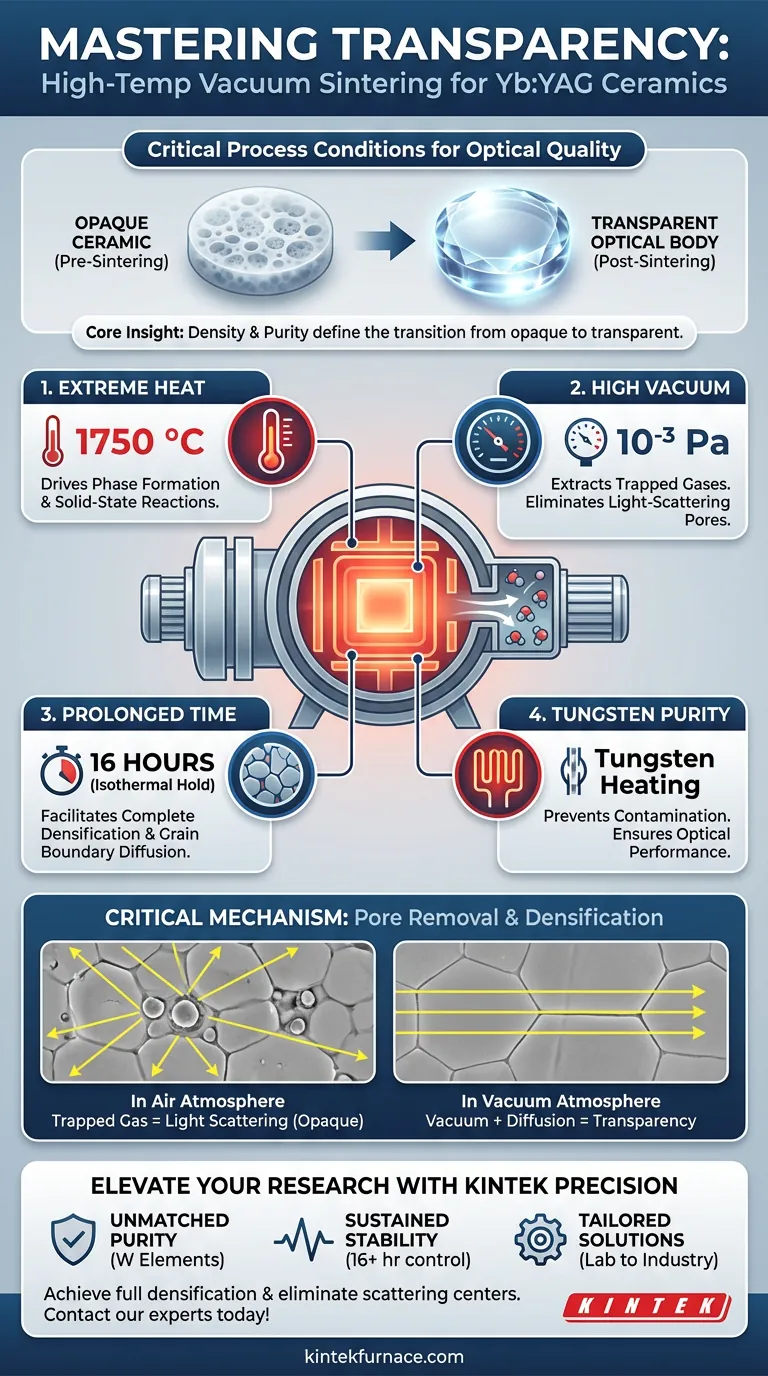

A high-temperature vacuum sintering furnace establishes a controlled environment defined by temperatures around 1750 °C and a high-vacuum atmosphere to synthesize Ytterbium-doped YAG (Yb:YAG) transparent ceramics. To ensure optical purity, these systems typically utilize tungsten heating elements and require prolonged isothermal heating durations, often extending to 16 hours, to facilitate complete densification.

Core Insight: The transition from an opaque ceramic to a transparent optical body relies entirely on density and purity. The vacuum furnace does not just heat the material; it creates a pressure-deficit environment that physically extracts residual gases from microscopic pores, eliminating the light-scattering centers that otherwise block transparency.

Precise Thermal Control for Phase Formation

Extreme Temperature Maintenance

To synthesize Yb:YAG ceramics, the furnace must provide and sustain extreme heat, specifically reaching temperatures of 1750 °C.

This thermal energy is necessary to drive the solid-state reactions required for the material to reach its correct crystallographic phase.

Prolonged Isothermal Heating

Reaching the target temperature is insufficient; the process requires a prolonged holding time, typically around 16 hours.

This extended duration ensures sufficient grain growth and allows time for the densification mechanisms to complete. It creates a uniform thermal field that drives the material toward a fully dense state.

