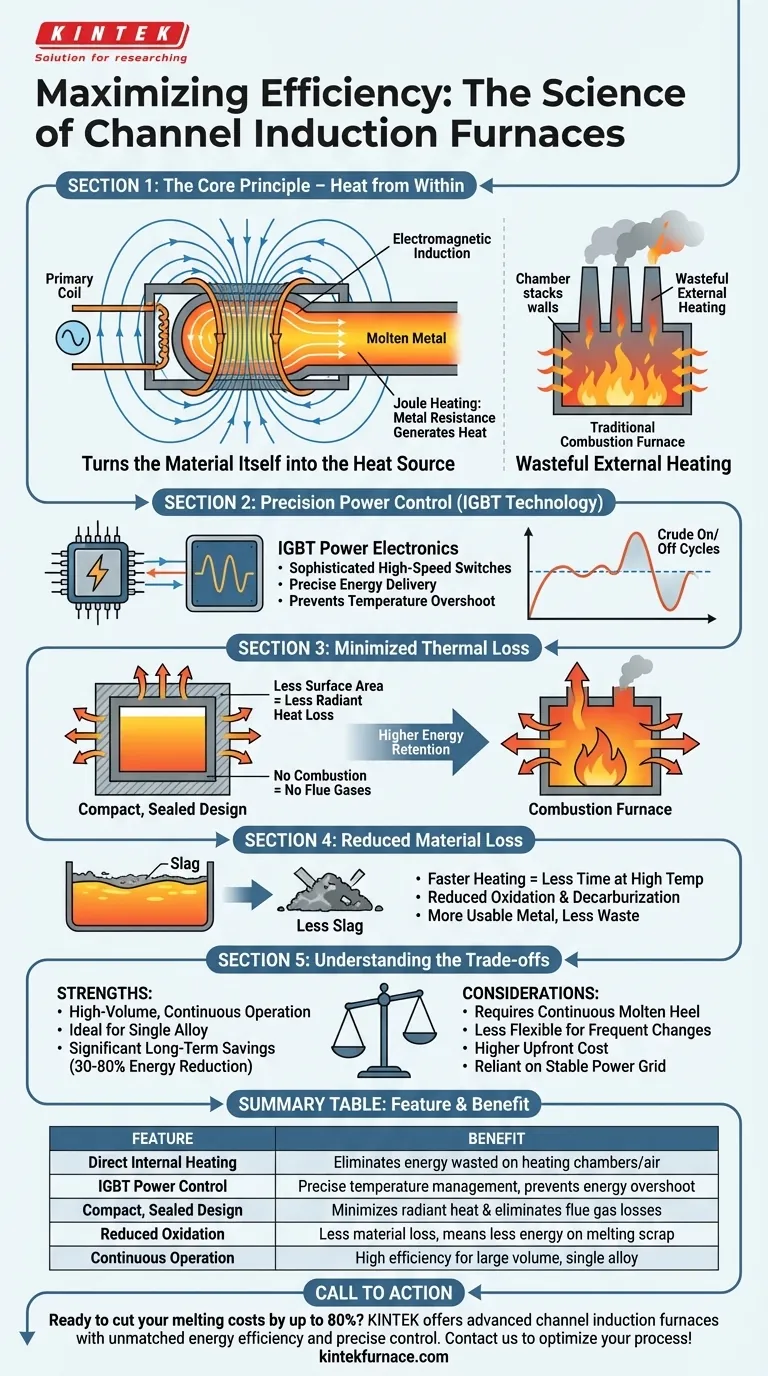

At their core, channel induction furnaces achieve high energy efficiency by using electromagnetic induction to heat the metal directly from within. This method is fundamentally more efficient than traditional furnaces that heat an entire chamber. Key contributing factors include advanced power controls using IGBT technology and a compact design that minimizes thermal loss to the surrounding environment.

The defining advantage of a channel induction furnace is that it turns the material itself into the source of heat. By eliminating the need to heat a container, the air, or fuel byproducts, it radically reduces the energy wasted during the melting and holding process.

The Principles of Induction Efficiency

The efficiency of a channel furnace is not a single feature but the result of several interconnected engineering principles. Understanding these principles is key to evaluating its suitability for your specific application.

The Core Mechanism: Direct Internal Heating

An alternating current is passed through a primary coil, which creates a strong magnetic field. This field induces a much larger secondary current directly within the closed loop or "channel" of molten metal. The metal's natural electrical resistance causes it to heat up rapidly—a process known as Joule heating.

This is fundamentally different from a combustion furnace, which wastes enormous energy heating the furnace walls and atmosphere, with only a fraction of that heat transferring to the metal.

Power Electronics: IGBT Precision Control

Modern furnaces use Insulated-Gate Bipolar Transistor (IGBT) technology. These are sophisticated, high-speed power switches that allow for precise control over the frequency and amount of power delivered to the coil.

This precise control prevents overshooting the target temperature and ensures energy is only consumed when needed to melt or maintain heat, eliminating the waste associated with crude on/off cycles.

Design Advantage: Minimal Thermal Loss

Channel furnaces are inherently compact. This smaller physical footprint means less surface area, which directly translates to less radiant heat loss into the surrounding facility.

Furthermore, because there is no combustion, there are no flue gases. This completely eliminates the significant heat loss that occurs through the exhaust stacks of fuel-fired furnaces.

Process Benefit: Reduced Material Loss

The speed and precision of induction heating minimize the time the metal is held at a high temperature. This results in significantly less oxidation and decarburization.

Less metal is lost to slag, which is a direct efficiency gain. You are not wasting energy melting material that will ultimately be discarded.

Understanding the Trade-offs

No technology is a universal solution. The high efficiency of channel induction furnaces comes with specific operational considerations.

High-Volume, Continuous Operation

The "channel" of a channel furnace must remain filled with molten metal to complete the electrical circuit. This makes them exceptionally efficient for holding large volumes of a single alloy and for high-throughput, continuous or semi-continuous casting operations.

They are, however, less flexible than coreless induction furnaces for applications requiring frequent cold starts or rapid changes between different alloys.

Upfront Cost vs. Lifetime Savings

Induction furnaces typically involve a higher initial capital investment compared to traditional combustion furnaces.

However, the operational savings are significant. An energy reduction of 30–80% compared to cupola or reverberatory furnaces, combined with lower material loss and the elimination of fuel costs, often results in a much lower total cost of ownership.

Reliance on Electrical Infrastructure

The efficiency of the furnace is entirely dependent on a stable and robust electrical supply. Any disruptions to the power grid will directly halt production, whereas some combustion furnaces may have on-site fuel storage as a buffer.

Making the Right Choice for Your Goal

To determine if a channel induction furnace is the correct choice, align its strengths with your primary operational objective.

- If your primary focus is lowering operational costs: The dramatic energy savings, zero fuel consumption, and reduced metal loss make this a leading option for long-term financial performance.

- If your primary focus is high-volume production: The furnace's suitability for continuous melting and holding of a single alloy is ideal for dedicated, high-throughput foundries and die-casting operations.

- If your primary focus is environmental performance: The elimination of combustion byproducts and a smaller carbon footprint due to higher energy efficiency are defining advantages.

Ultimately, choosing the right furnace technology depends on a clear understanding of how its core principles match your production needs.

Summary Table:

| Feature | Benefit |

|---|---|

| Direct Internal Heating (Joule Effect) | Eliminates energy wasted on heating chambers or air |

| IGBT Power Control | Precise temperature management prevents energy overshoot |

| Compact, Sealed Design | Minimizes radiant heat loss and eliminates flue gas losses |

| Reduced Oxidation | Less material loss means less energy wasted on melting scrap |

| Ideal for Continuous Operation | High efficiency in holding and melting large volumes of one alloy |

Ready to cut your melting costs by up to 80%? KINTEK’s advanced channel induction furnaces leverage our in-house R&D and manufacturing expertise to deliver unmatched energy efficiency, precise temperature control, and reduced material loss. Whether you need a standard solution or a fully customized system for high-volume production, our team is here to help. Contact us today to discuss how we can optimize your melting process!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency