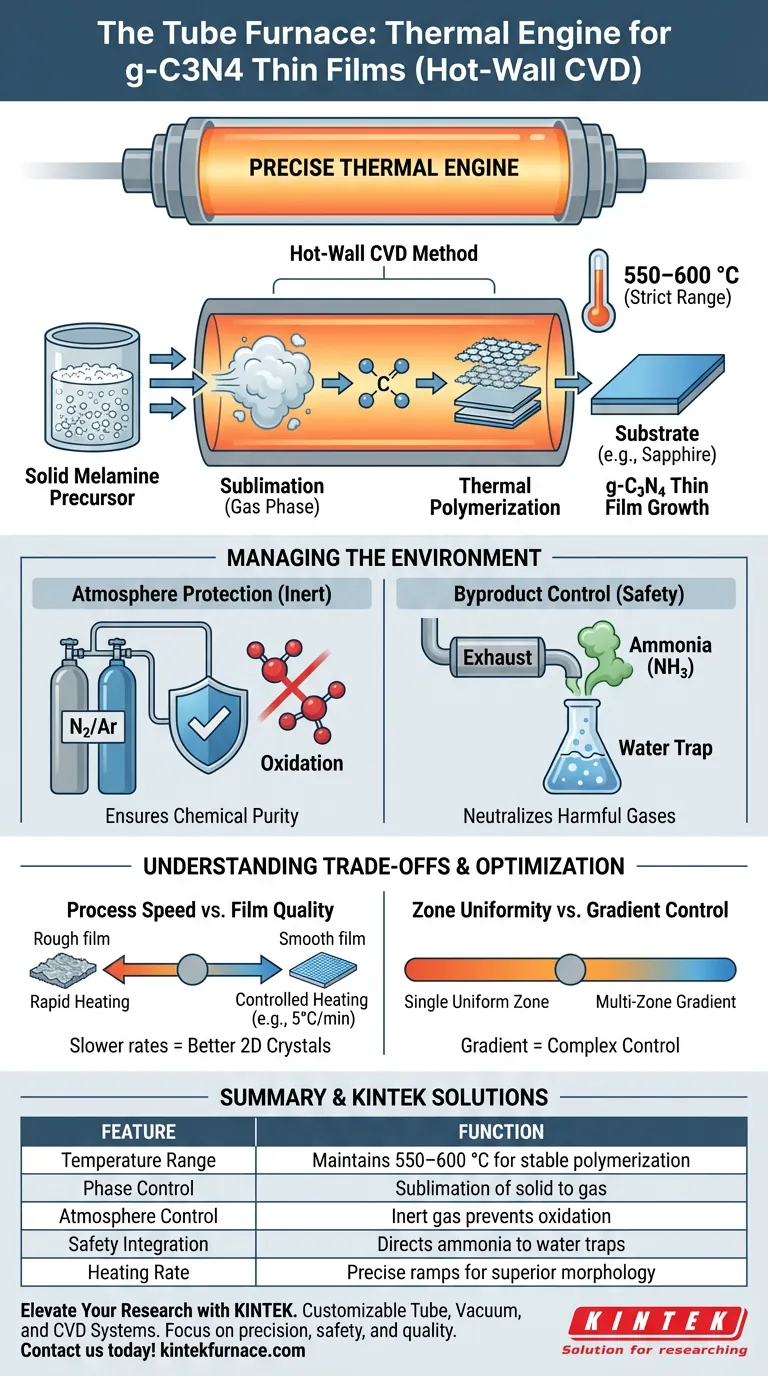

The tube furnace serves as the precise thermal engine required to synthesize layered carbon nitride (g-C3N4) thin films. In the hot-wall Chemical Vapor Deposition (CVD) method, its primary function is to create a stable, high-temperature environment that converts solid melamine precursor into a vapor and drives its subsequent polymerization onto a substrate.

Core Takeaway: The tube furnace acts as a dual-function reactor, simultaneously controlling the phase transition of precursor materials and the kinetics of film growth. By maintaining a strict temperature range (typically 550–600 °C), it ensures the uniform thermal polymerization necessary to produce high-quality g-C3N4 thin films on substrates like sapphire.

The Mechanics of Thermal Control

Initiating Precursor Phase Transition

The process begins with the furnace heating the solid melamine precursor powder. The furnace must provide sufficient thermal energy to sublime the powder, effectively turning it from a solid into a gas phase.

This gas-phase generation is the critical first step in transport-based deposition. Without precise heating, the precursor would remain solid or decompose unevenly.

Driving Thermal Polymerization

Once the precursor is in the vapor phase, the furnace facilitates the chemical reaction known as thermal polymerization. This reaction reforms the molecular structure of the melamine into the layered graphitic carbon nitride structure.

The heat supplied by the furnace provides the activation energy required for these molecules to bond and assemble onto the substrate surface.

Maintaining Reaction Zone Stability

The hot-wall CVD method relies on a uniform temperature profile. The tube furnace is responsible for maintaining a constant temperature in the reaction zone, specifically between 550 and 600 °C.

Fluctuations outside this range can lead to poor film quality or incomplete polymerization. The "hot-wall" nature ensures that the reactor walls are heated, minimizing cold spots that could cause premature condensation of the precursor.

Managing the Reaction Environment

Controlling Byproduct Emissions

The thermal decomposition of melamine inevitably produces waste gases, specifically ammonia. The tube furnace setup plays a role in safety by directing these gases toward the exhaust system.

A water trap device is typically connected to the furnace's exhaust end. This absorbs and neutralizes the ammonia, preventing the release of harmful fumes into the laboratory atmosphere.

Atmosphere Protection

While the primary focus is heat, the tube furnace also provides a sealed environment for atmosphere control. It allows for the introduction of inert gases (typically Nitrogen or Argon) to act as carriers.

This inert atmosphere prevents the oxidation of the carbon materials at high temperatures, ensuring the chemical purity of the final g-C3N4 film.

Understanding the Trade-offs

Process Speed vs. Film Quality

A tube furnace allows for the adjustment of heating rates (e.g., 5 °C per minute). Rapid heating might accelerate the process but can lead to uncontrolled sublimation and rough film morphology.

Slower, controlled heating rates facilitate better organization of the molecular structure, resulting in higher quality 2D crystals, but increase the overall fabrication time.

Zone Uniformity vs. Gradient Control

For simple deposition, a single uniform temperature zone is effective. However, complex transport mechanisms may benefit from a multi-zone furnace.

A multi-zone setup can create a temperature gradient, volatilizing precursors in an upstream zone and depositing them in a cooler downstream zone. While this offers more control over nucleation, it adds complexity to the parameter optimization.

Making the Right Choice for Your Goal

To maximize the effectiveness of your CVD process, align your furnace settings with your specific objectives:

- If your primary focus is Film Homogeneity: Prioritize a furnace with a long, stable constant temperature zone (550–600 °C) to ensure uniform polymerization across the substrate.

- If your primary focus is Laboratory Safety: Ensure your furnace exhaust is strictly coupled with a functional water trap to neutralize the significant ammonia byproducts released during melamine decomposition.

- If your primary focus is Crystal Quality: Utilize a programmed heating ramp (e.g., 5 °C/min) rather than rapid heating to allow for orderly molecular assembly and reduced defects.

Success in g-C3N4 synthesis relies not just on reaching high temperatures, but on the precise stability of that thermal environment.

Summary Table:

| Feature | Function in g-C3N4 CVD Synthesis |

|---|---|

| Temperature Range | Maintains 550–600 °C for stable thermal polymerization |

| Phase Control | Facilitates sublimation of solid melamine into gas phase |

| Atmosphere Control | Uses inert gas (N2/Ar) to prevent oxidation and ensure purity |

| Safety Integration | Directs ammonia byproducts to water traps for neutralization |

| Heating Rate | Precise ramps (e.g., 5 °C/min) for superior 2D crystal morphology |

Elevate Your Thin Film Research with KINTEK

Precision is the backbone of high-quality g-C3N4 thin film synthesis. At KINTEK, we understand that stable thermal environments and controlled atmospheres are non-negotiable for successful CVD processes.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Tube, Vacuum, and CVD systems, along with other lab high-temp furnaces—all fully customizable to meet your unique research needs. Whether you are optimizing crystal quality or ensuring laboratory safety, our equipment provides the reliability you require.

Ready to achieve superior film homogeneity? Contact our technical experts today to find the perfect furnace solution for your lab!

Visual Guide

References

- Kota Higuchi, Yoshio Hashimoto. Layered carbon nitride films deposited under an oxygen-containing atmosphere and their electronic properties. DOI: 10.1063/5.0193419

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the technical value of using an industrial-grade tube furnace for titania nanotubes? Enhance Crystal Performance

- What are the key design features of a split tube furnace? Unlock Superior Access for Complex Experiments

- What are the specialized functions of a high-temperature tube furnace in the final sintering of proton ceramics?

- What are the controlled atmosphere capabilities of a tube furnace? Unlock Precise Gas Control for Your Lab

- What are the functional advantages of utilizing a high-temperature vertical tube quartz reactor for MoS2/rGO pyrolysis?

- What is the primary function of a high-temperature tube furnace in h-BN preparation? Achieve Clean Surface Activation

- Why is a tube furnace with nitrogen flow necessary for BaFe2-xCoxFe16O27 ceramics? Master Iron Valence Engineering

- What are common applications of Tube Furnaces? Unlock Precision in Material Synthesis and Heat Treatment