The Role of Vacuum in Optical Quality

Eliminating Residual Gases

The most critical function of the furnace is the creation of a high-vacuum environment (often reaching levels of $10^{-3}$ Pa).

This vacuum actively removes residual gases trapped within the internal pores of the ceramic body. By lowering the internal pressure, the system prevents gas pockets from inhibiting the closure of pores.

Driving Grain Boundary Diffusion

Once gases are removed, the process relies on grain boundary diffusion to eliminate the pores entirely.

The combination of high heat and vacuum forces the grain boundaries to migrate, effectively "squeezing out" the void spaces. This results in an optically transparent body free of pore-related scattering centers.

Contamination Control via Tungsten

The primary reference highlights the specific use of tungsten heating elements within these furnaces.

Using tungsten rather than carbon or other materials is crucial to avoid impurity contamination. In doped ceramics like Yb:YAG, even trace impurities can degrade the optical performance and laser efficiency.

Critical Process Dynamics

The Necessity of Vacuum for Transparency

While standard oxide ceramics can be sintered in air to maintain stoichiometry, transparent ceramics require vacuum conditions.

In an air atmosphere, gas trapped inside closed pores cannot easily diffuse out, leaving behind microscopic voids. These voids scatter light, rendering the material opaque rather than transparent.

Balancing Time and Grain Growth

The 16-hour sinter time is a calculated trade-off.

While necessary for pore removal, excessive heating times can lead to abnormal grain growth, which may mechanically weaken the ceramic. The process conditions must be strictly monitored to balance densification with microstructural integrity.

Making the Right Choice for Your Goal

To optimize the preparation of Yb:YAG ceramics, align your furnace parameters with your specific quality metrics:

- If your primary focus is Optical Transparency: Prioritize the vacuum level and the isothermal holding time (16 hours) to ensure the complete removal of pore-related scattering centers.

- If your primary focus is Material Purity: Select a furnace equipped with tungsten heating elements and ensuring a clean vacuum environment to prevent impurity migration into the YAG lattice.

Summary: The successful synthesis of Yb:YAG transparent ceramics is defined by the synergy of 1750 °C heat, tungsten-protected purity, and deep vacuum to physically eliminate the microscopic pores that obstruct light.

Summary Table:

| Parameter | Process Requirement | Role in Synthesis |

|---|---|---|

| Sintering Temperature | 1750 °C | Drives solid-state reactions and phase formation |

| Atmosphere | High Vacuum ($10^{-3}$ Pa) | Extracts trapped gases to eliminate light-scattering pores |

| Heating Element | Tungsten | Prevents carbon contamination and ensures optical purity |

| Holding Time | 16 Hours | Facilitates grain boundary diffusion and full densification |

| Core Mechanism | Pore Removal | Transforms opaque ceramic into a transparent optical body |

Elevate Your Material Research with KINTEK Precision

Achieving the perfect optical transparency in Yb:YAG ceramics requires more than just heat; it demands the absolute control provided by KINTEK’s high-performance vacuum systems. Backed by expert R&D and manufacturing, we provide customizable Vacuum, Muffle, Tube, and CVD systems designed to meet the rigorous 1750 °C and high-vacuum demands of advanced ceramic synthesis.

Why choose KINTEK?

- Unmatched Purity: Options for tungsten heating to prevent contamination.

- Proven Stability: Sustained isothermal control for 16+ hour cycles.

- Tailored Solutions: Systems built specifically for lab and industrial high-temp needs.

Ready to eliminate scattering centers and achieve full densification? Contact our technical experts today to find the ideal furnace for your unique application!

Visual Guide

References

- Francesco Picelli, L. Esposito. Beyond Scanning Electron Microscopy: Comprehensive Pore Analysis in Transparent Ceramics Using Optical Microscopy. DOI: 10.3390/ceramics7010025

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the environmental advantages of vacuum-environment furnaces for coking? Learn how to eliminate leakage.

- How are vacuum furnaces constructed and operated? Unlock Precision and Purity in Material Processing

- How can rapid cooling (quenching) benefit the process in a vacuum furnace? Boost Efficiency and Material Properties

- What role does specialty insulation play in vacuum furnaces? Ensure Process Integrity and Efficiency

- How are parts cooled in vacuum carburizing, and what are the advantages? Achieve Superior Heat Treatment with Minimal Distortion

- What is the significance of thermocouple and furnace regulation synergy? Master High-Precision Vacuum Sintering

- What role does a laboratory vacuum annealing furnace play in ion-implanted ScN thin films? Restore Lattice Integrity

- What materials can be joined using vacuum brazing? Achieve High-Integrity Bonds for Dissimilar Metals and Ceramics