At their core, rotary kilns utilize advanced sealing technologies like hydraulic two-stage flap seals and graphite flexible seals. The primary benefit of these systems is to achieve a very low air leakage rate, which significantly enhances the kiln's thermal efficiency, reduces energy consumption, and lowers overall operational costs.

The crucial insight is that a rotary kiln's seal isn't just a component for containment; it's a critical control system. Effective sealing is fundamental to regulating the internal thermal and chemical environment, directly impacting process stability, energy efficiency, and profitability.

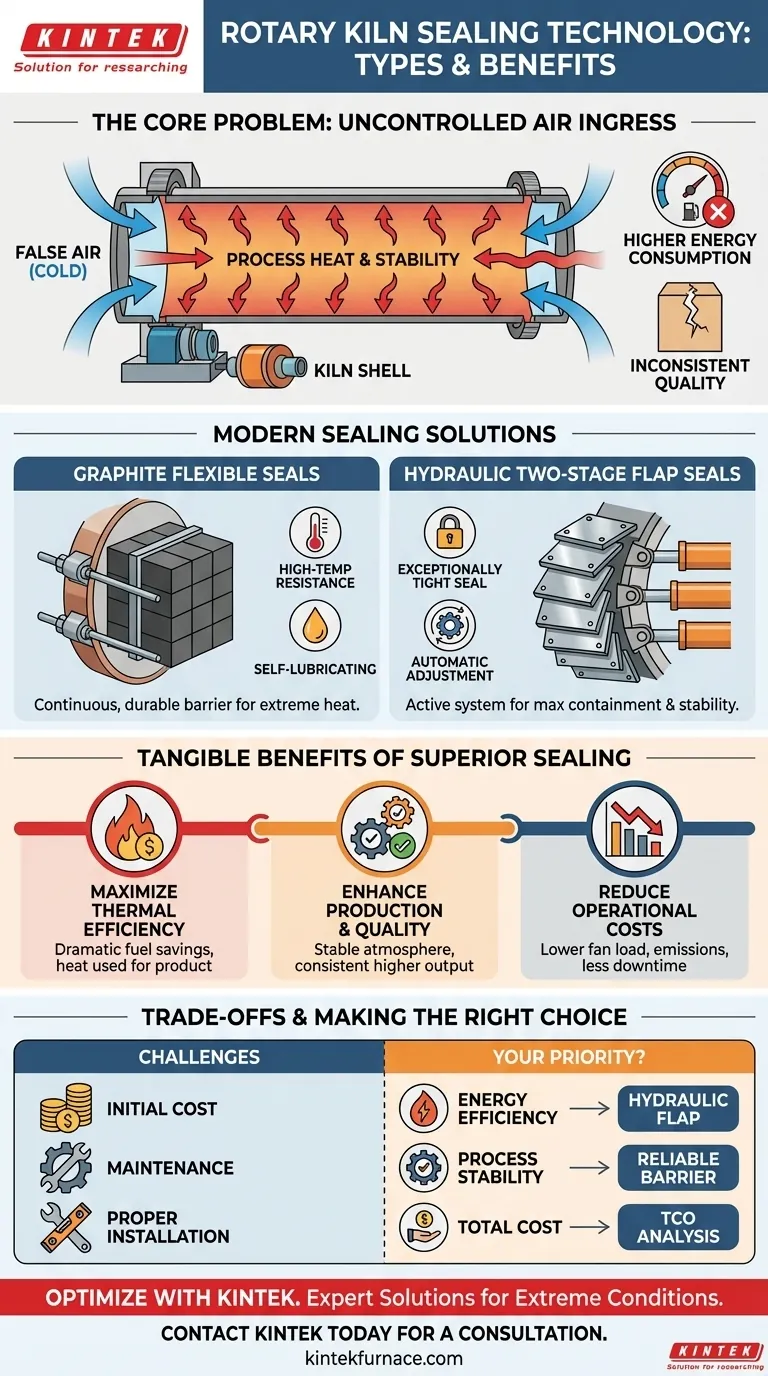

The Core Problem: Why Sealing is Critical in Rotary Kilns

A rotary kiln is designed to be a highly controlled thermal processing environment. The single biggest threat to this control is unwanted air entering the system, a problem that modern sealing technology is designed to solve.

The Challenge of Uncontrolled Air Ingress

This leakage, often called "false air" or "tramp air," is ambient-temperature air that gets drawn into the kiln at the feed and discharge ends. Because the kiln operates under a slight negative pressure, any gap becomes an entry point.

Impact on Thermal Dynamics

False air is cold and must be heated to the kiln's process temperature. This requires a significant amount of extra fuel, directly increasing energy consumption and operating costs for every cubic foot of air that leaks in.

Destabilizing the Process

Uncontrolled air ingress disrupts the kiln's delicate atmosphere. It can alter oxygen levels, affecting combustion efficiency and interfering with the specific chemical reactions required for the product, leading to inconsistent quality and reduced throughput.

A Closer Look at Modern Sealing Technologies

To combat the negative effects of air leakage, operators rely on sophisticated seals designed to accommodate the kiln's rotation and thermal expansion.

Graphite Flexible Seals

These seals use a series of graphite blocks or layers held under tension against the rotating kiln shell. Graphite is an ideal material because it can withstand extreme temperatures and is self-lubricating, providing a continuous and durable barrier.

Hydraulic Two-Stage Flap Seals

This is a more complex mechanical system that provides an exceptionally tight seal. It typically uses overlapping metal plates (flaps) pressed against the kiln shell with consistent force from a hydraulic system, which can automatically adjust for kiln movement or wear.

The Tangible Benefits of Superior Sealing

Investing in a high-performance sealing system translates directly into measurable operational improvements.

Maximizing Thermal Efficiency

The most immediate benefit is a dramatic reduction in fuel consumption. By preventing cold air from entering the system, all the energy from combustion is used to heat the product, not the leaking air.

Enhancing Production and Quality

A stable internal temperature and atmosphere, free from the fluctuations caused by air leakage, results in a more consistent and higher-quality final product. This also allows for higher production rates.

Reducing Operational Costs

Beyond direct fuel savings, effective seals can lower the load on system fans (as they move less air), reduce emissions, and create a more stable, predictable operation with less unscheduled downtime.

Understanding the Trade-offs and Challenges

While essential, implementing and maintaining high-performance seals requires careful consideration.

Initial Cost vs. Long-Term Savings

Advanced sealing systems represent a significant capital investment. This upfront cost must be weighed against the long-term, continuous savings in fuel and operational efficiency, which typically provide a rapid return on investment.

Maintenance and Durability

Seals are wear components operating in one of the harshest industrial environments imaginable—facing high temperatures, abrasion, and constant movement. They require regular inspection and maintenance to retain their effectiveness.

Proper Installation is Non-Negotiable

The performance of even the most advanced seal is entirely dependent on its installation. Improper alignment or incorrect tensioning will undermine its function and lead to premature failure.

Making the Right Choice for Your Operation

Selecting the appropriate sealing technology depends on your specific operational priorities.

- If your primary focus is maximizing energy efficiency: Prioritize advanced seals with the lowest documented air leakage rates, such as multi-layer graphite or hydraulic flap systems.

- If your primary focus is process stability and product quality: Choose a seal that provides a reliable and consistent barrier to maintain a stable internal atmosphere and temperature profile.

- If your primary focus is managing total operational costs: Conduct a total cost of ownership analysis that balances the seal's initial price against projected fuel savings and maintenance requirements.

Ultimately, investing in the right sealing technology transforms it from a simple component into a powerful tool for process control and profitability.

Summary Table:

| Sealing Technology | Key Benefit | Ideal For |

|---|---|---|

| Graphite Flexible Seals | Excellent high-temperature performance, self-lubricating | General high-heat applications, cost-effective durability |

| Hydraulic Two-Stage Flap Seals | Extremely low air leakage, automatic adjustment | Maximizing energy efficiency and process stability |

Ready to optimize your rotary kiln's performance and profitability?

The right sealing technology is a direct investment in lower fuel costs, higher product quality, and greater operational stability. Backed by expert R&D and manufacturing, KINTEK's sealing solutions are designed to withstand extreme conditions and deliver a rapid return on investment.

Let our experts help you select the perfect seal for your unique needs.

Contact KINTEL today for a consultation to discuss how our advanced sealing technology can transform your operation.

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are some drying applications of electromagnetic rotary kilns? Discover Efficient, Precise Drying Solutions

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results

- What is the basic working principle of a rotary kiln? Master Industrial Thermal Processing Efficiency