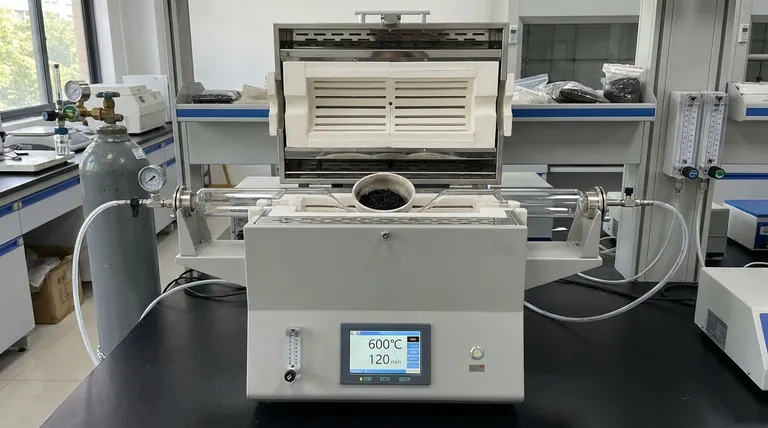

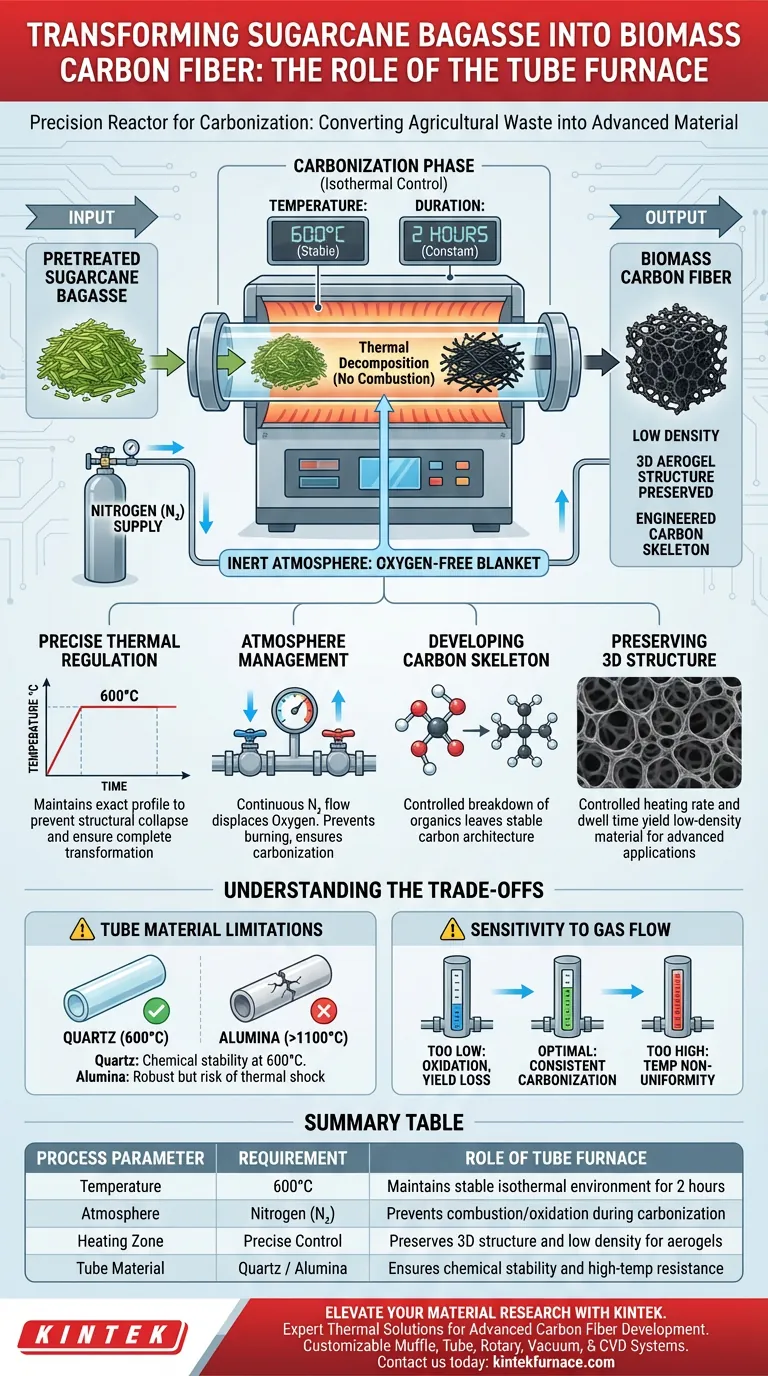

The tube furnace functions as a precision reactor for the carbonization phase, specifically converting chemically pretreated sugarcane bagasse into biomass carbon fiber. By maintaining a constant temperature of 600°C for two hours within a protective nitrogen atmosphere, the furnace facilitates the thermal decomposition of the biomass without combustion.

The tube furnace enables the successful transition from organic plant matter to engineered carbon material. Its primary role is to provide a stable, oxygen-free thermal environment that preserves a low-density, three-dimensional structure essential for aerogel frameworks.

Creating the Carbonization Environment

Precise Thermal Regulation

The fundamental role of the tube furnace in this process is isothermal control.

For sugarcane bagasse conversion, the furnace must hold the sample at exactly 600°C for a duration of two hours. This specific thermal profile ensures the complete transformation of the pretreated fiber into carbon while preventing the structural collapse that could occur at excessive temperatures.

Atmosphere Management

A tube furnace distinguishes itself from a standard oven through its ability to control the reaction atmosphere.

In this application, the furnace tube—typically made of high-temperature-resistant quartz or alumina—is sealed to create an anaerobic environment. A continuous flow of nitrogen gas is introduced to displace oxygen. This "inert blanket" is critical; without it, the high temperatures would simply burn the sugarcane bagasse to ash rather than carbonizing it into fiber.

Material Transformation and Outcome

Developing the Carbon Skeleton

Inside the furnace, the bagasse undergoes thermochemical changes, such as dehydration and decarbonization.

Because the environment is strictly controlled, the organic components break down predictably. This leaves behind a stable biomass carbon fiber that retains a specific architecture.

Preserving Three-Dimensional Structure

The ultimate goal of using a tube furnace is to produce a material suitable for advanced applications, such as aerogel construction.

The controlled heating rate and stable dwell time result in a final product with low density and a preserved three-dimensional structure. This structural integrity is the physical foundation required for subsequent activation steps or use as a structural framework.

Understanding the Trade-offs

Tube Material Limitations

While tube furnaces offer precision, the core component—the furnace tube—has physical limits.

Quartz tubes offer excellent chemical stability and are ideal for the 600°C range required for this bagasse process. However, if your research expands to higher temperatures (above 1100°C), quartz may degrade, necessitating a switch to alumina, which is more robust but susceptible to thermal shock.

Sensitivity to Gas Flow

The success of the carbonization relies heavily on the consistency of the nitrogen flow.

If the flow rate is too low, residual oxygen may remain, leading to partial combustion and loss of yield. Conversely, an excessively high flow rate can disturb the temperature uniformity within the heating zone, leading to inconsistent carbonization across the sample batch.

Making the Right Choice for Your Goal

To maximize the quality of biomass carbon fiber derived from sugarcane bagasse, apply these principles:

- If your primary focus is Structural Integrity: Ensure your furnace can maintain a strict 600°C profile to preserve the three-dimensional framework required for aerogels.

- If your primary focus is Chemical Purity: Verify that your nitrogen gas supply is free of contaminants and that the furnace seals are airtight to prevent oxidation during the two-hour dwell time.

The tube furnace is not merely a heating element; it is the vessel that orchestrates the delicate chemistry required to turn agricultural waste into advanced engineering material.

Summary Table:

| Process Parameter | Requirement | Role of Tube Furnace |

|---|---|---|

| Temperature | 600°C | Maintains stable isothermal environment for 2 hours |

| Atmosphere | Nitrogen (N₂) | Prevents combustion/oxidation during carbonization |

| Heating Zone | Precise Control | Preserves 3D structure and low density for aerogels |

| Tube Material | Quartz / Alumina | Ensures chemical stability and high-temperature resistance |

Elevate Your Material Research with KINTEK

Transform agricultural waste into high-performance biomass carbon fibers with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and precision manufacturing, KINTEK offers a wide range of Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific isothermal and atmospheric requirements.

Whether you are developing aerogel frameworks or advanced carbon skeletons, our furnaces provide the stability and control your research demands. Contact us today to find the perfect high-temp furnace for your laboratory!

Visual Guide

References

- Mengxuan Zhu, Yong Jiang. MXene/carbonized bagasse fiber aerogel thermal insulation material. DOI: 10.1063/5.0194659

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the technical requirements for a Tube Furnace in nitrogen-doping? Essential Specs for Metal Oxide Processing

- How does a laboratory horizontal tube furnace establish a controlled environment? Precision Corrosion Testing Guide

- What advantages do tube furnaces offer for research applications? Unlock Precision in Atmosphere and Temperature Control

- What is sintering, and how is it performed in horizontal furnaces? Unlock Precision in Powder Processing

- What is the recommended procedure for using a vacuum tube type experimental furnace with a specific atmosphere? Master Precise Control for Your Experiments

- What function does a high-purity quartz tube serve during the vapor-phase synthesis of MoS2? Key Roles & Benefits

- What are the types of Tube Furnaces based on tube shape? Choose Between Solid and Split for Your Lab

- How does the work process of a quartz tube furnace typically proceed? Master Precision Heating for Advanced Materials