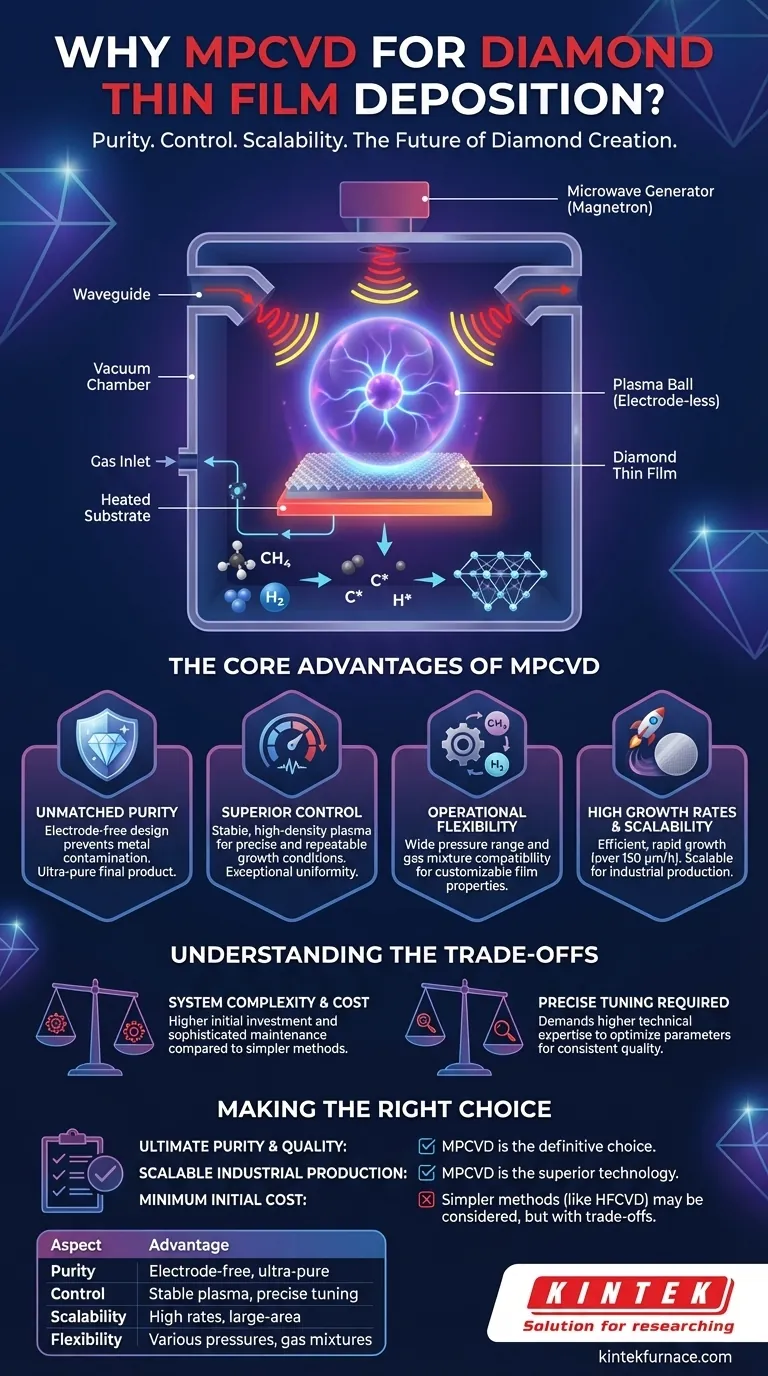

The Core Principle: How MPCVD Works

To understand why MPCVD is so effective, we must first understand its fundamental mechanism. The process is a sophisticated application of plasma physics to material science.

Generating Plasma with Microwaves

An MPCVD system uses a magnetron—the same component found in a microwave oven—to generate high-power microwaves. These are channeled into a vacuum chamber containing a substrate and a mixture of gases, typically a small amount of methane in a large amount of hydrogen.

The intense microwave energy excites the gas, stripping electrons from their atoms and creating a glowing ball of plasma.

Decomposing Gases for Deposition

Within this plasma, the oscillating electromagnetic field causes electrons to collide violently with the gas molecules. This process efficiently breaks down the precursor gases (methane and hydrogen) into highly reactive species, including carbon radicals and atomic hydrogen.

The atomic hydrogen plays a crucial role by selectively etching away any non-diamond carbon (graphite) that tries to form, ensuring a pure diamond structure grows.

Forming the Diamond Film

The desired carbon radicals then land on a heated substrate placed within the chamber. Under precisely controlled temperature and pressure, these radicals bond together, arranging themselves into the strong tetrahedral lattice of a diamond crystal. This process continues layer by layer, forming a high-quality diamond film.

Key Advantages Over Other Methods

MPCVD's unique approach provides several distinct advantages that set it apart from older methods like Hot Filament CVD (HFCVD) or DC Arc Jet CVD.

Unmatched Purity: The Electrode-Free Advantage

The most significant advantage is the avoidance of contamination. Methods like HFCVD use a hot tungsten filament inside the chamber, which can degrade and introduce metal impurities into the diamond film. MPCVD has no internal electrodes or filaments.

Because the plasma is generated and contained by an electromagnetic field, it does not touch the chamber walls, further preventing contamination and ensuring an ultra-pure final product.

Superior Plasma Control and Stability

MPCVD generates a high-density, large-area, and highly stable plasma. This stability allows for precise and repeatable control over growth conditions.

The result is exceptional uniformity across the entire substrate, which is critical for industrial applications where consistent material properties are required over large wafers.

Operational Flexibility

The method operates effectively across a wide range of pressures and is compatible with various gas mixtures. This flexibility allows researchers and engineers to fine-tune the film's properties, such as grain size, stress, and electrical characteristics, for specific applications.

High Growth Rates and Scalability

Modern MPCVD systems can achieve very high growth rates, sometimes exceeding 150 micrometers per hour. This efficiency, combined with the ability to produce large-area films, makes the process highly scalable for both laboratory research and high-volume industrial production.

Understanding the Trade-offs

While MPCVD is powerful, it is essential to recognize its associated complexities. No technology is without trade-offs.

System Complexity and Initial Cost

An MPCVD reactor is a complex piece of equipment. It requires a microwave generator, waveguides, a vacuum system, precise gas flow controllers, and temperature monitoring systems like optical pyrometers.

This complexity generally translates to a higher initial investment and more sophisticated maintenance compared to simpler systems like HFCVD.

The Need for Precise Tuning

Achieving optimal, stable plasma requires careful engineering and tuning of the microwave cavity and power delivery. Factors like chamber geometry, pressure, and gas composition must be perfectly balanced.

This means that operating an MPCVD system effectively requires a higher level of technical expertise to dial in the specific parameters for consistent, high-quality growth.

Making the Right Choice for Your Goal

Ultimately, the choice of deposition method depends on your primary objective. Understanding the strengths of MPCVD allows you to align the technology with your project's needs.

- If your primary focus is ultimate film purity and quality: MPCVD is the definitive choice due to its contamination-free, highly controlled plasma environment.

- If your primary focus is scalable industrial production: The high growth rates, large-area uniformity, and repeatability of MPCVD make it the superior technology for manufacturing.

- If your primary focus is minimizing initial capital cost for basic experiments: A simpler method like HFCVD may be considered, but you must be prepared to accept the inherent trade-off in potential film contamination and process control.

By leveraging clean energy to create a pristine growth environment, MPCVD empowers the creation of next-generation diamond materials.

Summary Table:

| Aspect | Advantage |

|---|---|

| Purity | Electrode-free design prevents contamination, ensuring ultra-pure diamond films. |

| Control | Stable plasma allows precise tuning of growth conditions for uniform, high-quality films. |

| Scalability | High growth rates and large-area deposition support efficient industrial production. |

| Flexibility | Operates across various pressures and gas mixtures for customizable film properties. |

Unlock the potential of MPCVD for your laboratory or industrial needs! KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental requirements, delivering high-purity diamond films with enhanced efficiency and scalability. Contact us today to discuss how our tailored solutions can elevate your research and production outcomes!

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- What is the role of inert gas doping in the MPCVD method? Accelerate Single-Crystal Diamond Growth

- What is the relationship between diamond growth rate and quality in the MPCVD method? Balancing Speed and Purity for Your Application

- In which industries is the microwave plasma chemical vapor deposition system commonly used? Unlock High-Purity Material Synthesis

- How is CVD classified based on physical characteristics of vapor? Explore AACVD and DLICVD Methods

- Why is the temperature control system important in MPCVD equipment? Ensure Precise Diamond Growth and Process Stability