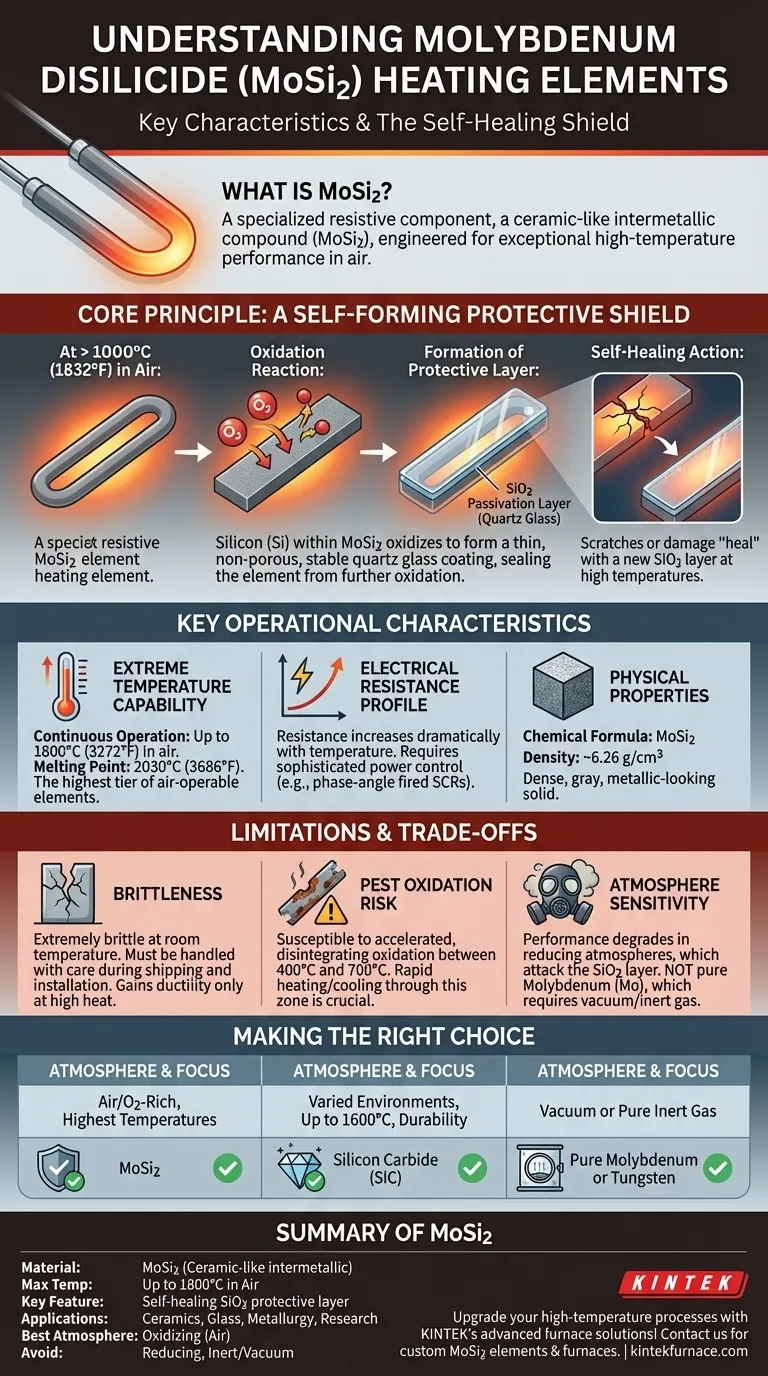

In short, a molybdenum disilicide (MoSi2) heating element is a specialized resistive component made from a ceramic-like intermetallic compound. It is engineered for exceptional performance in high-temperature industrial furnaces operating in air, capable of reaching temperatures that would destroy most conventional metal elements. Its defining characteristic is its ability to form a protective glass-like layer on its surface, which prevents it from burning up in an oxidizing atmosphere.

The crucial insight is that MoSi2 doesn't just resist heat; it uses the high-temperature, oxidizing environment to create its own self-healing, protective shield. This unique mechanism is what allows it to achieve an exceptionally long service life at extreme temperatures where other materials fail.

The Core Principle: A Self-Forming Protective Shield

How Oxidation Becomes a Strength

At temperatures above approximately 1000°C, a molybdenum disilicide element begins to react with oxygen in the air.

Instead of destructively burning, the silicon (Si) within the MoSi2 compound oxidizes to form a thin, non-porous, and highly stable passivation layer of silicon dioxide (SiO2)—essentially a quartz glass coating.

This glassy layer seals the underlying element material from further contact with oxygen, effectively stopping the oxidation process and allowing the element to operate stably for thousands of hours.

Self-Healing in Action

If this protective layer is ever scratched or damaged while at operating temperature, the exposed MoSi2 material will immediately react with the surrounding air to "heal" the breach with a new layer of SiO2. This gives the elements remarkable durability in harsh furnace environments.

Key Operational Characteristics

Extreme Temperature Capability

MoSi2 elements are designed for continuous operation at furnace temperatures up to 1800°C (3272°F), placing them in the highest tier of air-operable heating elements. The material itself has a melting point of 2030°C (3686°F), providing a significant safety margin.

Electrical Resistance Profile

The electrical resistance of a MoSi2 element increases dramatically as its temperature rises. This property requires a sophisticated power control system, typically using phase-angle fired SCRs (Silicon Controlled Rectifiers), to precisely manage the power output as the furnace heats up and cools down.

Physical and Chemical Properties

The chemical formula for the compound is MoSi2. It is a dense, gray, metallic-looking solid with a density of approximately 6.26 g/cm³. It is primarily used for heating applications in ceramics, glass manufacturing, metallurgy, and materials research.

Understanding the Trade-offs and Limitations

Brittleness at Room Temperature

Like many ceramics, MoSi2 elements are very brittle and fragile at room temperature. They must be handled with extreme care during shipping, storage, and installation to prevent cracking or fracture. They only gain ductility at very high temperatures.

"Pest" Oxidation Risk

In a mid-range temperature band, typically 400°C to 700°C, MoSi2 can be susceptible to a phenomenon known as pest oxidation. This is a form of accelerated, disintegrating oxidation that can occur if the element is held in this temperature range for extended periods. For this reason, furnaces using these elements should be heated and cooled rapidly through this zone.

Atmosphere Sensitivity

While unparalleled in oxidizing atmospheres like air, MoSi2 performance can be degraded by certain chemical environments. Reducing atmospheres, in particular, can attack and strip away the protective SiO2 layer, leading to rapid element failure.

MoSi2 vs. Pure Molybdenum: A Critical Distinction

It is vital not to confuse molybdenum disilicide (MoSi2) elements with those made of pure molybdenum (Mo). Pure molybdenum is a refractory metal that oxidizes catastrophically in air at high temperatures and must be operated in a vacuum or a protective, inert atmosphere. MoSi2 is specifically designed for operation in air.

Making the Right Choice for Your Application

Choosing the right heating element requires matching the material's properties to the specific thermal process and atmosphere.

- If your primary focus is achieving the highest possible temperatures in an air or oxygen-rich atmosphere: MoSi2 is the premier choice, offering stability and long life where other elements cannot survive.

- If your primary focus is robust performance at slightly lower temperatures (up to 1600°C) or in more chemically varied environments: A silicon carbide (SiC) element may offer a more durable and cost-effective solution.

- If your primary focus is heating within a vacuum or a pure, inert gas atmosphere: A refractory metal element, such as pure molybdenum or tungsten, is the correct technical choice.

Ultimately, selecting the correct element is about understanding the unique chemistry of your high-temperature environment.

Summary Table:

| Characteristic | Details |

|---|---|

| Material | Molybdenum disilicide (MoSi2), a ceramic-like intermetallic compound |

| Max Operating Temp | Up to 1800°C (3272°F) in air |

| Key Feature | Forms a self-healing SiO2 protective layer at high temperatures |

| Applications | Ceramics, glass manufacturing, metallurgy, materials research |

| Limitations | Brittle at room temperature, susceptible to pest oxidation at 400-700°C |

| Atmosphere Suitability | Best for oxidizing atmospheres like air; not for reducing or inert/vacuum |

Upgrade your high-temperature processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable MoSi2 heating elements and custom high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and durability. Contact us today to discuss how we can support your specific applications and deliver superior performance!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes