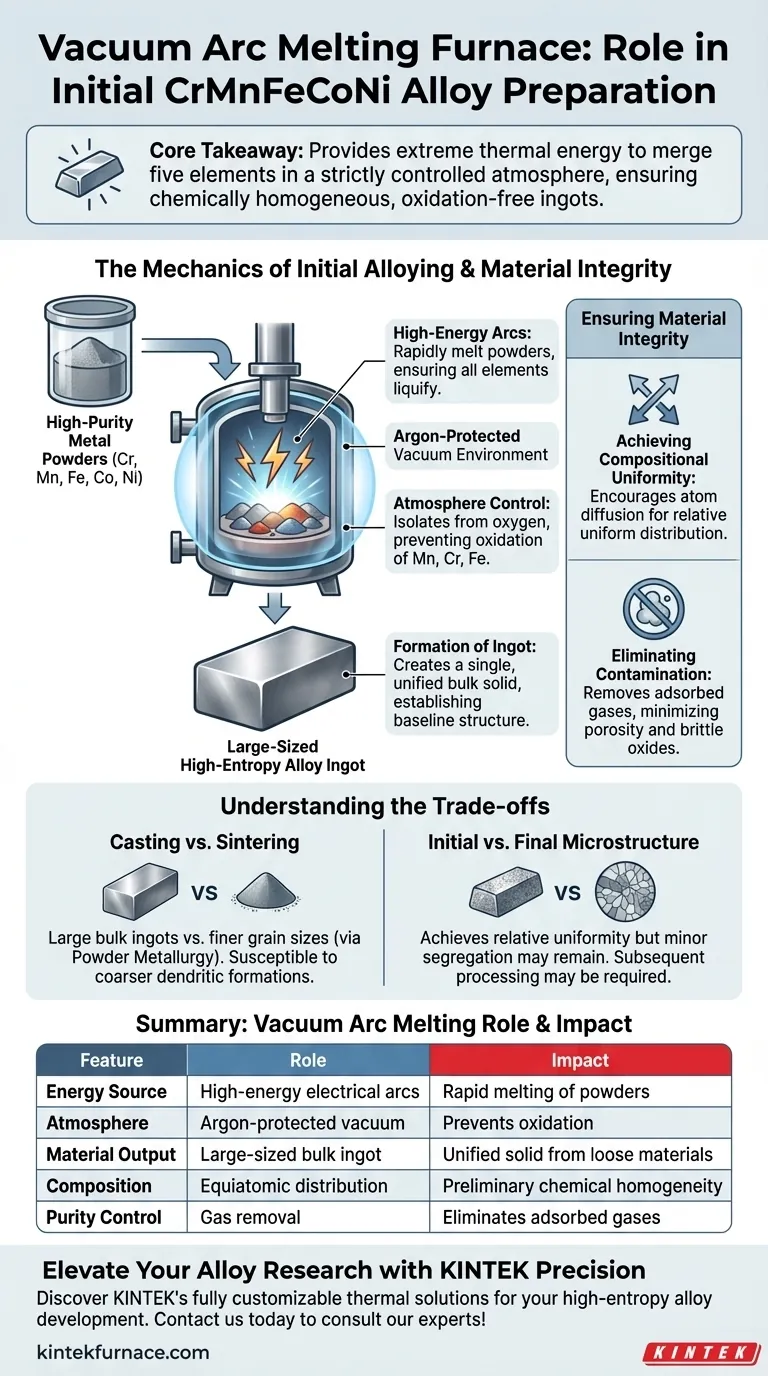

The vacuum arc melting furnace serves as the critical foundational tool for the initial synthesis of CrMnFeCoNi high-entropy alloys. It utilizes high-energy electrical arcs to rapidly melt high-purity metal powders within an argon-protected environment, converting loose raw materials into a single, unified alloy ingot.

Core Takeaway The primary function of this furnace is to provide the extreme thermal energy required to merge five distinct elements while strictly controlling the atmosphere. This ensures the preliminary alloying results in a chemically homogeneous ingot free from the oxidation that compromises material performance.

The Mechanics of Initial Alloying

High-Energy Thermal Processing

The furnace employs high-energy arcs to generate the intense heat necessary to melt the constituent elements.

This is not a gradual heating process; it is a rapid melting mechanism designed to handle high-purity metal powders. The extreme temperature ensures that all five elements, regardless of their individual melting points, are brought to a liquid state to facilitate mixing.

Atmosphere Control and Protection

A defining feature of this process is the argon-protected environment.

The furnace operates under a vacuum or inert gas shield to isolate the molten metal from atmospheric oxygen. This is vital because elements within the CrMnFeCoNi alloy—specifically Manganese (Mn), Chromium (Cr), and Iron (Fe)—are highly susceptible to oxidation at high temperatures.

Formation of the Ingot

The output of this specific furnace is a large-sized high-entropy alloy ingot.

Unlike sintering processes that compact powders, the vacuum arc melting furnace fully liquefies the material to create a bulk solid. This step acts as the "preliminary alloying" phase, establishing the baseline structure for the material.

Ensuring Material Integrity

Achieving Compositional Uniformity

The process is designed to ensure the equiatomic distribution of the five elements.

By maintaining a molten state under high energy, the furnace encourages the diffusion of atoms. This results in a relatively uniform composition distribution throughout the ingot, preventing pockets where one element might dominate.

Eliminating Contamination

The vacuum environment actively removes adsorbed gases from the surface of the raw powders.

If these gases were trapped during the melting process, they would form pores or brittle oxides within the alloy. The furnace's atmosphere control minimizes this risk, ensuring the final ingot maintains high purity and structural density.

Understanding the Trade-offs

Casting vs. Sintering Characteristics

While vacuum arc melting excels at producing large bulk ingots, it is fundamentally a casting process.

This means the material inevitably undergoes solidification from a liquid state. Consequently, the alloy may be susceptible to casting-specific issues, such as coarser dendritic formations, compared to alloys produced via powder metallurgy (like vacuum hot pressing), which typically achieve finer grain sizes.

Initial Homogeneity vs. Final Microstructure

The furnace provides preliminary alloying, but it may not be the final step for all applications.

While it achieves relative uniformity, the rapid solidification of a large ingot can still lead to minor compositional segregation. Subsequent heat treatments or processing may be required to refine the microstructure further.

Making the Right Choice for Your Goal

To determine if vacuum arc melting is the correct initial step for your specific CrMnFeCoNi application, consider the following:

- If your primary focus is producing large-scale bulk material: Use vacuum arc melting to create substantial ingots with a unified chemical composition.

- If your primary focus is avoiding dendritic structures: Consider a powder metallurgy route (like vacuum hot pressing) to achieve finer grain sizes and superior compressive strength directly from powder.

- If your primary focus is purity: Rely on the vacuum arc process to effectively effectively remove adsorbed gases and prevent oxidation of volatile elements like Manganese.

In summary, the vacuum arc melting furnace is the definitive tool for converting raw powders into a unified, high-purity ingot, laying the chemical groundwork for the alloy's final properties.

Summary Table:

| Feature | Vacuum Arc Melting Role | Impact on CrMnFeCoNi Alloy |

|---|---|---|

| Energy Source | High-energy electrical arcs | Facilitates rapid melting of high-purity metal powders |

| Atmosphere | Argon-protected vacuum | Prevents oxidation of Mn, Cr, and Fe elements |

| Material Output | Large-sized bulk ingot | Creates a single, unified solid from loose materials |

| Composition | Equiatomic distribution | Ensures preliminary chemical homogeneity and diffusion |

| Purity Control | Gas removal | Eliminates adsorbed gases to prevent internal porosity |

Elevate Your Alloy Research with KINTEK Precision

Are you looking to achieve perfect compositional uniformity in your high-entropy alloy development? KINTEK provides industry-leading thermal solutions designed for the most demanding material science applications.

Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces. Whether you are performing preliminary casting or advanced powder metallurgy, our systems are fully customizable to meet your unique research needs.

Ready to optimize your synthesis process? Contact us today to consult with our experts and discover the KINTEK advantage.

Visual Guide

References

- Ajay Talbot, Yu Zou. Laser Remelting of a CrMnFeCoNi High‐Entropy Alloy: Effect of Energy Density on Elemental Segregation. DOI: 10.1002/adem.202501194

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- How does the control system of an induction melting furnace enhance operation? Boost Efficiency and Precision in Metal Melting

- What are the advantages of induction heating? Achieve Fast, Precise, and Efficient Industrial Heating

- Why is excess Lanthanum required in La(Fe,Si)13 alloy melting? Overcome Burn-off for Peak Magnetocaloric Performance

- How do induction furnaces contribute to cost savings in the long term? Unlock Long-Term Efficiency and ROI

- What is the use of an induction melting furnace? Achieve Fast, Clean, and Precise Metal Melting

- What makes channel induction furnaces energy efficient? Achieve High-Volume, Low-Cost Metal Melting

- What are the advantages of vacuum induction melting and casting (VIM&C) over VIM? Achieve Superior Metallurgical Quality and Efficiency

- What is the role of vacuum arc melting equipment in the preparation of Ti-33Al based alloy button ingots?