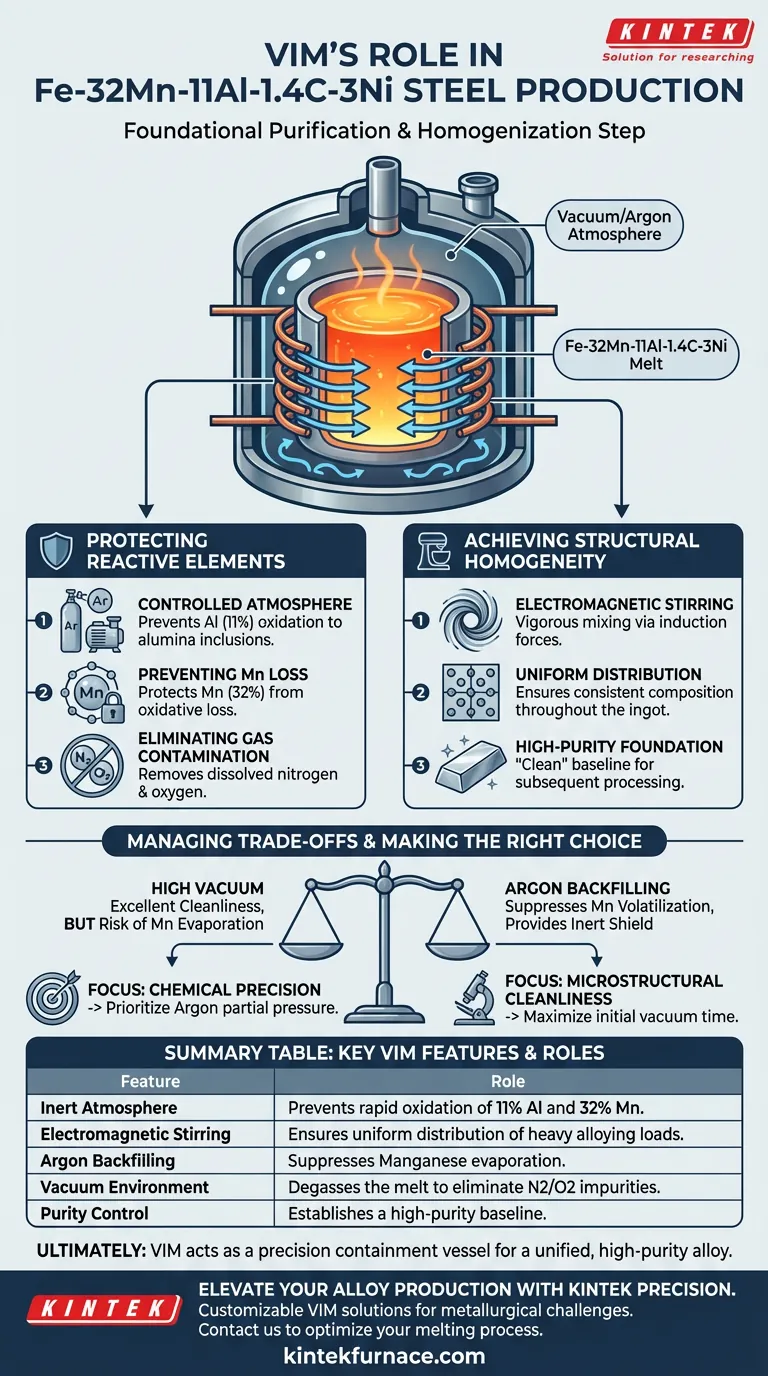

Vacuum Induction Melting (VIM) serves as the foundational purification step for producing Fe-32Mn-11Al-1.4C-3Ni steel. It primarily functions to shield the highly reactive alloying elements—specifically Aluminum and Manganese—from oxidation through a controlled argon-protected environment, while utilizing electromagnetic forces to ensure the heavy alloying load is thoroughly mixed.

Core Takeaway The production of this specific high-alloy steel relies on VIM to solve two critical challenges: preventing the rapid oxidation of its high Aluminum (11%) and Manganese (32%) content, and achieving chemical uniformity through electromagnetic stirring. Without this controlled environment, the alloy would suffer from severe elemental loss and high impurity levels.

Protecting Reactive Elements

For an alloy with such high concentrations of reactive metals, standard melting methods would result in immediate degradation. VIM addresses the specific chemical vulnerabilities of the Fe-32Mn-11Al-1.4C-3Ni composition.

Controlling the Atmosphere

The furnace operates within a vacuum or a controlled inert gas atmosphere, typically using argon. This isolation is critical because the 11% Aluminum content is extremely prone to reacting with oxygen to form alumina inclusions.

Preventing Manganese Loss

Manganese, present at 32%, is highly susceptible to oxidative loss during melting. The VIM furnace’s protective environment prevents this oxidation, ensuring the final ingot retains the precise chemical composition required for the alloy's performance.

Eliminating Gas Contamination

Beyond protecting the metals, the vacuum environment actively removes unwanted gases. It eliminates contamination from the ambient atmosphere, preventing nitrogen or oxygen from dissolving into the molten steel and compromising its mechanical properties.

Achieving Structural Homogeneity

Creating a homogenous alloy with such a diverse mix of elements (Iron, Manganese, Aluminum, Carbon, and Nickel) is mechanically difficult. VIM utilizes inherent physics to solve this.

Electromagnetic Stirring

The induction heating mechanism does more than just melt the metal; it generates strong electromagnetic forces within the crucible. This provides a natural, vigorous stirring action.

Uniform Element Distribution

This continuous stirring is essential for mixing the 32% Manganese and 11% Aluminum thoroughly with the Iron base. It guarantees that the chemical composition is consistent throughout the entire ingot, rather than having pockets of concentrated elements.

Creating a High-Purity Foundation

By combining gas removal with thorough mixing, VIM establishes a "clean" baseline. This high-purity foundation is a prerequisite for any subsequent thermal processing or performance evaluation of the steel.

Understanding the Trade-offs

While VIM is the superior choice for this alloy, the operator must carefully manage the process parameters to avoid specific pitfalls.

Balancing Vacuum vs. Evaporation

While a high vacuum is excellent for cleanliness, Manganese has a high vapor pressure. If the vacuum is too deep (pressure is too low), the Manganese may begin to evaporate rather than stay in the melt.

The Necessity of Argon Backfilling

To counter the evaporation risk, the process often requires backfilling the chamber with Argon gas (as noted in the primary reference). This suppresses the volatilization of Manganese while still providing an inert shield against oxidation.

Making the Right Choice for Your Goal

The specific operational parameters of the VIM furnace should be adjusted based on your primary quality metric for the steel ingot.

- If your primary focus is Chemical Precision: Prioritize the use of an Argon partial pressure atmosphere to suppress Manganese evaporation while protecting the Aluminum.

- If your primary focus is Microstructural Cleanliness: Maximize the vacuum time during the initial melt stages to ensure complete degassing before adding volatile elements.

Ultimately, the VIM furnace acts as a precision containment vessel that allows you to force chemically distinct elements into a unified, high-purity alloy without losing them to the atmosphere.

Summary Table:

| Feature | Role in Fe-32Mn-11Al-1.4C-3Ni Production |

|---|---|

| Inert Atmosphere | Prevents rapid oxidation of 11% Al and 32% Mn content. |

| Electromagnetic Stirring | Ensures uniform distribution of heavy alloying loads. |

| Argon Backfilling | Suppresses Manganese evaporation due to high vapor pressure. |

| Vacuum Environment | Degasses the melt to eliminate nitrogen and oxygen impurities. |

| Purity Control | Establishes a high-purity baseline for subsequent thermal processing. |

Elevate Your Alloy Production with KINTEK Precision

Achieving the perfect chemical balance in complex steels like Fe-32Mn-11Al-1.4C-3Ni requires more than just heat—it requires a controlled, high-purity environment. KINTEK provides industry-leading Vacuum, CVD, and Lab High-Temp Furnaces designed to protect your reactive elements and ensure structural homogeneity.

Backed by expert R&D and advanced manufacturing, our systems are fully customizable to meet your unique metallurgical challenges. Contact KINTEK today to optimize your melting process and see how our vacuum induction solutions can deliver the purity your materials demand.

Visual Guide

References

- Changwei He, Yiran Zhou. Nanosized κ-Carbide and B2 Boosting Strength Without Sacrificing Ductility in a Low-Density Fe-32Mn-11Al Steel. DOI: 10.3390/nano15010048

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How does electromagnetic stirring in IGBT induction melting furnaces improve melt quality? Achieve Superior Metal Purity and Homogeneity

- Why is maintaining a low-pressure vacuum environment necessary during induction heating graphitization?

- What are the key features of high temperature melt furnaces? Achieve Precise Melting for Metals and Alloys

- How are induction furnaces used in investment casting? Achieve Precision Melting for High-Quality Cast Parts

- Why is precise temperature control in an electric melting furnace essential for AZ91D/Si3N4/WGP composites?

- What is the function of a Vacuum Induction Melting Furnace? Advanced Metallurgy for 440 MPa Copper-Bearing Steel

- What makes IGBT technology advantageous for induction heating? Achieve Precision, Efficiency, and Speed

- What are eddy currents and how are they generated in an induction heater? | Efficient Heating Explained