At their core, high-temperature melt furnaces are defined by a few critical capabilities. These include the ability to operate at extreme temperatures (often exceeding 1000°C), precise control over the heating process, uniform temperature distribution across the material, and durable construction designed to withstand thermal stress. Many advanced models also offer atmosphere control to prevent contamination during the melting process.

The defining characteristic of a high-quality melt furnace is not just its ability to reach extreme temperatures, but its capacity to create a highly controlled and repeatable environment. This precision is what transforms raw materials into components with specific, desired properties.

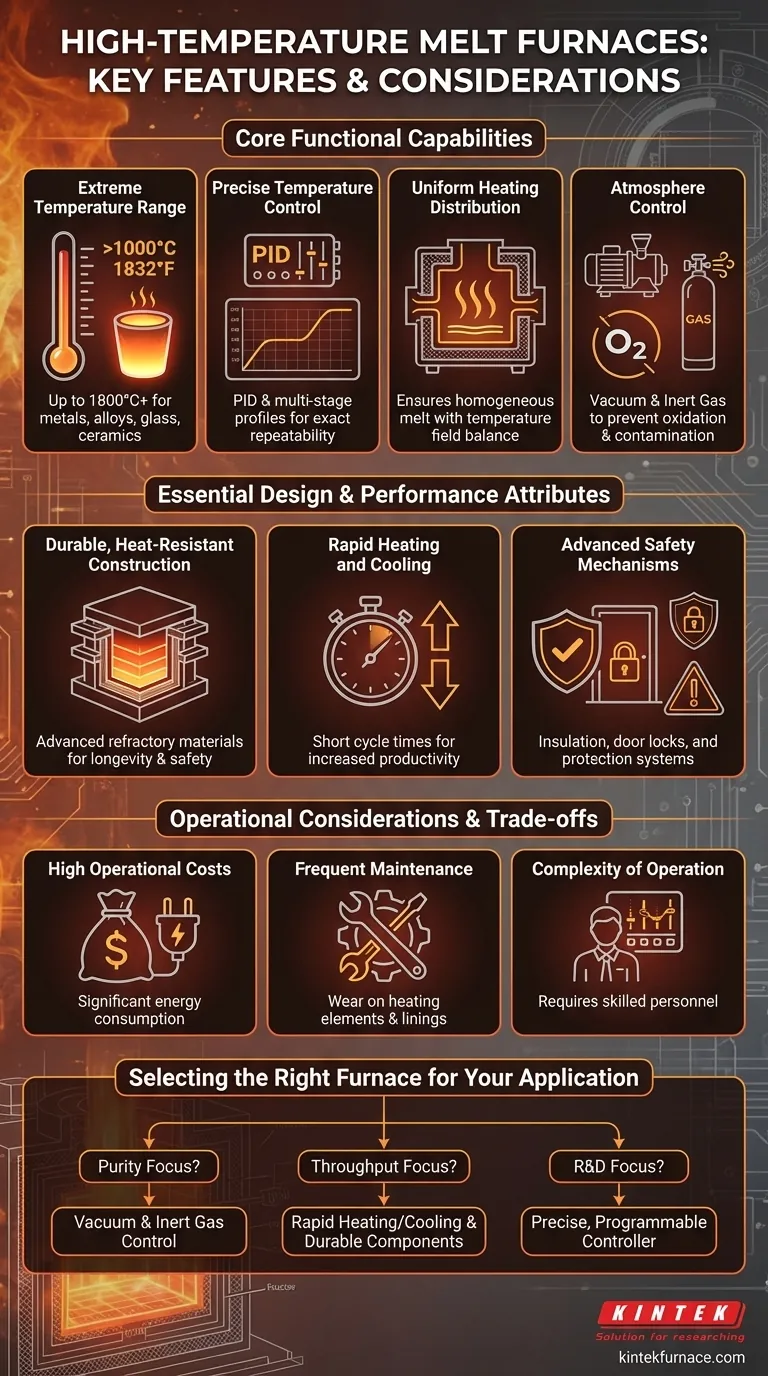

Core Functional Capabilities

To achieve consistent and high-quality results, these furnaces rely on a combination of integrated systems. Each feature serves a distinct purpose in the melting process.

Extreme Temperature Range

A furnace's primary job is to generate heat, and these systems are engineered to operate reliably at temperatures above 1,000°C (1832°F), with some specialized models reaching 1,800°C (3272°F) or higher.

This capability makes them essential for processing a wide range of materials, including industrial metals, specialty alloys, glass, and advanced ceramics.

Precise Temperature Control

Modern furnaces use sophisticated control systems, often with Proportional-Integral-Derivative (PID) controllers or multi-stage programming.

This allows operators to execute precise heating and cooling profiles, which is critical for achieving specific metallurgical phases or material structures. The result is high repeatability from one batch to the next.

Uniform Heating Distribution

Ensuring the temperature is even throughout the chamber—known as temperature field balance—is crucial. It prevents hot spots that could damage the material or cold spots that lead to incomplete melting.

Uniform heating guarantees that the entire melt reaches the target temperature, leading to a homogenous final product.

Atmosphere Control (Vacuum & Inert Gas)

Many applications, especially those involving reactive metals like titanium or high-purity alloys, require a controlled atmosphere. Furnaces achieve this in two primary ways.

First is a vacuum system, which removes oxygen and other contaminants that can cause oxidation. Second is the introduction of an inert gas, such as argon or nitrogen, to create a protective, non-reactive environment for the melt.

Essential Design & Performance Attributes

Beyond the core functions, the furnace's physical design and operational efficiency are key features that determine its longevity, safety, and productivity.

Durable, Heat-Resistant Construction

The furnace chamber and insulation are built from advanced refractory materials designed to withstand extreme thermal cycling without degrading. This robust construction is fundamental to the furnace's longevity and operational safety.

Rapid Heating and Cooling

Efficiency is often measured in cycle time. The ability to heat up and cool down quickly significantly increases productivity and throughput. This feature is especially important in production environments where time is a critical factor.

Advanced Safety Mechanisms

Operating at such high temperatures presents inherent risks. These furnaces are equipped with multiple safety features, including high-grade thermal insulation to keep the external surface temperature low, secure door-locking mechanisms, and over-temperature protection systems.

Understanding the Trade-offs

While powerful, high-temperature melt furnaces come with significant operational considerations that must be weighed against their benefits.

High Operational Costs

The energy required to reach and maintain temperatures above 1,000°C is substantial, leading to high electricity or gas consumption. This is a primary driver of the furnace's total cost of ownership.

Frequent Maintenance Requirements

The extreme environment causes significant wear and tear on components like heating elements, thermocouples, and refractory linings. Regular inspection and replacement are necessary to ensure reliable and safe operation.

Complexity of Operation

These are not simple machines. Operating a high-temperature furnace, especially one with advanced atmosphere and temperature controls, requires skilled and well-trained personnel to manage processes and ensure safety.

Selecting the Right Furnace for Your Application

Your choice of furnace should be dictated by the specific material properties and production goals you need to achieve.

- If your primary focus is high-purity alloys or reactive metals: Prioritize a furnace with advanced vacuum and inert gas atmosphere control to prevent oxidation.

- If your primary focus is high-throughput production: Seek a furnace optimized for rapid heating/cooling cycles and built with exceptionally durable components to minimize downtime.

- If your primary focus is research and development: Select a furnace with a highly precise, multi-stage programmable temperature controller to allow for experimental flexibility and process repeatability.

Ultimately, choosing the right furnace is about matching its specific control capabilities to your desired material outcome.

Summary Table:

| Feature | Description |

|---|---|

| Extreme Temperature Range | Operates reliably above 1,000°C, up to 1,800°C or higher for metals, alloys, glass, and ceramics. |

| Precise Temperature Control | Uses PID controllers for accurate heating/cooling profiles, ensuring high repeatability. |

| Uniform Heating Distribution | Maintains even temperature to prevent hot/cold spots, ensuring homogeneous melts. |

| Atmosphere Control | Supports vacuum and inert gas systems to prevent oxidation and contamination. |

| Durable Construction | Built with heat-resistant materials for longevity and safety under thermal stress. |

| Rapid Heating/Cooling | Enables fast cycle times to boost productivity and throughput. |

| Advanced Safety Mechanisms | Includes insulation, door locks, and over-temperature protection for safe operation. |

Ready to elevate your material processing with a high-temperature melt furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental and production requirements. Whether you're working with metals, alloys, glass, or ceramics, we can help you achieve superior results with reliable, efficient equipment. Contact us today to discuss how we can support your laboratory's success!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How do you prevent maintenance on a muffle furnace? Extend Lifespan with Proactive Care

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment