At its core, a box-type atmosphere furnace relies on two primary features to control its internal environment: a fully sealed furnace body and a tightly sealed door. These elements work in concert with integrated gas inlet and outlet systems to prevent external air from contaminating the process and to stop the controlled atmosphere from leaking out.

The quality of a furnace's seal is the fundamental distinction between a standard high-temperature oven and a true atmosphere furnace. This sealing system is not just a feature but the core technology that enables precise, repeatable control over sensitive material processing.

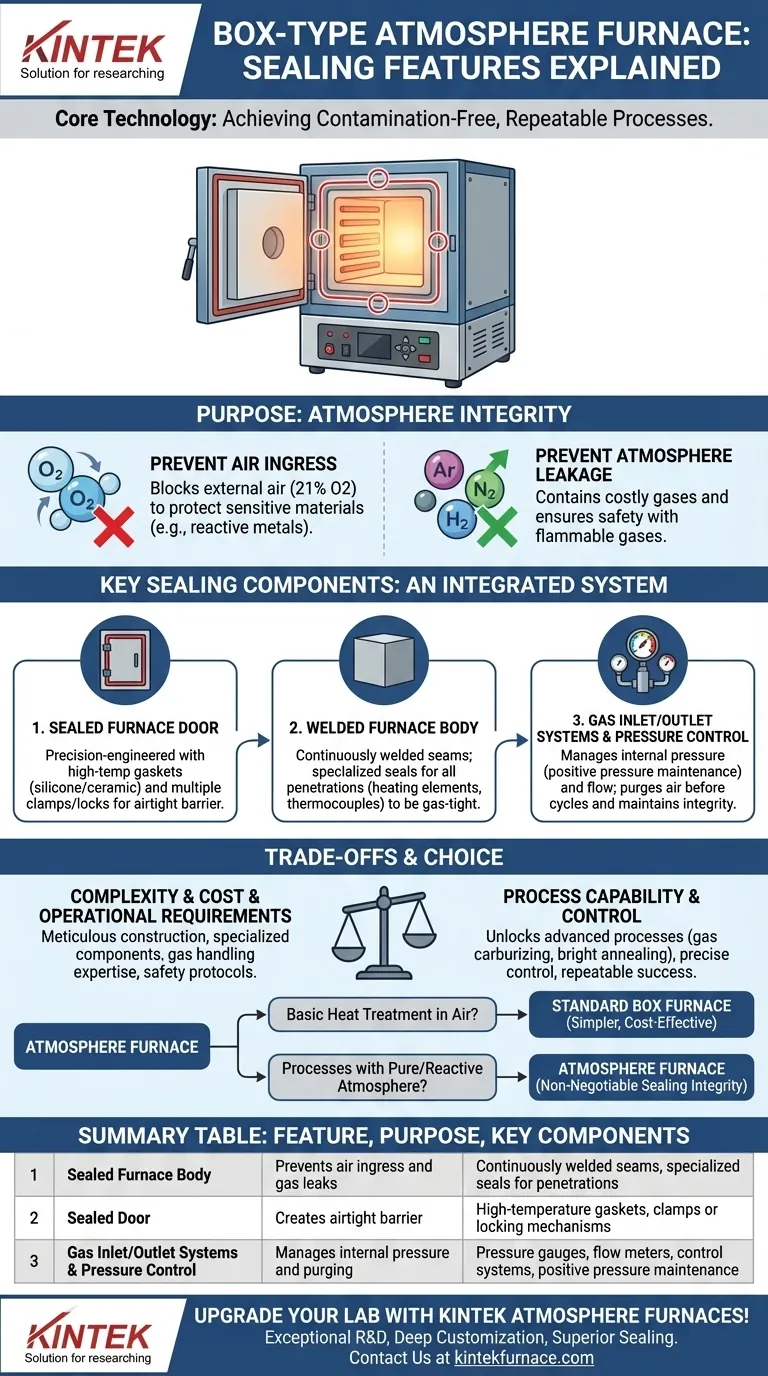

The Purpose of Sealing: Atmosphere Integrity

The entire value of an atmosphere furnace comes from its ability to maintain a specific, artificially created gas environment. The sealing system is the primary enabler of this capability.

Preventing Air Ingress

Many advanced heat treatment processes, such as bright annealing or sintering of reactive metals, can be ruined by the presence of oxygen.

A robust seal ensures that external air, which is approximately 21% oxygen, cannot enter the chamber and react with the materials being processed. This is crucial for achieving specific metallurgical properties and surface finishes.

Preventing Atmosphere Leakage

Atmosphere furnaces are often filled with expensive or specialized gases like argon, nitrogen, or hydrogen. A tight seal prevents these costly gases from escaping, reducing operational expenses.

Furthermore, if the process uses flammable or explosive gases like hydrogen, a perfect seal is a critical safety measure to prevent hazardous gas from leaking into the surrounding workspace.

Key Components of the Sealing System

A true atmosphere furnace seal is an integrated system, not just a single part. It involves multiple components designed to work together to create a contained environment.

The Sealed Furnace Door

Unlike a standard box furnace with a simple door, an atmosphere furnace door is a precision-engineered component. It typically features high-temperature silicone or ceramic fiber gaskets seated in a groove.

Multiple clamps or a locking mechanism apply even pressure around the entire door perimeter to compress the gasket, creating an airtight barrier against the furnace frame.

The Welded Furnace Body

The chamber of an atmosphere furnace is constructed to be a monolithic, sealed vessel. This means all seams are continuously welded to be gas-tight.

Any necessary penetrations through the furnace body—for heating elements, thermocouples, or gas lines—are also fitted with specialized seals or welded flanges to prevent leaks.

Gas Inlet and Outlet Systems

These are more than just simple ports. The gas system is integral to maintaining the seal's effectiveness by managing internal pressure.

The system allows the chamber to be purged of air before a cycle and then maintains a slight positive pressure during operation. This positive pressure is the ultimate defense, ensuring that if a minuscule leak were to exist, gas would flow out rather than air flowing in.

Pressure and Flow Control

Modern atmosphere furnaces include pressure gauges, flow meters, and control systems. These instruments monitor the internal environment in real time, adjusting gas flow to maintain the target pressure. This ensures the integrity of the atmosphere throughout the entire heat treatment cycle.

Understanding the Trade-offs

The decision to use an atmosphere furnace comes with clear trade-offs directly related to its sophisticated sealing system.

Complexity and Cost

The meticulous construction required for a gas-tight seal makes atmosphere furnaces significantly more complex and expensive to manufacture than standard box furnaces. The precision-welded body, engineered door, and integrated gas control systems all add to the cost.

Process Capability

This is the benefit that justifies the cost. The ability to control the atmosphere unlocks a wide range of advanced processes like gas carburizing, carbonitriding, and bright quenching. These treatments are impossible to perform in a standard furnace that allows air interaction.

Operational and Safety Requirements

Operating an atmosphere furnace demands more expertise. It involves managing potentially flammable and explosive gases, requiring trained operators, gas monitoring systems, and strict safety protocols. A standard box furnace, by contrast, requires only basic high-temperature safety awareness.

Making the Right Choice for Your Application

Understanding the role of sealing allows you to select the correct tool for your specific goal.

- If your primary focus is basic heat treatment in air (e.g., tempering, standard annealing, ceramic firing): A standard box furnace is a more cost-effective and simpler solution.

- If your primary focus is processes requiring a pure, oxygen-free environment (e.g., bright annealing, sintering reactive metals): A true atmosphere furnace with a verified, high-integrity sealing system is non-negotiable for achieving quality results.

- If your primary focus is processes that add elements to a material (e.g., gas carburizing): You must use an atmosphere furnace, as the sealing is what contains the reactive gas needed for the surface treatment.

Ultimately, investing in a furnace with the right sealing system is an investment in process control and repeatable success.

Summary Table:

| Feature | Purpose | Key Components |

|---|---|---|

| Sealed Furnace Body | Prevents air ingress and gas leaks | Continuously welded seams, specialized seals for penetrations |

| Sealed Door | Creates airtight barrier | High-temperature gaskets, clamps or locking mechanisms |

| Gas Inlet/Outlet Systems | Manages internal pressure and purging | Pressure gauges, flow meters, control systems |

| Pressure Control | Ensures atmosphere integrity | Real-time monitoring, positive pressure maintenance |

Upgrade your lab's capabilities with KINTEK's advanced atmosphere furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise matching to your unique experimental needs, delivering superior sealing for contamination-free processes. Don't let leaks compromise your results—contact us today to discuss how our furnaces can enhance your precision and efficiency!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process