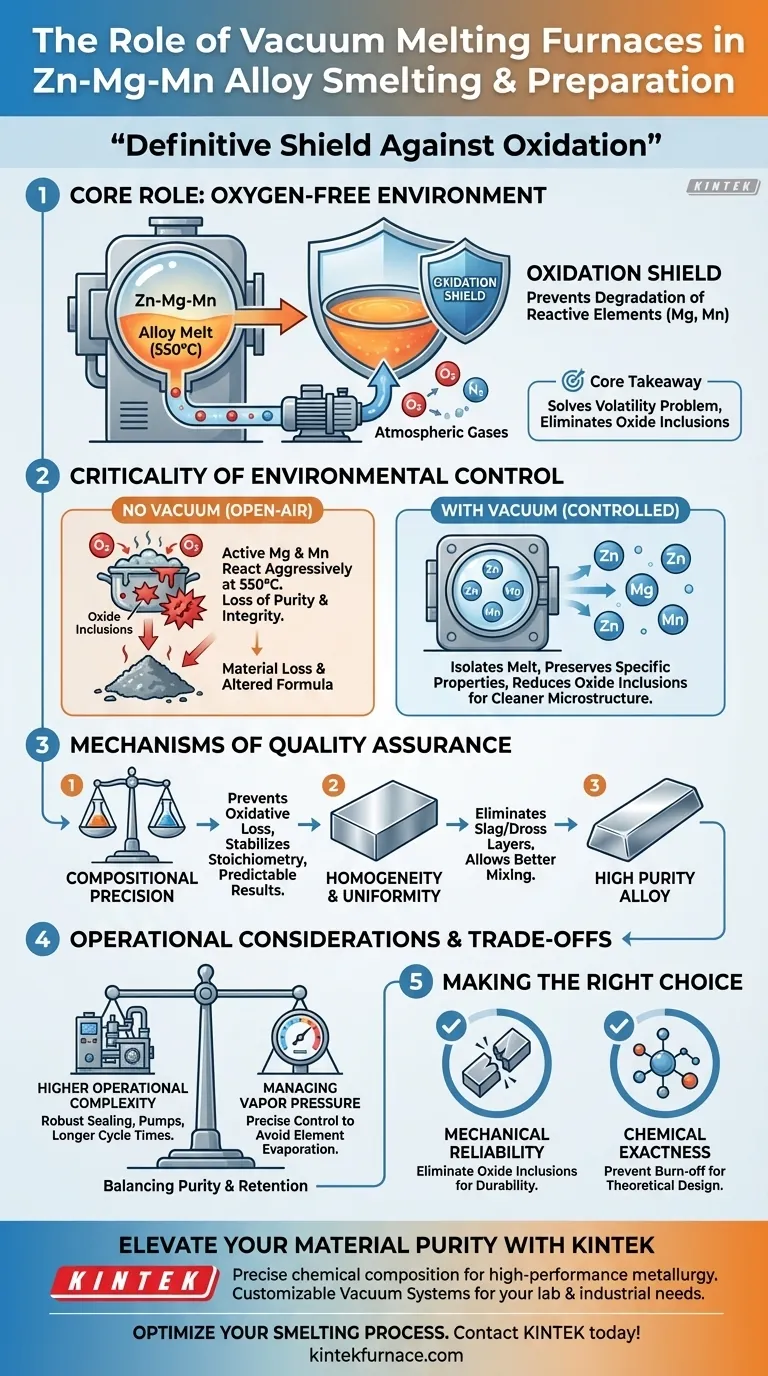

The primary role of a vacuum melting furnace in Zn-Mg-Mn alloy production is to act as a definitive shield against oxidation. By creating a controlled, oxygen-free environment during the high-temperature melting process at 550°C, the furnace prevents the degradation of highly reactive elements like magnesium and manganese. This ensures the final alloy maintains a precise chemical composition and high purity.

Core Takeaway: The vacuum melting furnace solves the volatility problem inherent in magnesium and manganese. By eliminating atmospheric oxygen during both melting and casting, it prevents the formation of oxide inclusions that would otherwise compromise the alloy's structural integrity and chemical exactness.

The Criticality of Environmental Control

Protecting Highly Active Elements

Zinc-Magnesium-Manganese (Zn-Mg-Mn) alloys rely heavily on the specific properties of magnesium and manganese. However, these elements are chemically "active," meaning they react aggressively with oxygen.

At the standard melting temperature of 550°C, this reactivity peaks. Without a vacuum environment, these elements would rapidly oxidize, leading to a loss of material and an alteration of the alloy's intended formula. The vacuum furnace isolates the melt, ensuring that the magnesium and manganese you add are the magnesium and manganese that end up in the final product.

Reducing Oxide Inclusions

Oxidation does more than just consume elements; it creates waste. When magnesium or manganese reacts with oxygen, they form oxide inclusions—microscopic solid particles trapped within the metal.

These inclusions act as stress points and impurities. By conducting both the melting and casting stages under vacuum, the furnace significantly reduces the presence of these oxides. This results in a "cleaner" microstructure and a higher purity alloy.

Mechanisms of Quality Assurance

Ensuring Compositional Precision

In advanced metallurgy, hitting the exact chemical target is non-negotiable. Because the vacuum furnace prevents the oxidative loss of active ingredients, it stabilizes the stoichiometry of the melt.

This allows for predictable, repeatable results. You do not need to "over-charge" the furnace with excess magnesium to compensate for anticipated burn-off, making the process more efficient and controlled.

Homogeneity and Uniformity

While the primary function is protection, the controlled environment of a vacuum furnace often facilitates better homogeneity. By removing the variable of atmospheric interference, the melt can settle and mix without the formation of slag or dross layers that typically separate elements in open-air smelting.

Operational Considerations and Trade-offs

The Cost of Purity

While vacuum melting ensures superior quality, it introduces higher operational complexity compared to atmospheric furnaces. The equipment requires robust sealing, vacuum pumps, and longer cycle times to establish the necessary environment (e.g., specific pressure levels like 0.055-0.088 Pa in comparable sintering contexts).

Managing Vapor Pressure

A nuanced challenge in vacuum melting is managing the vapor pressure of volatile elements. While the vacuum removes unwanted gases, operators must ensure the pressure is not so low that it causes the evaporation of the Zinc or Magnesium themselves. Precise pressure control is required to balance purification with retention.

Making the Right Choice for Your Goal

When deciding on the preparation method for Zn-Mg-Mn alloys, consider your specific performance requirements:

- If your primary focus is mechanical reliability: The vacuum furnace is essential to eliminate oxide inclusions that cause premature fracture or fatigue.

- If your primary focus is chemical exactness: Use vacuum melting to prevent the "burn-off" of magnesium and manganese, ensuring the alloy matches the theoretical design.

Ultimately, the vacuum melting furnace is not just a heating vessel; it is a chemical process control tool that guarantees the purity required for high-performance applications.

Summary Table:

| Feature | Impact on Zn-Mg-Mn Alloy Production |

|---|---|

| Vacuum Environment | Prevents oxidation of active elements like Mg and Mn |

| Oxide Inclusion Reduction | Enhances structural integrity and cleaner microstructure |

| Atmospheric Control | Stabilizes stoichiometry and ensures chemical precision |

| Processing Temperature | Optimized at 550°C for reactive element stability |

| Melt Homogeneity | Eliminates slag/dross layers for uniform material mixing |

Elevate Your Material Purity with KINTEK

Precise chemical composition is the foundation of high-performance metallurgy. Backed by expert R&D and manufacturing, KINTEK offers high-tier Vacuum, Muffle, Tube, Rotary, and CVD systems, all fully customizable for your unique lab and industrial needs.

Whether you are refining Zn-Mg-Mn alloys or developing next-generation materials, our vacuum solutions provide the definitive shield against oxidation you need for repeatable, high-quality results.

Ready to optimize your smelting process? Contact KINTEK today to discuss your custom furnace requirements!

Visual Guide

References

- Chengwu Lu, Jie Xu. Biodegradable zinc alloys with high strength and suitable mechanical integrity as bone repair metals. DOI: 10.1038/s41598-024-78842-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What role does a vacuum annealing furnace play in AlCoCrFeNi2.1 joints? Ensure Microstructural Stability & Pure Diffusion

- Why is a high-temperature vacuum drying oven necessary for hard carbon? Protect Your Material Integrity

- How do graphite heating elements function in vacuum furnaces? Unlocking Extreme Heat for Critical Processes

- Why is a vacuum furnace beneficial for applications requiring high purity? Achieve Unmatched Material Purity and Performance

- What role does a vacuum annealing furnace play in evaluating Ag2S1-xTex phase stability? Map Material Limits Precisely

- What industries benefit from using vacuum furnaces? Achieve Purity and Precision in High-Stakes Sectors

- What are the key steps in a typical vacuum brazing treatment? Master the Process for Strong, Clean Joints

- Why is a vacuum annealing furnace required for Cu2Co1-xNaxSnS4 films? Optimize Your Thin Film Crystallization