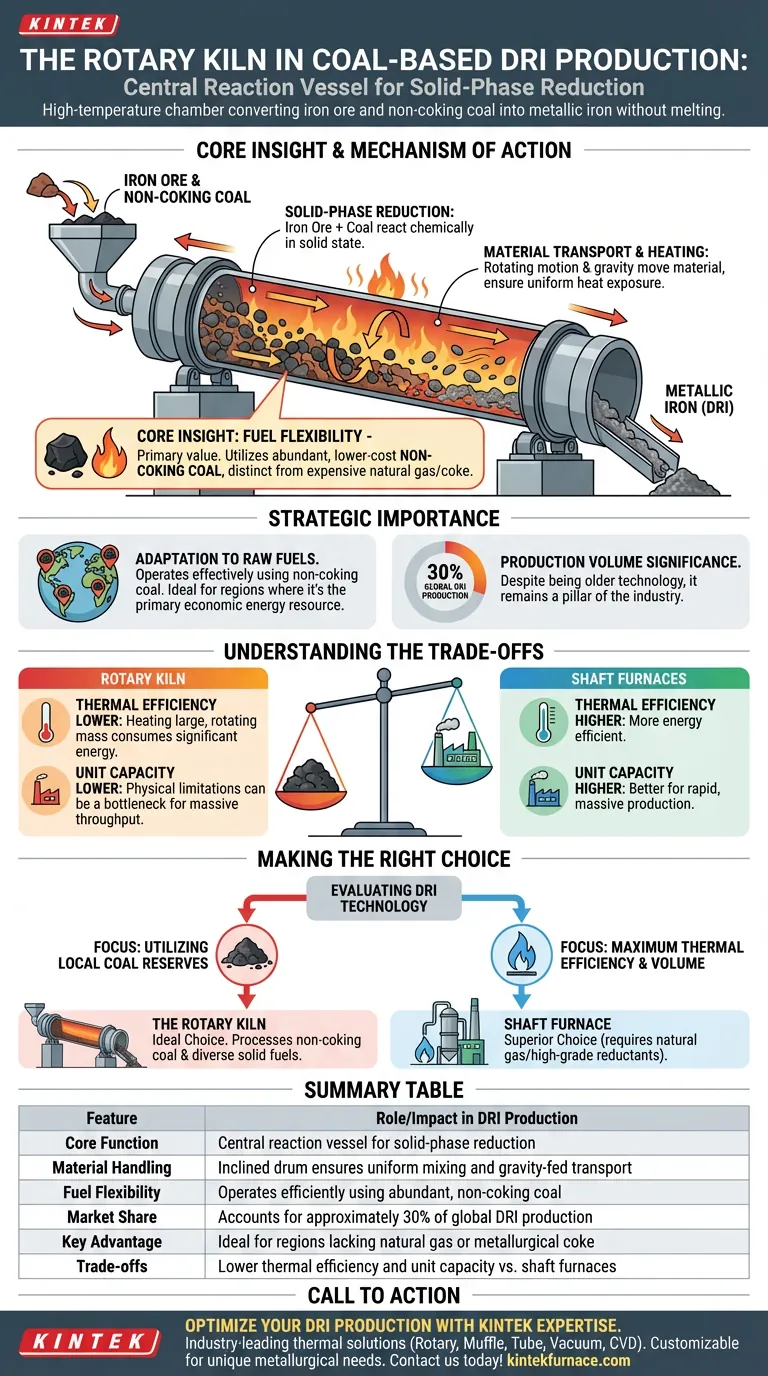

The rotary kiln serves as the central reaction vessel in coal-based Direct Reduced Iron (DRI) production. It functions as a high-temperature chamber where iron ore and non-coking coal are mixed to undergo solid-phase reduction, chemically converting the ore into metallic iron without melting it.

Core Insight: The rotary kiln's primary value lies in its fuel flexibility. While it generally has lower thermal efficiency and capacity compared to shaft furnaces, it remains essential for approximately 30% of the market because it allows producers to utilize abundant, lower-cost non-coking coal rather than expensive natural gas or metallurgical coke.

The Mechanism of Action

Solid-Phase Reduction

The primary biological or chemical function of the kiln is to facilitate solid-phase reduction. Inside the vessel, iron ore and coal react chemically while remaining in a solid state.

The rotating motion ensures that the coal (reductant) and iron ore are thoroughly mixed. This constant tumbling exposure allows carbon from the coal to strip oxygen from the iron ore, producing metallic iron.

Material Transport and Heating

Physically, the kiln is a large, cylindrical drum that is slightly inclined. As the drum rotates, gravity and friction work together to gradually move the material from the input end to the discharge end.

This design eliminates the need for internal conveyors. It ensures the raw materials are exposed to uniform heat throughout the journey, which is critical for maintaining a consistent chemical reaction.

Strategic Importance in Coal-Based DRI

Adaptation to Raw Fuels

The most significant advantage of the rotary kiln in this context is its adaptability to diverse raw fuels.

Unlike blast furnaces or gas-based shaft furnaces that often require high-grade coke or natural gas, the rotary kiln operates effectively using non-coking coal. This makes it the technology of choice in regions where non-coking coal is the primary or most economic energy resource.

Production Volume Significance

Despite being an older technology compared to some modern gas-based methods, the rotary kiln remains a pillar of the industry. It accounts for roughly 30% of global DRI production, underscoring its relevance in specific geographic and economic contexts.

Understanding the Trade-offs

Thermal Efficiency

While versatile, the rotary kiln operates with lower thermal efficiency than shaft furnaces. The nature of heating a large, rotating mass of solids consumes significant energy relative to the output produced.

Unit Capacity Limitations

The scale of production is also a constraint. Rotary kilns generally offer lower unit capacity compared to shaft furnaces. For operations requiring massive, rapid throughput, the physical limitations of the rotating drum can become a bottleneck.

Making the Right Choice for Your Goal

If you are evaluating DRI production technologies, the decision largely depends on your available energy resources and production scale.

- If your primary focus is utilizing local coal reserves: The rotary kiln is the ideal choice due to its ability to process non-coking coal and diverse solid fuels effectively.

- If your primary focus is maximum thermal efficiency and volume: A shaft furnace is likely superior, provided you have access to the necessary natural gas or high-grade reductants.

The rotary kiln remains a vital tool for converting low-cost solid fuels into valuable iron units where other methods are economically unfeasible.

Summary Table:

| Feature | Role/Impact in DRI Production |

|---|---|

| Core Function | Central reaction vessel for solid-phase reduction |

| Material Handling | Inclined drum ensures uniform mixing and gravity-fed transport |

| Fuel Flexibility | Operates efficiently using abundant, non-coking coal |

| Market Share | Accounts for approximately 30% of global DRI production |

| Key Advantage | Ideal for regions lacking natural gas or metallurgical coke |

| Trade-offs | Lower thermal efficiency and unit capacity vs. shaft furnaces |

Optimize Your DRI Production with KINTEK Expertise

Are you looking to maximize your ironmaking efficiency using non-coking coal or other solid fuels? KINTEK provides industry-leading thermal solutions backed by expert R&D and precision manufacturing.

Our extensive range of high-temperature equipment includes Rotary, Muffle, Tube, Vacuum, and CVD systems, all of which can be fully customized to meet your unique metallurgical and laboratory requirements. Whether you are refining DRI processes or developing new materials, we deliver the durability and control you need.

Ready to enhance your production capabilities? Contact us today to discuss your custom furnace needs!

Visual Guide

References

- Tetiana Golub, Molchanov Lavr. ESTABLISHMENT OF THERMODYNAMICAL AND PHYSICO-CHEMICAL PREREQUISITES FOR DIRECT OBTAINING IRON BY THERMOLISIS OF OXIDES. DOI: 10.31319/2519-2884.47.2025.1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How is the appropriate temperature profile for a rotary kiln determined? Unlock Precision with TGA Analysis

- What are the benefits of vibration sensors and LSTM for rotary furnace diagnosis? Gain 94% Predictive Accuracy

- How do vibrational feeder specifications impact rotary kiln efficiency? Optimize Your Lab's Material Flow & Stability

- What are some common applications of rotary tube furnaces? Unlock Efficient Bulk Material Processing

- How does the design of a rotary furnace promote material processing? Achieve Uniform Heating and Efficient Throughput

- How are rotary furnaces used in calcination processes? Unlock Efficient Thermal Decomposition for Your Materials

- In what ways are rotary furnaces environmentally friendly? Boost Energy Efficiency & Waste Recycling

- What are the advantages of rotary tube furnaces in fuel compatibility? Boost Efficiency and Cut Costs