In short, high temperatures are used in rotary kilns to supply the necessary energy to force a chemical reaction or physical phase change in a material. This process fundamentally transforms the raw feed into a finished product with entirely new, valuable properties that would not exist at normal temperatures.

The core purpose of a rotary kiln isn't just to heat a material, but to use precisely controlled high temperatures as a tool. This thermal energy drives specific, often energy-intensive, transformations that are essential for creating products like cement, lime, and refined minerals.

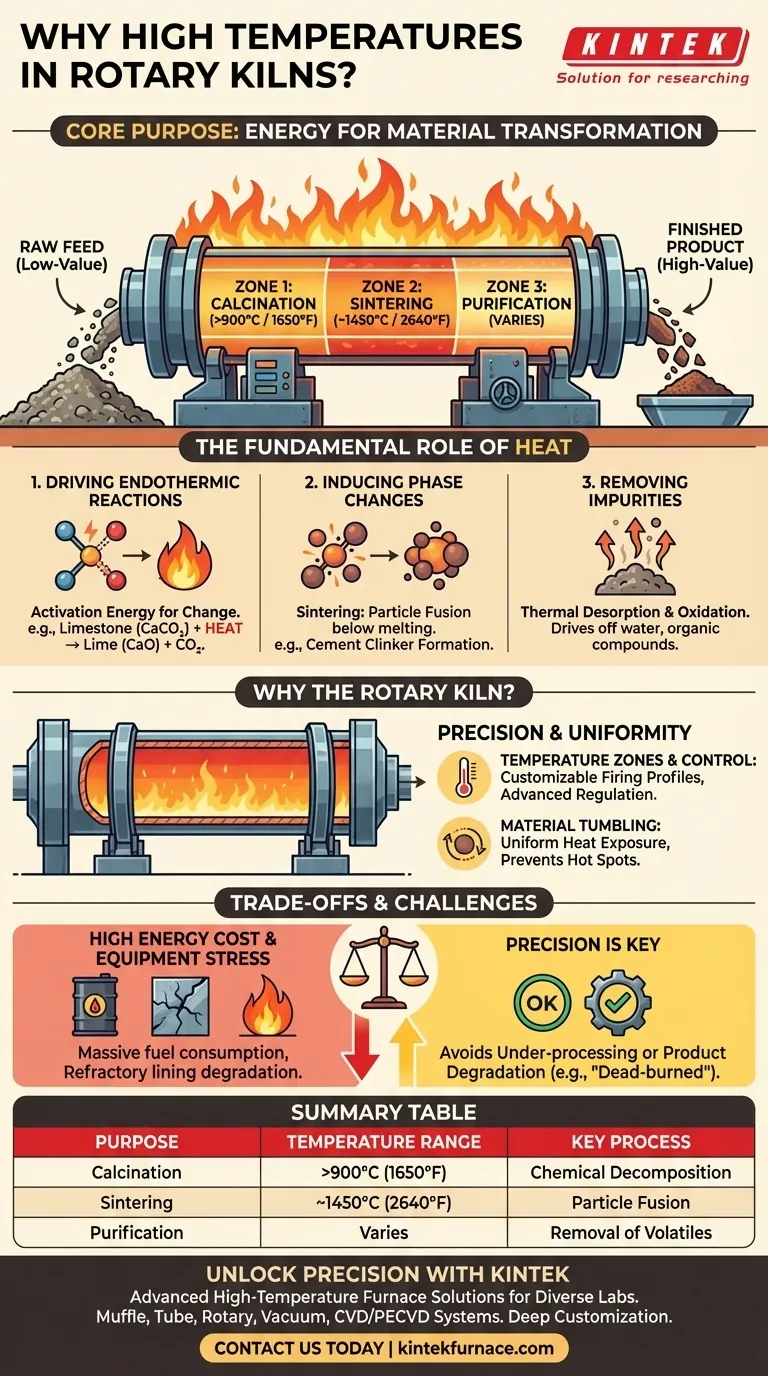

The Fundamental Role of Heat in Material Transformation

To understand the rotary kiln, you must first understand the role of thermal energy. High temperature is the primary catalyst that enables the desired changes in the material being processed.

Driving Endothermic Chemical Reactions

Many crucial industrial processes are endothermic, meaning they require a constant input of energy to occur. The high-temperature environment inside a kiln provides this activation energy.

A classic example is calcination, where limestone (CaCO3) is heated to produce lime (CaO) and carbon dioxide (CO2). This reaction will not happen at a meaningful rate without temperatures exceeding 900°C (1650°F).

Inducing Physical Phase Changes

Heat is also used to change the physical state of a material. This can involve melting, but more often in kilns, it involves sintering.

Sintering is a process where particles fuse together at a temperature just below their melting point. In cement production, a mix of raw materials is heated to around 1450°C (2640°F) to form a semi-molten mass that, upon cooling, becomes cement clinker—a new material with the desired hydraulic properties.

Removing Volatiles and Impurities

Heat is an effective purification tool. It is used to drive off unwanted components, a process known as thermal desorption.

This can be as simple as removing residual water (drying) or as complex as oxidation, where unwanted organic compounds or elements are burned off, leaving behind a more concentrated and valuable final product.

Why the Rotary Kiln is the Ideal Tool

While other furnaces can get hot, the rotary kiln's design is uniquely suited for large-scale, continuous thermal processing. Its effectiveness comes from its ability to manage heat application with precision.

Ensuring Temperature Precision and Control

A rotary kiln is not a simple, uniformly heated tube. It is designed with distinct temperature zones, allowing for a customizable firing profile.

Advanced control systems and mechanisms like cooling air injection ensure the temperature is precisely regulated along the length of the kiln. This prevents under-processing, which leaves the reaction incomplete, and over-processing, which can ruin the final product.

Facilitating Heat Transfer and Material Mixing

The slow rotation of the kiln is critical. It continuously tumbles the material, lifting it through the hot gases and bringing it into contact with the hot refractory walls.

This tumbling action ensures uniform heat exposure for every particle, preventing hot spots and promoting a consistent chemical reaction throughout the entire batch. It also facilitates the release of gases produced during the reaction.

Understanding the Trade-offs

The use of high temperatures is effective but comes with significant operational challenges and costs.

High Energy Consumption

Achieving and maintaining temperatures over 1400°C requires a massive amount of fuel (such as coal, petcoke, or natural gas). Energy is often the single largest operational cost for a kiln-based facility.

Material and Equipment Stress

Extreme heat places enormous stress on the kiln's components. The steel shell must be protected by a durable refractory lining, which degrades over time and requires periodic, costly replacement.

Risk of Product Degradation

While heat is necessary, too much of it can be destructive. For example, "dead-burned" lime or dolomite is produced at such a high temperature that its reactivity is severely reduced. Precise control is therefore not a luxury but a necessity for quality assurance.

Making the Right Choice for Your Goal

The target temperature in a kiln is determined entirely by the desired transformation of the material.

- If your primary focus is calcination (lime, gypsum): Your goal is to apply just enough heat to drive the chemical decomposition without sintering or "dead-burning" the material.

- If your primary focus is clinker production (cement): Your goal is to reach a specific sintering temperature to induce a partial melt and form new mineralogical phases.

- If your primary focus is purification or reduction (minerals): Your goal is to use temperature in combination with a controlled atmosphere to either burn off or chemically reduce specific unwanted elements.

Ultimately, temperature is the primary lever you pull to transform a low-value raw material into a high-value, specified final product.

Summary Table:

| Purpose | Temperature Range | Key Process |

|---|---|---|

| Calcination | >900°C (1650°F) | Chemical decomposition (e.g., limestone to lime) |

| Sintering | ~1450°C (2640°F) | Particle fusion (e.g., cement clinker formation) |

| Purification | Varies | Removal of volatiles and impurities |

Unlock Precision in High-Temperature Processing with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet unique experimental requirements. Whether you're focused on calcination, sintering, or purification, our tailored solutions ensure efficient material transformation and superior results.

Ready to enhance your operations? Contact us today to discuss how we can support your specific goals!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results

- How is bed depth controlled in a rotary kiln and why is it important? Optimize Heat Transfer and Efficiency

- What is the basic working principle of a rotary kiln? Master Industrial Thermal Processing Efficiency

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- What is an electric heating rotary kiln and what industries use it? Discover Precision Heating for High-Purity Materials