In short, rotary tube furnaces are used for the continuous, high-temperature processing of loose bulk materials like powders and granules. Their primary applications include the large-scale manufacturing of industrial materials, such as alumina and cement clinker, and specialized chemical processes like calcination, oxidation, and the gaseous reduction of ores in industries ranging from metallurgy to materials science.

A rotary tube furnace is not just a high-temperature oven; its defining feature is the continuous rotation that tumbles the material. This unique mechanism is what makes it the superior choice for achieving exceptional thermal uniformity and promoting efficient chemical reactions in loose, bulk materials.

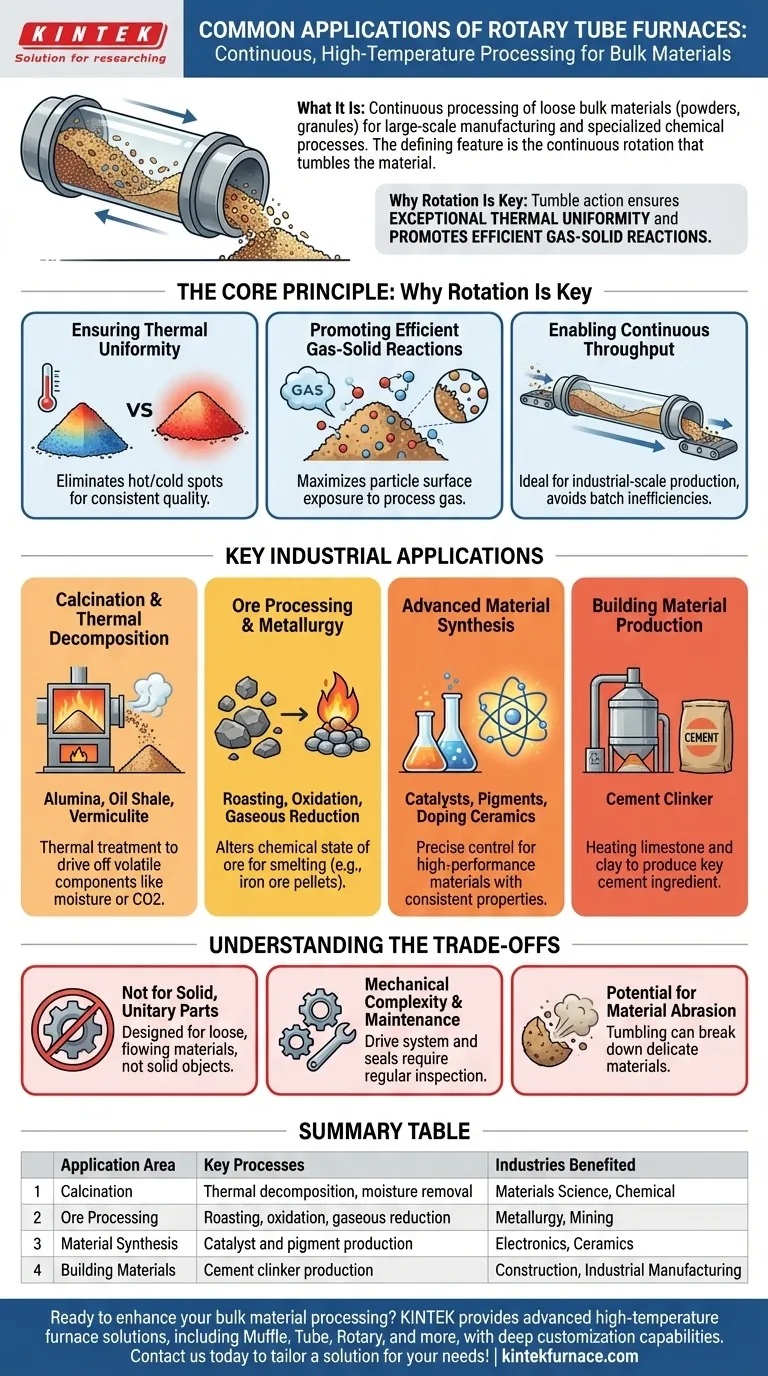

The Core Principle: Why Rotation Is Key

Understanding the applications of a rotary tube furnace begins with understanding its primary advantage: the rotation itself. Unlike a static furnace where material sits motionless, the constant tumbling is a deliberate engineering feature that unlocks specific processing capabilities.

Ensuring Thermal Uniformity

In a static furnace, a pile of powder will heat unevenly. The outer layers get hot while the core remains cool, leading to inconsistent product quality.

The gentle tumbling action of a rotary furnace constantly mixes the material, ensuring every particle is uniformly exposed to the heat source. This eliminates hot spots and cold spots, resulting in a highly consistent final product.

Promoting Efficient Gas-Solid Reactions

Many key applications, like oxidation or reduction, require a process gas to react with the solid material. Rotation is critical here.

As the material bed tumbles, it constantly exposes new particle surfaces to the furnace's controlled atmosphere. This dramatically increases the efficiency and completeness of the chemical reaction, which is vital for processes like ore roasting or catalyst synthesis.

Enabling Continuous Throughput

Rotary tube furnaces are designed for continuous operation. Raw material is fed into one end of the tilted, rotating tube and the processed material exits the other.

This design is essential for industrial-scale production where stopping to load and unload individual batches, as required by a box furnace, would be inefficient.

Key Industrial Applications in Detail

The unique advantages of rotation make these furnaces indispensable for specific, high-value processes across multiple industries.

Calcination and Thermal Decomposition

Calcination is a thermal treatment process that brings about a chemical change, such as driving off moisture, carbon dioxide, or other volatile components.

Rotary furnaces are ideal for calcining materials like alumina, oil shale, and vermiculite, where uniform heating is required to complete the decomposition process efficiently.

Ore Processing and Metallurgy

In metallurgy, rotary furnaces are used for roasting, oxidation, and gaseous reduction. These processes alter the chemical state of an ore to prepare it for smelting.

For example, they are used to manufacture iron ore pellets or to analyze metallurgical slags, where controlled reactions at high temperatures are fundamental to the process.

Advanced Material Synthesis

The precise control offered by these furnaces makes them valuable for creating high-performance materials.

Applications include synthesizing catalysts and pigments, where consistency is paramount, and doping ceramics with rare-earth metals to achieve specific electronic or optical properties.

Building Material Production

The manufacturing of cement clinker is a classic application of large-scale rotary kilns, a type of rotary furnace.

The process involves heating limestone and clay to sintering temperatures in a massive rotating furnace to produce the key ingredient for modern cement.

Understanding the Trade-offs

While powerful, rotary tube furnaces are not a universal solution. Their specialized design comes with clear limitations.

Not for Solid, Unitary Parts

These furnaces are designed exclusively for processing powders, granules, or other loose, flowing materials. They cannot be used for the heat treatment of a single, solid object or component.

Mechanical Complexity and Maintenance

The drive system, seals, and bearings that enable the tube's rotation add mechanical complexity compared to a simple static furnace. These components require regular inspection and maintenance to ensure reliable operation.

Potential for Material Abrasion

The tumbling action, while beneficial for heating, can cause attrition in very delicate or friable materials. This can lead to the generation of fine dust or the breakdown of the desired particle shape, which must be considered during process design.

Making the Right Choice for Your Goal

Selecting the correct furnace technology depends entirely on your material and your processing objective.

- If your primary focus is large-scale, continuous production: A rotary tube furnace is ideal for the high-throughput processing of materials like minerals or cement clinker.

- If your primary focus is a uniform chemical reaction: This furnace excels at processes like oxidation or reduction where every particle must be equally exposed to a controlled atmosphere.

- If your primary focus is research and development: A lab-scale rotary tube furnace offers precise control for synthesizing novel powders and catalysts with highly consistent properties.

- If you are processing large, solid objects or extremely fragile powders: A static box furnace or a standard tube furnace is likely a more suitable choice.

Ultimately, the decision to use a rotary tube furnace hinges on its unparalleled ability to uniformly process bulk materials in a dynamic environment.

Summary Table:

| Application Area | Key Processes | Industries Benefited |

|---|---|---|

| Calcination | Thermal decomposition, moisture removal | Materials Science, Chemical |

| Ore Processing | Roasting, oxidation, gaseous reduction | Metallurgy, Mining |

| Material Synthesis | Catalyst and pigment production | Electronics, Ceramics |

| Building Materials | Cement clinker production | Construction, Industrial Manufacturing |

Ready to enhance your bulk material processing with precision and efficiency? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in metallurgy, materials science, or chemical processing, our expertise ensures optimal performance and reliability. Contact us today to discuss how we can tailor a solution for your specific needs!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What are the common applications of a rotary tube furnace? Achieve Uniform Heating for Powders and Granules

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control

- How do rotary tube furnaces support real-time monitoring and continuous processing? Boost Efficiency with Continuous Flow & Live Observation

- What are the benefits of continuous sample movement in rotary tube furnaces? Boost Uniformity and Efficiency