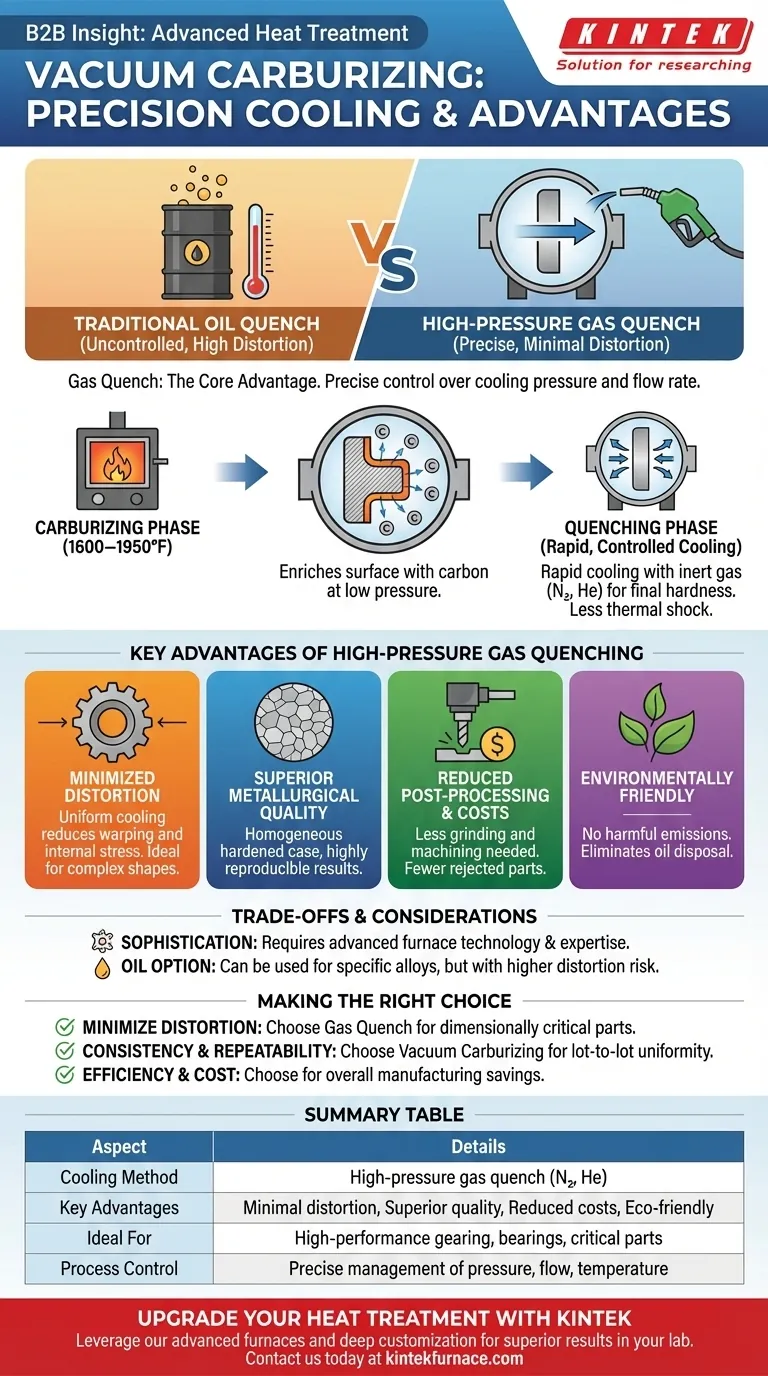

In vacuum carburizing, parts are cooled using a high-pressure gas quench instead of the traditional method of submerging them in oil. This process, also known as Low Pressure Carburizing (LPC), utilizes an inert gas like nitrogen or helium, where the pressure and flow rate can be precisely managed. This level of control is the primary reason this method offers significant advantages in producing high-quality, dimensionally stable components.

The core advantage of vacuum carburizing is not just the hardening process itself, but the shift from an uncontrolled oil quench to a precisely managed gas quench. This control directly translates into minimized part distortion, superior metallurgical consistency, and ultimately, lower overall production costs.

How the Process Delivers Superior Results

Vacuum carburizing is a two-stage process that first enriches the component's surface with carbon and then locks in the desired hardness through rapid cooling. The cooling stage is what truly sets it apart.

The Carburizing Phase

First, parts are heated in a vacuum chamber to temperatures between 1600–1950°F (870–1070°C). A hydrocarbon gas, such as acetylene, is introduced at a low pressure. The gas breaks down, allowing carbon to diffuse into the surface of the steel. This cycle is repeated to create a hardened "case" of a specific, controlled depth.

The Quenching Phase

Once the surface has the right amount of carbon, the part must be cooled rapidly to achieve its final hardness. Instead of a violent submersion in oil, a high-pressure gas is flooded into the chamber. The intensity of this quench is meticulously controlled by adjusting the gas pressure and velocity.

This controlled cooling is less of a thermal shock to the part, resulting in a more uniform and predictable transformation of the material's crystal structure.

Key Advantages of High-Pressure Gas Quenching

The decision to use gas instead of oil is deliberate and drives the most significant benefits of the vacuum carburizing process.

Unmatched Control Over Distortion

The primary benefit is the minimization and control of geometrical distortion. Plunging a hot part into liquid oil causes uneven and rapid cooling, which creates internal stresses that warp and deform the component.

A gas quench cools the part more uniformly. This is especially critical for complex or delicate shapes, ensuring the part remains within its specified tolerances after heat treatment.

Superior Metallurgical Quality

This process produces a homogeneous hardened case with exceptional consistency. Because the cooling rate is precisely managed, the results are highly reproducible from one part to the next and from one batch to another.

This reliability is why vacuum carburizing is a preferred method for high-performance applications like quality gearing and bearings.

Reduced Post-Processing and Costs

Because distortion is significantly reduced, the need for costly and time-consuming final grinding or machining is also lessened. Manufacturers can leave less "stock" material on surfaces, confident that the heat-treated part will be closer to its final dimensions.

Understanding the Trade-offs

While the benefits are substantial, it's important to understand the context in which this technology operates.

Process Sophistication

While modern systems are designed for ease of operation, achieving optimal results depends on sophisticated technology. The precise control of gas pressures, flow rates, and temperatures requires a state-of-the-art furnace and expert process management.

Oil vs. Gas Considerations

Although high-pressure gas quenching is the modern standard for minimizing distortion, some vacuum systems can still utilize an oil quench. Oil provides an extremely rapid quench rate which may be necessary for certain lower-hardenability steel alloys, but it comes at the cost of higher distortion risk. The choice depends on the material and the geometric complexity of the part.

Environmental and Safety Factors

A major, often overlooked advantage is that vacuum carburizing is an environmentally friendly and safe process. It produces no harmful emissions and eliminates the need for managing and disposing of large quantities of quench oil. This results in clean, dry parts and a safer, non-toxic working environment.

Making the Right Choice for Your Application

Selecting the right heat treatment method depends entirely on your final goal.

- If your primary focus is minimizing distortion and achieving tight tolerances: Vacuum carburizing with a high-pressure gas quench is the definitive choice for dimensionally critical parts.

- If your primary focus is process consistency and repeatability: The precise, data-driven control of vacuum carburizing delivers unmatched lot-to-lot uniformity for high-performance components.

- If your primary focus is manufacturing efficiency and cost reduction: The reduction in post-treatment grinding and machining can lead to significant overall cost savings, despite the advanced technology involved.

Ultimately, vacuum carburizing with gas quenching elevates heat treatment from a conventional thermal process to a precise engineering step for creating superior components.

Summary Table:

| Aspect | Details |

|---|---|

| Cooling Method | High-pressure gas quench (e.g., nitrogen, helium) |

| Key Advantages | Minimal distortion, superior metallurgical consistency, reduced post-processing, environmental safety |

| Ideal For | High-performance applications like gearing and bearings, dimensionally critical parts |

| Process Control | Precise management of gas pressure, flow rate, and temperature for uniform results |

Upgrade Your Heat Treatment Process with KINTEK's Advanced Solutions

Are you aiming to minimize distortion, enhance metallurgical quality, and reduce costs in your laboratory? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by strong deep customization capabilities to precisely meet your unique experimental requirements.

Contact us today to discuss how our tailored vacuum carburizing systems can deliver superior results for your high-performance components!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion