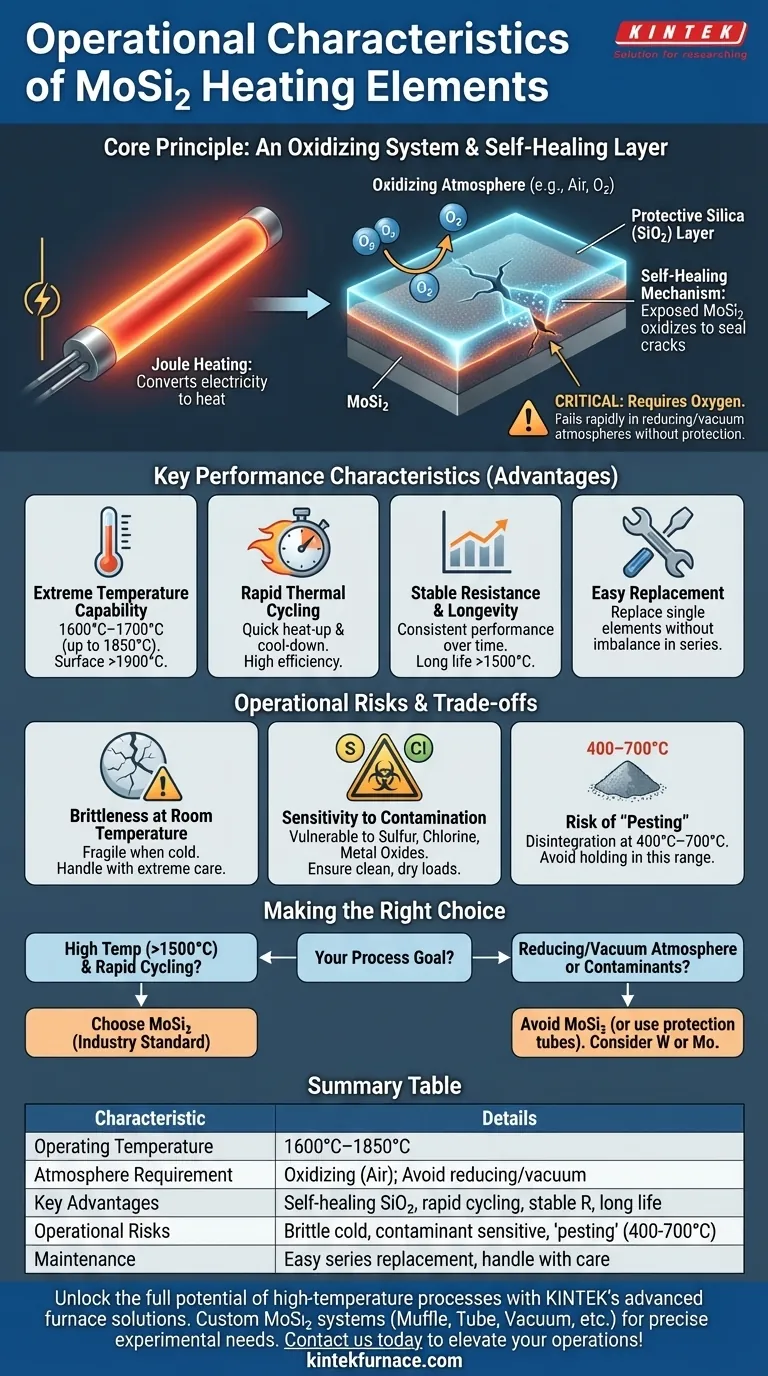

In short, Molybdenum Disilicide (MoSi₂) heating elements are defined by their ability to achieve exceptionally high operating temperatures in industrial and laboratory furnaces. They function by converting electrical energy into heat, but their unique performance and longevity are entirely dependent on forming a protective, self-healing glass layer in the presence of oxygen.

While their extreme temperature capability is the main draw, the true operational advantage of MoSi₂ lies in its self-healing silica layer. This mechanism grants them long life in oxygen-rich environments but also makes them uniquely vulnerable to specific contaminants and operational errors.

The Core Principle: An Oxidizing System

MoSi₂ elements are more than simple resistors; they are part of a dynamic system that relies on a specific chemical reaction to survive at high temperatures.

How MoSi₂ Generates Heat

At its most basic level, a MoSi₂ element operates on the principle of Joule heating. Electrical current is passed through the resistive material, which converts the electrical energy into thermal energy.

Higher current results in a higher temperature. However, every element has a maximum current and power density limit that cannot be exceeded without causing rapid failure.

The Protective Silica (SiO₂) Layer

The key to MoSi₂'s performance is what happens when it's heated in an atmosphere containing oxygen. The molybdenum disilicide on the surface oxidizes to form a thin, non-conductive layer of quartz glass (silica, SiO₂).

This layer is self-healing. If a crack or flaw develops, the exposed MoSi₂ underneath immediately oxidizes to repair the protective barrier. This is the source of the element's "antioxidant" and "auto-repair" properties.

The Critical Need for Oxygen

This protective mechanism means MoSi₂ elements are specifically designed for continuous operation in an oxidizing atmosphere like air.

Without sufficient oxygen, the silica layer cannot form or be maintained. Using these elements in reducing atmospheres (like hydrogen or cracked ammonia) or a hard vacuum will lead to rapid degradation and failure unless they are housed in special protection tubes.

Key Performance Characteristics

Understanding the core principle reveals why MoSi₂ elements exhibit their well-known operational traits.

Extreme Temperature Capability

MoSi₂ elements are the standard for applications requiring the highest process temperatures.

Furnace working temperatures typically range from 1600°C to 1700°C (2912°F to 3092°F), with some grades allowing for temperatures up to 1850°C. The surface of the element itself can reach over 1900°C.

Rapid Thermal Cycling

The elements have excellent thermal responsiveness. Their ability to heat up and cool down quickly improves process efficiency and allows for faster cycle times compared to many other element types.

Stable Resistance and Longevity

Unlike some heating elements that "age" and increase in resistance over time, MoSi₂ maintains a relatively stable resistance throughout its service life. This simplifies power control system design.

This stability, combined with the self-healing silica layer, gives the elements a very long lifespan, especially when operated continuously at temperatures above 1500°C.

Ease of Replacement

The stable resistance allows new elements to be wired in series with older ones without causing power imbalances. This significantly simplifies maintenance, as a single failed element can be replaced without needing to replace the entire set.

Understanding the Trade-offs and Operational Risks

The high performance of MoSi₂ elements comes with specific operational requirements and vulnerabilities that must be respected.

Brittleness at Room Temperature

Like many ceramic materials, MoSi₂ elements are strong at high temperatures but brittle and fragile when cold. They must be handled with extreme care during shipping, installation, and furnace maintenance to avoid mechanical shock or fracture.

Sensitivity to Contamination

The protective silica layer can be destroyed by chemical reactions with certain contaminants. This is the single greatest cause of premature element failure.

Substances like sulfur, chlorine, and certain metal oxides (often found in colorants for zirconia) can attack the SiO₂ layer, leading to catastrophic oxidation. Proper drying of all materials placed in the furnace is critical.

Risk of "Pesting" at Low Temperatures

Between approximately 400°C and 700°C, MoSi₂ can be subject to an accelerated form of oxidation known as "pesting." In this temperature range, the material can disintegrate into a powder.

This is why it is recommended to heat through this temperature band as quickly as possible and avoid holding the furnace in this range for extended periods.

Making the Right Choice for Your Application

Selecting the right heating element requires matching its characteristics to your process goals.

- If your primary focus is reaching process temperatures above 1500°C: MoSi₂ is the industry standard and the most reliable choice for long-term stability in this range.

- If your process requires rapid heating and cooling cycles: The excellent thermal responsiveness of MoSi₂ makes it ideal for applications needing quick turnarounds.

- If your furnace atmosphere is reducing or a vacuum: MoSi₂ is unsuitable unless you can use specialized, costly protection tubes. Look to elements like tungsten or pure molybdenum instead.

- If your process involves potential chemical contaminants: You must commit to strict furnace cleaning and material drying protocols to prevent the premature chemical attack of MoSi₂ elements.

Understanding these operational principles allows you to harness the full potential of MoSi₂ elements, ensuring both process efficiency and maximum equipment lifespan.

Summary Table:

| Characteristic | Details |

|---|---|

| Operating Temperature | 1600°C to 1700°C (up to 1850°C for some grades) |

| Atmosphere Requirement | Oxidizing (e.g., air); avoid reducing atmospheres and vacuum |

| Key Advantages | Self-healing silica layer, rapid thermal cycling, stable resistance, long lifespan |

| Operational Risks | Brittleness at room temperature, sensitivity to contaminants (e.g., sulfur, chlorine), risk of 'pesting' at 400-700°C |

| Maintenance | Easy replacement in series, handle with care when cold |

Unlock the full potential of high-temperature processes with KINTEK's advanced furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with MoSi2-equipped systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and lifespan. Contact us today to discuss how we can elevate your operations!

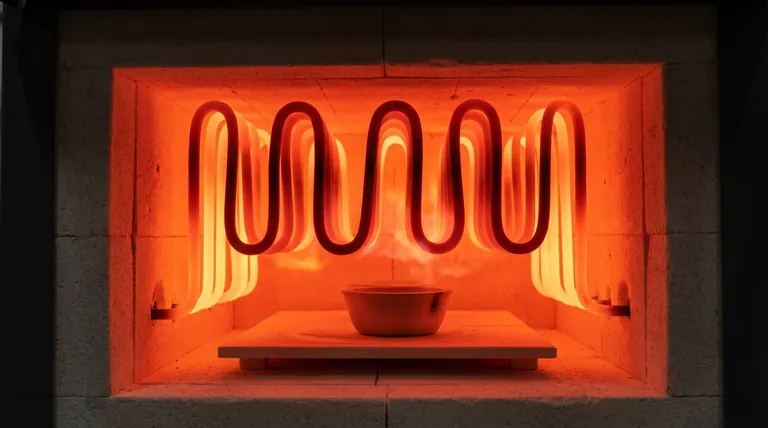

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability