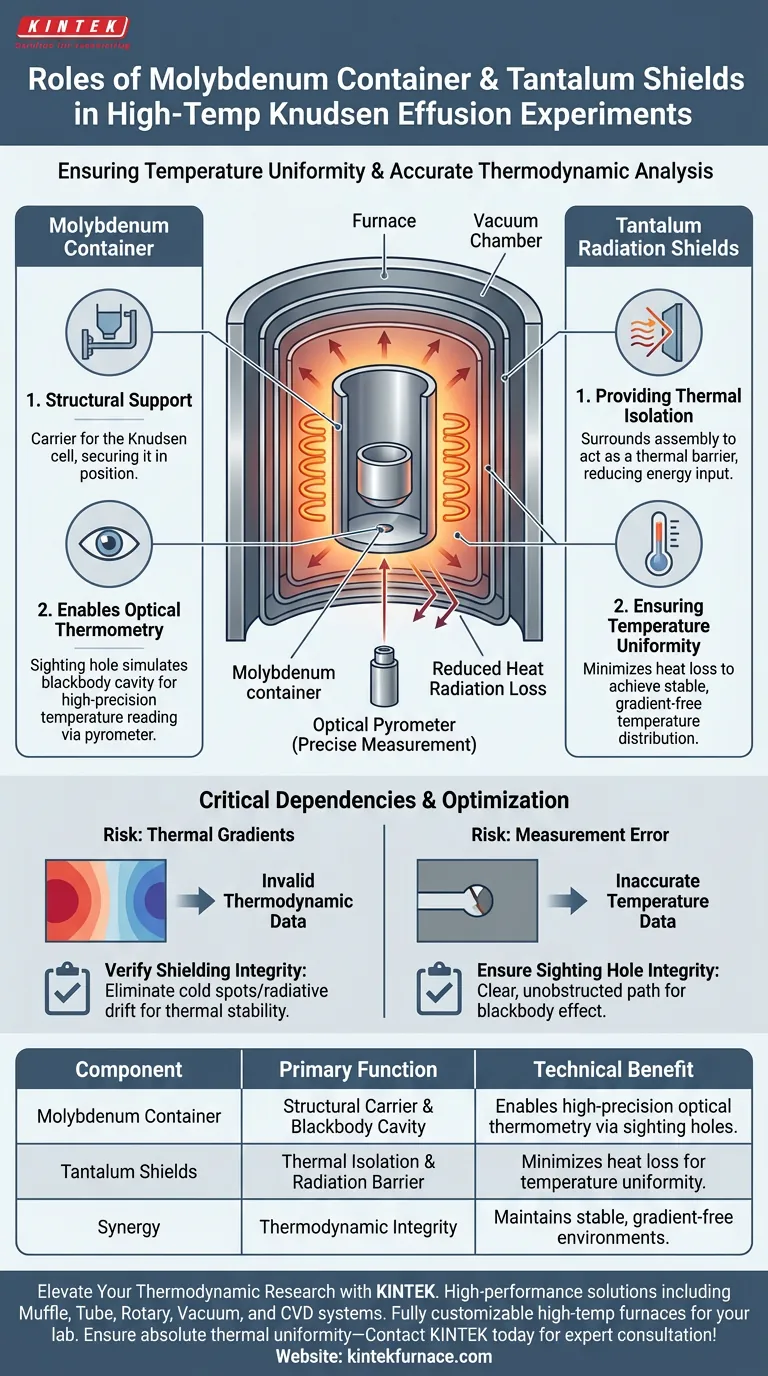

In high-temperature Knudsen effusion experiments, the Molybdenum container and Tantalum radiation shields serve as the primary mechanisms for structural support, temperature measurement, and thermal isolation. The Molybdenum container acts as the physical carrier for the cell and enables optical thermometry, while the Tantalum shields surround the assembly to minimize heat loss. Together, these components maintain the strict thermal conditions required for accurate thermodynamic analysis.

The reliability of thermodynamic constants derived from these experiments depends entirely on temperature uniformity. The Molybdenum container facilitates precise measurement via blackbody simulation, while the Tantalum radiation shields preserve the thermal stability necessary for those measurements to remain valid.

The Role of the Molybdenum Container

The Molybdenum container functions as more than a simple vessel; it is integral to the metrology of the experiment.

Structural Support

Its primary physical function is to act as a carrier for the Knudsen cell. It secures the cell within the heating assembly, ensuring it remains positioned correctly throughout the high-temperature process.

Enabling Optical Thermometry

The container is engineered with a specific sighting hole at the bottom.

This feature is critical because it simulates a blackbody cavity. By creating this cavity, the container allows an optical pyrometer to read the temperature with high precision, bypassing the errors often associated with surface emissivity issues.

The Role of Tantalum Radiation Shields

While the container aids in measurement, the Tantalum shields are responsible for maintaining the environment's integrity.

Providing Thermal Isolation

High-temperature experiments are prone to rapid energy dissipation. The Tantalum shields surround the heating assembly to act as a thermal barrier.

Their specific role is to reduce heat radiation loss. Without this shielding, the energy input required to maintain temperature would be excessive and difficult to control.

Ensuring Temperature Uniformity

The ultimate goal of minimizing radiation loss is to achieve a stable temperature distribution within the Knudsen cell.

Any fluctuation or gradient in temperature directly impacts the calculated thermodynamic constants. The shields ensure the entire cell remains at the target temperature, rather than just the heating element.

Critical Dependencies and Trade-offs

Understanding the relationship between these components is vital for avoiding experimental errors.

The Risk of Thermal Gradients

If the Tantalum shields are compromised or positioned incorrectly, radiation loss will become non-uniform.

This leads to thermal gradients across the cell. Even if the optical pyrometer reads the correct temperature at the sighting hole, other parts of the sample may be at different temperatures, rendering the derived thermodynamic data invalid.

Measurement Dependency

The Molybdenum container's utility is strictly tied to the integrity of the sighting hole.

If this hole is obstructed or misaligned with the pyrometer, the blackbody simulation fails. The resulting temperature data will be inaccurate, regardless of how stable the Tantalum shields keep the actual environment.

Optimizing Experimental Accuracy

To ensure valid results in your Knudsen effusion studies, consider the distinct functions of these components during setup.

- If your primary focus is precise data acquisition: Ensure the Molybdenum container’s sighting hole provides a clear, unobstructed path for the optical pyrometer to utilize the blackbody effect.

- If your primary focus is thermal stability: Verify that the Tantalum radiation shields fully encapsulate the heating assembly to eliminate cold spots or radiative drift.

By strictly maintaining the integrity of these containment and shielding elements, you ensure the reliability of the temperature-sensitive constants derived from your research.

Summary Table:

| Component | Primary Function | Technical Benefit |

|---|---|---|

| Molybdenum Container | Structural Carrier & Blackbody Cavity | Enables high-precision optical thermometry via sighting holes. |

| Tantalum Shields | Thermal Isolation & Radiation Barrier | Minimizes heat loss to ensure temperature uniformity across the cell. |

| Synergy | Thermodynamic Integrity | Maintains stable, gradient-free environments for accurate data derivation. |

Elevate Your Thermodynamic Research with KINTEK

Precision in high-temperature experiments starts with superior materials. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized components for Knudsen effusion setups. Our lab high-temp furnaces are fully customizable to meet your unique experimental needs.

Ensure absolute thermal uniformity in your lab—Contact KINTEK today for expert consultation!

Visual Guide

References

- Alexander Halwax, Johannes Schenk. Enthalpy of Formation of Calcium and Magnesium Oxide Obtained by Knudsen Effusion Mass Spectrometry. DOI: 10.1007/s11663-024-02995-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Which heating element is most effective? The definitive guide to choosing the right material for your application.

- What are the operational characteristics of MoSi2 heating elements? Achieve High-Temp Precision and Longevity

- How do Type-S thermocouples contribute to monitoring temperature fields in niobium furnaces for precise heat treatment?

- What are resistance heating elements made of and where are they used? Discover Materials for Efficient Heat Generation

- What is the service life of MoSi2 heating elements and how do they perform in chemical environments? Maximize Longevity with Proper Use

- What is a molybdenum disilicide heating element and what are its key characteristics? Discover High-Temp Excellence

- Why is a flow reaction chamber with an integrated heater necessary? Decoupling Thermal and Plasmonic Effects

- Why is a furnace system equipped with multiple thermocouples necessary for tungsten testing? Achieve Thermal Precision