The defining fuel advantage of a rotary tube furnace is its inherent versatility. These systems are engineered to operate effectively using a wide spectrum of energy sources, including pulverized solid fuels, various gaseous fuels, and different grades of liquid fuel. This multi-fuel compatibility is not just a feature but a strategic asset, allowing operators to adapt their energy source based on cost, availability, and specific processing requirements.

The core value of a rotary tube furnace's fuel compatibility lies beyond simple flexibility. It empowers you to decouple your operation from a single fuel source, creating resilience against market volatility and enabling precise alignment of your energy choice with your specific thermal processing goals.

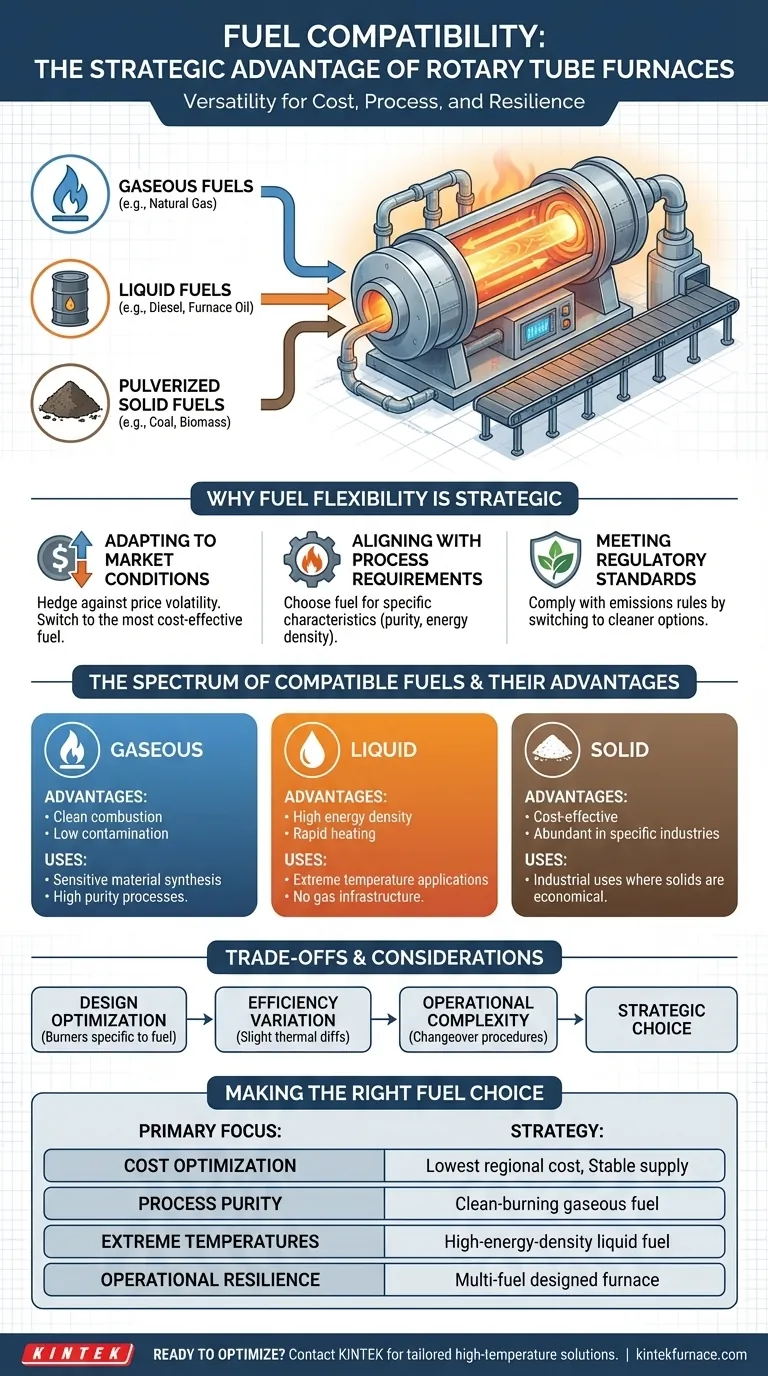

Why Fuel Flexibility is a Strategic Advantage

The ability to use different fuels is more than a convenience; it is a fundamental design benefit that impacts operational cost, resilience, and process quality. It allows you to make strategic decisions that directly affect your bottom line and product output.

Adapting to Market Conditions

Fuel prices and availability are in constant flux. A furnace capable of running on natural gas, diesel, or another source provides a powerful hedge against price spikes or supply chain disruptions.

This adaptability allows an operator to switch to the most cost-effective fuel available at any given time, significantly reducing long-term operational expenditures.

Aligning with Process Requirements

Different fuels have distinct combustion characteristics. The choice of fuel is not just about generating heat; it's about controlling the processing environment.

For example, natural gas is often chosen for its clean-burning properties, minimizing potential contamination in sensitive material synthesis. In contrast, certain furnace oils may be selected for their high energy density to achieve extreme processing temperatures.

Meeting Regulatory Standards

Environmental regulations can dictate which fuels are permissible in a given region. A multi-fuel system offers the flexibility to comply with current and future emissions standards by switching to cleaner-burning alternatives as required.

The Spectrum of Compatible Fuels

Rotary tube furnaces are engineered to accommodate the three primary forms of fuel, though specific furnace models may be optimized for a subset of these.

Gaseous Fuels

Natural gas is a common choice due to its wide availability, relatively low cost, and clean combustion. Its use simplifies emissions control and is ideal for processes where material purity is critical.

Liquid Fuels

This category includes diesel and various grades of furnace oil. These fuels are valued for their high energy density, making them effective for applications requiring rapid heating or extremely high temperatures. They also serve as a crucial alternative in locations where natural gas infrastructure is unavailable.

Pulverized Solid Fuels

The ability to burn pulverized solids, such as certain types of coal or biomass, showcases the furnace's robust design. This option is typically reserved for specific industrial applications where these materials are an abundant and economical fuel source.

Understanding the Trade-offs and Design Considerations

While versatile, the practical application of multi-fuel capability comes with important considerations. A furnace's design dictates its true flexibility.

Design Is Not Universal

A furnace's burner system, controls, and materials are often optimized for a specific fuel type. While a furnace may be capable of using multiple fuels, switching between them may require physical modifications to the burner or adjustments to the control system.

True multi-fuel readiness must be a consideration during the initial furnace specification and design phase.

Efficiency and Fuel Type

The overall energy efficiency of a rotary tube furnace is excellent due to its superior insulation and indirect heating method. However, the thermal efficiency can still vary slightly between fuel types.

The combustion properties of each fuel impact heat transfer rates and exhaust energy loss, creating minor differences in overall performance that should be factored into operational planning.

Operational Complexity

Switching between fuel sources is not always a seamless process. It can involve purging fuel lines, changing burner nozzles, and recalibrating the furnace's thermal profile. These changeover procedures require trained personnel and add a layer of operational complexity.

Making the Right Fuel Choice for Your Operation

Your optimal fuel strategy depends entirely on your primary operational driver. Use these guidelines to inform your decision when selecting or operating a rotary tube furnace.

- If your primary focus is cost optimization: Prioritize the fuel with the lowest regional cost and most stable supply chain, and ensure your furnace is configured to run it with maximum efficiency.

- If your primary focus is process purity: Select a clean-burning gaseous fuel like natural gas to minimize the risk of product contamination.

- If your primary focus is reaching extreme temperatures: Utilize a high-energy-density liquid fuel like diesel or furnace oil, provided your furnace is designed for it.

- If your primary focus is operational resilience: Invest in a furnace explicitly designed for multi-fuel capability to safeguard your operation against price shocks and supply interruptions.

Understanding these fuel dynamics transforms your furnace from a simple piece of equipment into a strategic tool for process and cost control.

Summary Table:

| Fuel Type | Key Advantages | Common Uses |

|---|---|---|

| Gaseous (e.g., Natural Gas) | Clean combustion, low contamination, widely available | Sensitive material synthesis, processes requiring high purity |

| Liquid (e.g., Diesel, Furnace Oil) | High energy density, rapid heating, extreme temperatures | High-temperature applications, areas without gas infrastructure |

| Pulverized Solid (e.g., Coal, Biomass) | Cost-effective, abundant in specific industries | Industrial uses where solids are economical and available |

Ready to optimize your thermal processing with a versatile rotary tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, helping you achieve superior fuel flexibility, cost savings, and process resilience. Contact us today to discuss how our tailored furnace solutions can benefit your laboratory!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating