At its core, the design of a rotary furnace promotes material processing through two fundamental mechanical principles: continuous rotation and a slight downward inclination. This combination creates a dynamic environment that actively transports, mixes, and uniformly heats material as it moves from the feed end to the discharge end, ensuring a consistent and efficient thermal treatment.

The genius of the rotary furnace is not just in its ability to heat material, but in its design to physically manipulate that material throughout the process. This active handling prevents common issues like hot spots and clumping, ensuring a level of uniformity that static furnaces cannot match.

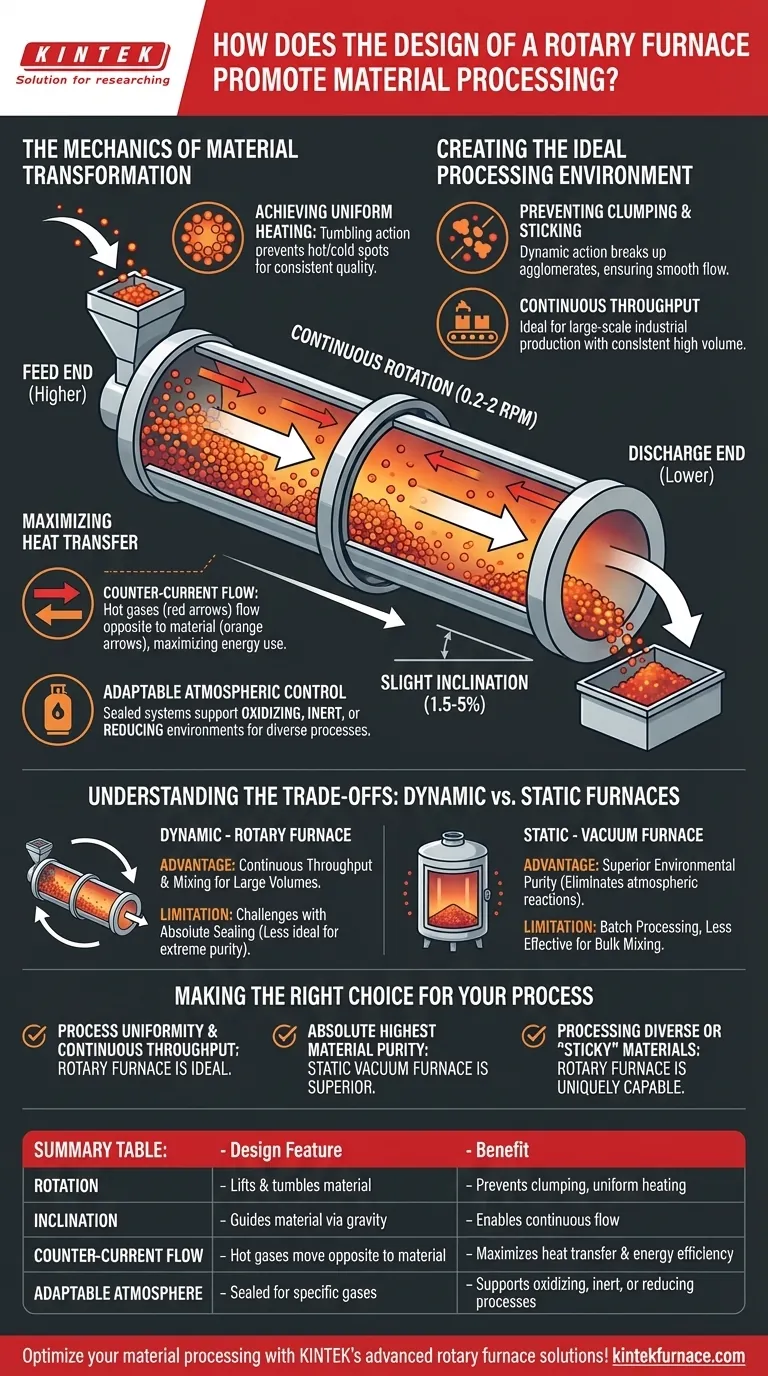

The Mechanics of Material Transformation

A rotary furnace is far more than a simple heated tube. Its specific design elements are engineered to solve key challenges in bulk material processing, from ensuring every particle is treated equally to maximizing energy efficiency.

The Role of Inclination and Rotation

The furnace body is a long cylinder set at a slight angle, typically between 1.5% and 5%. This gentle slope uses gravity to guide material continuously from the higher feed end to the lower discharge end.

Simultaneously, the cylinder rotates slowly, usually between 0.2 and 2 revolutions per minute. This rotation lifts and tumbles the material, guaranteeing that new surfaces are constantly exposed.

Achieving Uniform Heating

The constant tumbling action is critical for achieving a uniform temperature throughout the material bed. It prevents the formation of hot or cold spots, which could lead to inconsistent product quality.

By ensuring every particle receives similar exposure to the heat source, the furnace produces a highly homogenous final product, which is vital for processes like smelting or catalyst roasting.

Maximizing Heat Transfer with Counter-Current Flow

In many designs, the hot gases used for heating flow in the opposite direction of the material. This counter-current flow is a highly efficient heat transfer method.

As the coolest material enters the furnace, it meets the coolest gases, and as it nears the discharge end, the hottest material meets the hottest gases. This maintains an effective temperature difference along the entire length of the furnace, maximizing energy use.

Creating the Ideal Processing Environment

Beyond the mechanical handling of material, the rotary furnace design allows for precise control over the chemical environment, making it a versatile tool for a wide range of applications.

Adaptable Atmospheric Control

Rotary furnaces can be engineered to operate under specific atmospheres. Whether a process requires an oxidizing (oxygen-rich), inert (non-reactive), or reducing (oxygen-deficient) environment, the system can be sealed and controlled to meet these needs.

This adaptability makes them suitable for everything from calcination in air to specialized chemical reactions in a nitrogen or argon atmosphere.

Preventing Clumping and Sticking

For materials that tend to become sticky, agglomerate, or form clumps when heated, the dynamic action of a rotary furnace is a significant advantage.

The continuous tumbling breaks up potential clumps and prevents material from fusing to the furnace walls, ensuring smooth operation and consistent flow.

Understanding the Trade-offs: Dynamic vs. Static Furnaces

No single technology is perfect for every task. The primary advantage of a rotary furnace is its dynamic nature, but this also creates limitations compared to static, sealed systems like a vacuum furnace.

Advantage: Continuous Throughput and Mixing

The key strength of a rotary furnace is its ability to process a continuous flow of material while ensuring it is thoroughly mixed. This makes it ideal for large-scale industrial production where consistency across large volumes is paramount. Static batch furnaces simply cannot offer this level of dynamic treatment.

Limitation: Environmental Purity

While a rotary furnace can control its atmosphere, the rotating seals at the feed and discharge ends make it difficult to achieve the perfect seal of a static vacuum furnace. A vacuum furnace is designed to remove the atmosphere entirely, eliminating the risk of oxidation and contamination.

This makes a vacuum furnace the superior choice for processing highly sensitive materials, such as those used in electronics or aerospace, where absolute purity is non-negotiable.

Making the Right Choice for Your Process

Selecting the correct furnace technology depends entirely on your primary processing goal.

- If your primary focus is process uniformity and continuous throughput: A rotary furnace is the ideal choice, as its design inherently guarantees consistent mixing and efficient heating for large volumes.

- If your primary focus is achieving the absolute highest material purity: A static vacuum furnace is superior, as its sealed chamber eliminates atmospheric reactions and contamination.

- If your primary focus is processing diverse or "sticky" materials: The rotary furnace's tumbling action makes it a uniquely capable and adaptable solution for challenging material types.

Ultimately, understanding these fundamental design principles empowers you to select the right tool for your specific material transformation goal.

Summary Table:

| Design Feature | Function | Benefit |

|---|---|---|

| Rotation | Lifts and tumbles material | Prevents clumping, ensures uniform heating |

| Inclination | Guides material via gravity | Enables continuous flow from feed to discharge |

| Counter-current flow | Hot gases move opposite to material | Maximizes heat transfer and energy efficiency |

| Adaptable atmosphere | Sealed for specific gases | Supports oxidizing, inert, or reducing processes |

Optimize your material processing with KINTEK's advanced rotary furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Rotary, Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, enhancing efficiency and product quality. Contact us today to discuss how we can support your specific requirements!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- What materials can be used to make the rotating tube assembly of these furnaces? Choose the Best for Your High-Temp Needs

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes