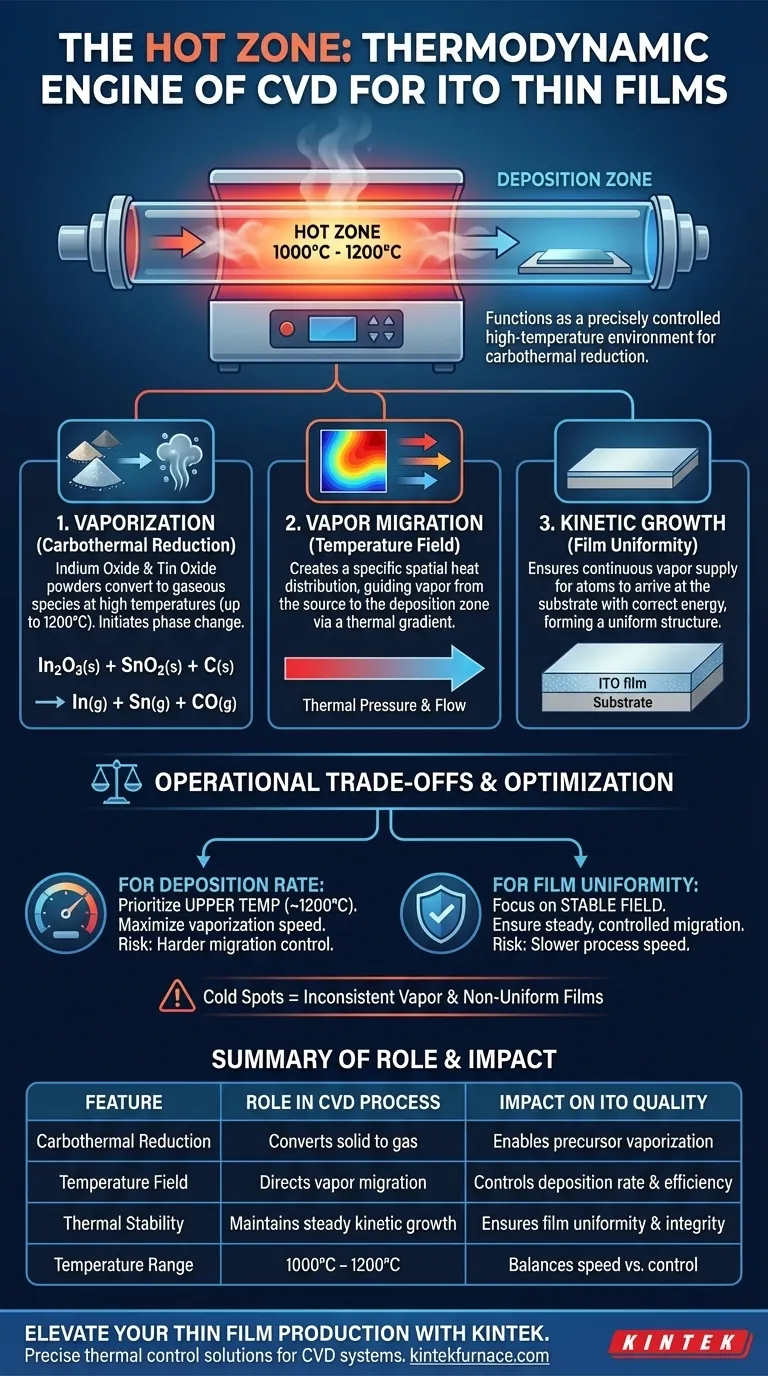

The hot zone functions as the thermodynamic engine of the Chemical Vapor Deposition (CVD) process. It provides a precisely controlled high-temperature environment, typically ranging between 1000°C and 1200°C, which is required to initiate the chemical transformation of solid precursors. Specifically, this heat triggers the carbothermal reduction of Indium Oxide and Tin Oxide powders, converting them into the gaseous metallic species necessary for film formation.

The hot zone does more than simply melt or vaporize materials; it establishes a specific temperature field that dictates the entire transport mechanism. By controlling the saturation and migration of vapor from the source to the deposition zone, the hot zone acts as the primary regulator for the kinetic growth and structural quality of the Indium Tin Oxide (ITO) thin film.

Mechanisms of Action within the Hot Zone

Vaporization via Carbothermal Reduction

The primary function of the hot zone is to facilitate a phase change through chemical reduction. The furnace must maintain extreme temperatures to enable the carbothermal reduction of precursor powders.

In this specific process, Indium Oxide (In2O3) and Tin Oxide (SnO2) are exposed to temperatures up to 1200°C. This thermal energy breaks down the solid powders, converting them into gaseous metallic species that are ready for transport.

Guiding Vapor Migration

Once the precursors are vaporized, the hot zone is responsible for moving them effectively. The furnace creates a distinct temperature field—a spatial distribution of heat—that influences the flow of gases.

This thermal gradient forces the saturated vapor to migrate away from the source and toward the cooler deposition zone. Without this directed thermal pressure, the vapor would not travel efficiently, leading to poor deposition rates.

Enabling Kinetic Growth

The quality of the final ITO film is determined by how the vapor arrives at the substrate. The hot zone ensures that the supply of gaseous material is continuous and stable.

By maintaining a consistent generation of vapor, the hot zone supports proper kinetic growth. This ensures that the Indium and Tin atoms arrive at the substrate with the correct energy and density to form a uniform thin film structure.

Understanding the Operational Trade-offs

Thermal Precision vs. Process Speed

While higher temperatures generally increase the vaporization rate, they introduce stability risks. Pushing the hot zone to the upper limit (1200°C) creates more vapor quickly but can make the migration rate harder to control.

If the vapor arrives at the deposition zone too aggressively, it may lead to rough or non-uniform films. Conversely, operating at the lower end (1000°C) offers better control but may significantly slow down the production process.

The Challenge of Uniformity

The hot zone must provide uniform heat across the entire precursor load. Any "cold spots" within the hot zone will result in incomplete vaporization or inconsistent precursor ratios.

In CVD processes, non-uniform heating leads to fluctuations in the vapor composition. This can cause the final ITO film to have varying electrical or optical properties across its surface, compromising the device's performance.

Making the Right Choice for Your Goal

To optimize your ITO thin film production, you must tune the hot zone parameters based on your specific output requirements.

- If your primary focus is Deposition Rate: Prioritize the upper temperature range (near 1200°C) to maximize the vaporization speed of the precursor powders.

- If your primary focus is Film Uniformity: Focus on stabilizing the temperature field to ensure a steady, controlled migration of vapor to the deposition zone.

Success in CVD lies not just in generating heat, but in precisely directing the thermal energy to control material transport.

Summary Table:

| Feature | Role in CVD Process | Impact on ITO Quality |

|---|---|---|

| Carbothermal Reduction | Converts solid In2O3/SnO2 to gas | Enables essential precursor vaporization |

| Temperature Field | Directs vapor migration | Controls deposition rate and efficiency |

| Thermal Stability | Maintains steady kinetic growth | Ensures film uniformity and structural integrity |

| Temperature Range | 1000°C - 1200°C | Balances production speed vs. process control |

Elevate Your Thin Film Production with KINTEK

Precise thermal control is the backbone of high-quality CVD for Indium Tin Oxide (ITO) thin films. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique laboratory or industrial needs. Our advanced furnace technology ensures the stable temperature fields and precise kinetic growth required for superior material science results.

Ready to optimize your deposition process? Contact KINTEK Today to Consult with Our Experts

Visual Guide

References

- Muchammad Yunus, Azianty Saroni. Effect of Deposition Temperature on The Structural and Crystallinity Properties of Self-Catalyzed Growth Indium Tin Oxide (ITO) Thin Film Using CVD Technique. DOI: 10.24191/srj.v22i2.23000

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What role does a high-temperature tube furnace play in synthesizing SiQDs? Precision Control for HSQ Pyrolysis

- Why is a high-temperature tube furnace required for MoS2 and WS2 thin films? Achieve 2H Crystalline Phase Excellence

- How can the purity of the atmosphere inside a vacuum tube experimental furnace be increased? Master Vacuum Purging for Pristine Results

- What applications is a Split Tube Furnace (Single Zone) suitable for? Ideal for Uniform Heating and Easy Access

- What are the key features of an alumina tube furnace? Achieve Precise High-Temp Processing

- Why are controlled atmosphere and vacuum operations important for tube furnaces? Protect Materials and Enable Precision Reactions

- How does high-purity Nitrogen thermal annealing in a tube furnace facilitate the observation of Violet Phosphorus?

- What conditions does a tube vacuum furnace provide for zinc sulfide distillation? Optimize Your Zinc Ore Processing