Precise synchronization between thermocouple monitoring and furnace regulation is the critical factor that aligns the actual thermal history of a niobium sample with its intended processing parameters. This synergy provides the direct feedback necessary to control heat treatment duration with extreme accuracy, ensuring the physical environment inside the vacuum furnace perfectly mirrors the required technical specifications.

The integration of real-time temperature data with furnace control systems enables the micro-management of oxygen impurity diffusion. This precise chemical tuning is essential for minimizing surface resistance and maximizing the electromagnetic performance of superconducting cavities.

The Mechanics of Thermal Precision

Closing the Feedback Loop

In high-temperature vacuum sintering, the thermocouple does not merely record data; it acts as the active driver for the furnace regulation system.

By providing direct temperature feedback, the system ensures that the actual thermal history of the niobium cavity matches the programmed recipe.

Exact Control of Treatment Duration

The synergy between these components allows for high-precision control over the heat treatment time.

This ensures the niobium is exposed to specific temperatures for exact durations, preventing under-processing or thermal overshoot.

Managing Oxygen Impurities

Regulating Diffusion Depth

The primary chemical objective of this synergy is the accurate regulation of oxygen impurity diffusion depth into the niobium surface layer.

As the furnace environment facilitates the thermal decomposition of the natural oxide layer (niobium pentoxide), oxygen diffuses into the niobium bulk.

The Role of Feedback

Without the tight coupling of monitoring and regulation, the depth of this diffusion cannot be finely tuned.

The feedback loop ensures that the diffusion process stops exactly when the optimal depth is reached, rather than relying on estimates.

Impact on Cavity Performance

Minimizing Surface Resistance

Precise control of oxygen diffusion is directly linked to the physical properties of the cavity surface.

By optimizing the impurity profile, the process minimizes the surface resistance of the niobium.

Eliminating High-Field Q-Slope

Proper regulation allows for the optimization of the quality factor (Q0) and the elimination of the high-field Q-slope (HFQS).

This results in a significant increase in the peak magnetic field capacity of the superconducting cavity.

Risks of Poor Synchronization

Divergent Thermal Histories

If the thermocouple and regulation system are not perfectly synced, the actual temperature profile will deviate from the intended parameters.

This discrepancy leads to unpredictable material properties, rendering the sintering process unrepeatable.

Compromised RF Performance

Failure to precisely control the diffusion depth leads to suboptimal oxygen distribution.

This results in higher surface resistance and a reduced ability for the cavity to sustain high magnetic fields, negating the benefits of the vacuum treatment.

Making the Right Choice for Your Goal

To maximize the performance of niobium superconducting cavities, the regulation strategy must be aligned with your specific performance metrics.

- If your primary focus is Surface Resistance: Ensure your feedback loop is calibrated to halt the process immediately upon reaching the optimal oxygen diffusion depth to minimize resistive losses.

- If your primary focus is Magnetic Field Capacity: Prioritize the stability of the regulation system to eliminate the high-field Q-slope (HFQS) through consistent thermal history.

Ultimate precision in temperature regulation is not just a process variable; it is the defining factor in achieving superior superconducting performance.

Summary Table:

| Feature | Significance in Sintering | Impact on Performance |

|---|---|---|

| Feedback Loop | Aligns actual thermal history with programmed recipe | Ensures process repeatability and material consistency |

| Duration Control | Prevents under-processing or thermal overshoot | Maintains structural integrity of the niobium cavity |

| Diffusion Tuning | Regulates oxygen impurity depth in the surface layer | Minimizes surface resistance and resistive losses |

| Q-Slope Mitigation | Eliminates high-field Q-slope (HFQS) | Maximizes peak magnetic field capacity and Q0 factor |

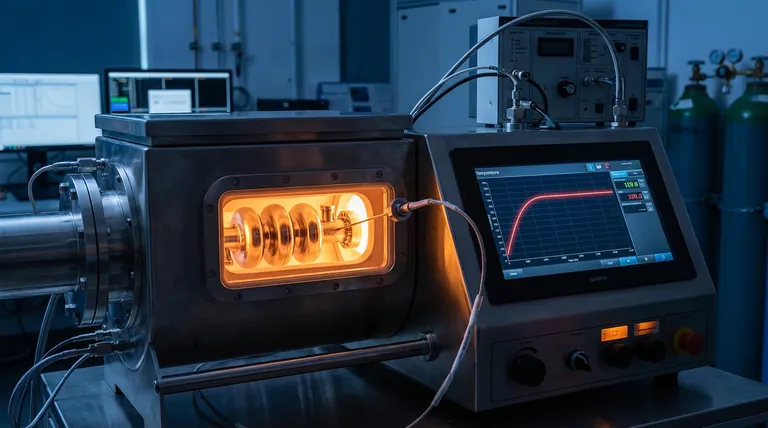

Elevate Your Superconducting Performance with KINTEK

Precision in high-temperature vacuum sintering is the defining factor for high-performance niobium cavities. At KINTEK, we understand that even a minor deviation in thermal history can compromise your results. Backed by expert R&D and world-class manufacturing, we provide high-precision Vacuum, CVD, Muffle, Tube, and Rotary systems designed to deliver the exact synchronization required for your most sensitive applications.

Whether you need to minimize surface resistance or eliminate high-field Q-slope, our lab furnaces are fully customizable to meet your unique technical specifications. Contact us today to optimize your heat treatment process and achieve superior material excellence.

References

- Eric Lechner, Charles Reece. Oxide dissolution and oxygen diffusion scenarios in niobium and implications on the Bean–Livingston barrier in superconducting cavities. DOI: 10.1063/5.0191234

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety