At their core, tube furnaces offer two primary advantages for research applications: unparalleled control over the sample's atmosphere and exceptional temperature precision. Their cylindrical chamber design allows for a sealed environment, making it possible to introduce specific gases or create a vacuum, which is critical for synthesizing advanced materials and preventing unwanted chemical reactions at high temperatures.

The decision to use a tube furnace is a strategic choice for process integrity. You are trading the large-volume capacity of other furnace types for superior control over the atmospheric conditions and temperature profile of your experiment.

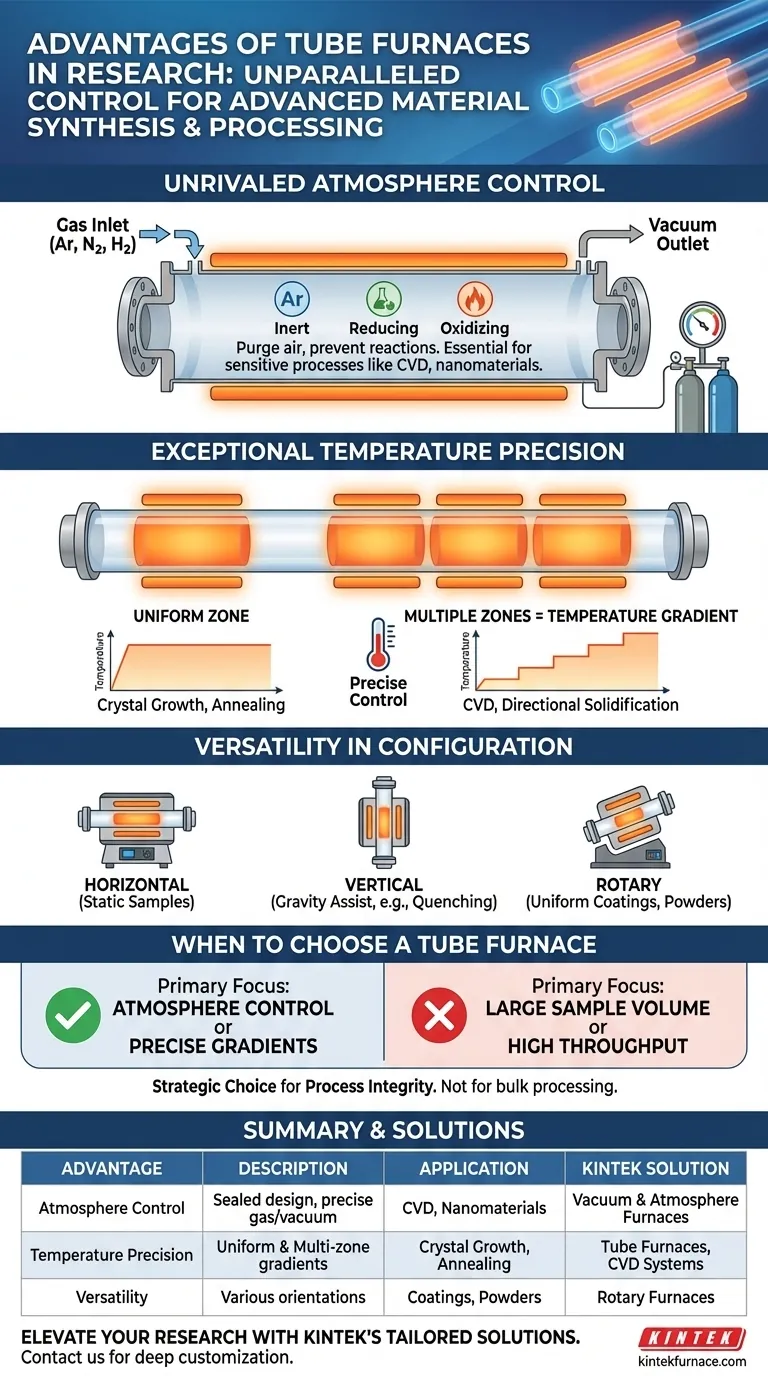

The Defining Advantage: Unrivaled Atmosphere Control

The most significant reason researchers choose a tube furnace is the ability to dictate the gaseous environment surrounding a sample. Unlike box furnaces, which are difficult to seal, the tubular design is inherently suited for containment.

How Sealed Tubes Enable Precision

A tube furnace works by heating a cylindrical tube, typically made of ceramic or quartz, that contains the sample. The ends of this tube can be sealed with flanges that include ports for gas inlets, outlets, and vacuum pumps.

This design allows you to completely purge the ambient air (specifically oxygen and moisture) and backfill the chamber with a precise, controlled atmosphere.

Inert, Reducing, and Oxidizing Environments

This level of control enables a wide range of sensitive processes. You can create an inert atmosphere using gases like argon or nitrogen to prevent oxidation, a reducing atmosphere with hydrogen for chemical reduction, or a controlled oxidizing environment.

This capability is essential for applications like semiconductor processing, inorganic compound synthesis, and creating nanomaterials like graphene, where atmospheric purity directly impacts the final product's quality.

Precision Beyond Atmosphere: Temperature Control

While atmosphere is key, tube furnaces also provide a high degree of thermal precision. The heating elements surround the tube, creating a highly uniform temperature zone in the center.

Achieving Temperature Uniformity

The cylindrical geometry of the heating chamber promotes even heat distribution around the sample. This temperature uniformity is critical for processes like crystal growth and annealing, where even minor temperature deviations can ruin an experiment.

The Power of Multiple Heating Zones

Many advanced tube furnaces feature multiple, independently controlled heating zones. This allows a researcher to create a specific temperature gradient along the length of the tube.

This feature is not just for improving uniformity; it is a powerful tool for processes like chemical vapor deposition (CVD) and directional solidification, where different temperature stages are required within the same process.

Versatility in Application and Configuration

Tube furnaces are not a one-size-fits-all solution. Their adaptability in form and function makes them suitable for a wide array of specialized research tasks.

Horizontal vs. Vertical Orientations

Furnaces are available in horizontal and vertical configurations. Horizontal setups are common for processing static samples, while vertical orientations are often preferred for crystal growth or experiments where gravity can assist in the process, such as drop-down quenching.

Advanced Rotary Models

For applications like applying uniform coatings (CVD) or ensuring all particles of a powder are treated equally, rotary tube furnaces are used. These models continuously rotate the tube, tumbling the sample to ensure every surface is uniformly exposed to both the heat and the process atmosphere.

Understanding the Trade-offs

While powerful, tube furnaces are not the ideal solution for every heating application. Objectivity requires acknowledging their limitations.

Sample Volume and Throughput

The most significant trade-off is sample volume. By design, the diameter of the tube limits the size and quantity of the material you can process at one time.

If your research involves heat-treating large components or a high volume of samples where atmosphere control is not the primary concern, a larger box furnace is often a more practical choice.

Complexity and Cost

Achieving a perfectly sealed, controlled atmosphere adds complexity. It requires vacuum pumps, gas flow controllers, and careful sealing procedures. This can make the setup and operation more involved and potentially more expensive than a simple air-atmosphere box furnace.

Making the Right Choice for Your Research

Your specific experimental goal should dictate your choice of equipment. A tube furnace is a specialized tool designed for processes that demand environmental and thermal precision.

- If your primary focus is process atmosphere control: For tasks like synthesis, purification, or CVD that require inert, reducing, or specific gas environments, the tube furnace is the definitive choice.

- If your primary focus is creating precise temperature gradients: A multi-zone tube furnace is the only practical way to achieve this for specialized growth or deposition processes.

- If your primary focus is processing large samples or high throughput: A box furnace will likely be more efficient, provided the lack of atmospheric control is acceptable for your process.

Ultimately, selecting a tube furnace is an investment in process control and experimental repeatability.

Summary Table:

| Advantage | Description |

|---|---|

| Atmosphere Control | Sealed tube design allows for inert, reducing, or oxidizing gas environments, essential for sensitive processes like CVD and nanomaterial synthesis. |

| Temperature Precision | Uniform heating and multi-zone control enable exact thermal profiles for crystal growth, annealing, and gradient-dependent experiments. |

| Versatility | Available in horizontal, vertical, and rotary configurations to suit various research needs, from static samples to uniform coatings. |

| Limitations | Limited sample volume and higher complexity/cost compared to box furnaces; ideal for precision over throughput. |

Elevate your research with KINTEK's advanced tube furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems. Our product line includes Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how our expertise can enhance your process control and experimental repeatability!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency