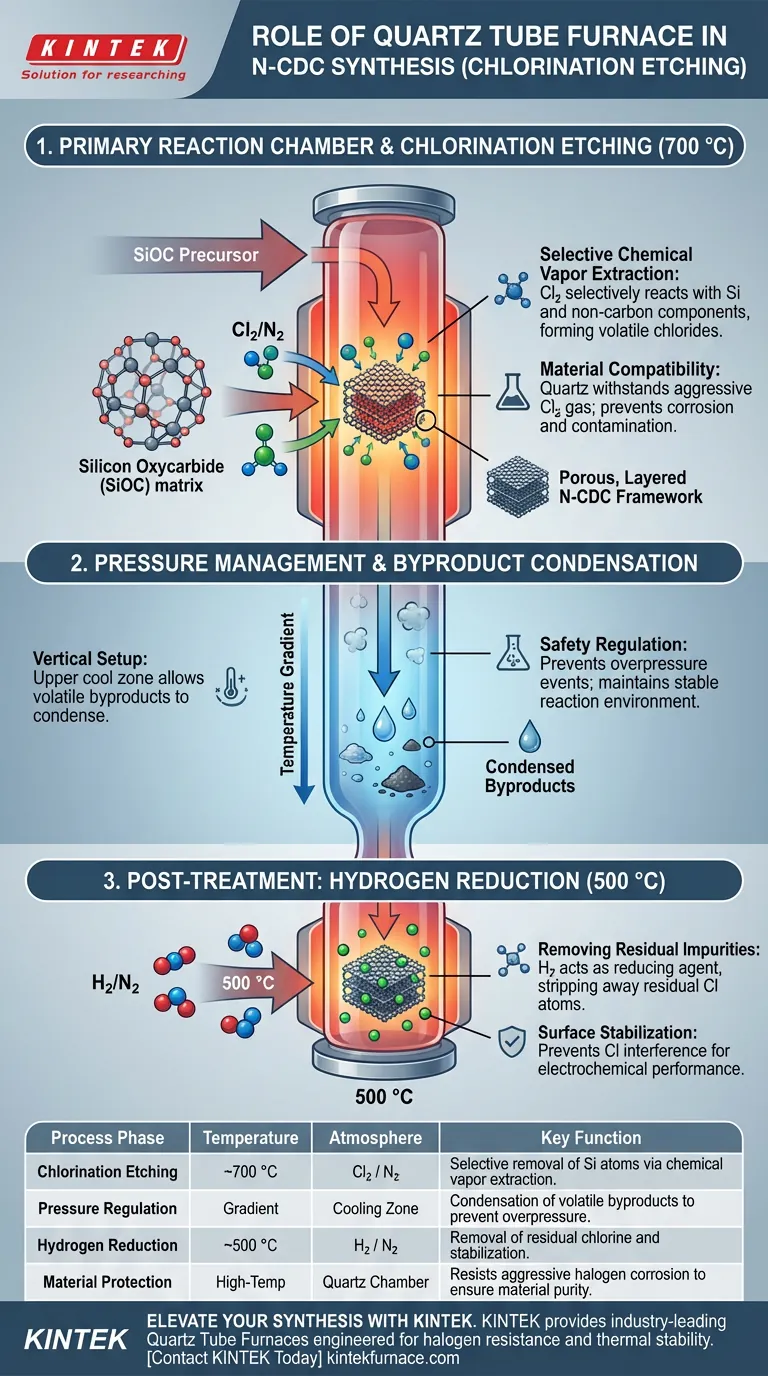

The quartz tube furnace acts as the primary reaction chamber responsible for synthesizing Nitrogen-doped Carbide-Derived Carbon (N-CDC) materials. It maintains a precise temperature environment, typically around 700 °C, while facilitating the flow of a corrosive chlorine gas mixture (Cl2/N2) needed to strip silicon atoms from the precursor matrix. The quartz material is selected specifically for its ability to withstand this aggressive halogen atmosphere without degrading, ensuring the purity of the final carbon structure.

By providing a chemically inert and thermally stable environment, the quartz tube furnace enables the selective removal of non-carbon elements through chemical vapor extraction. This process transforms dense silicon oxycarbide precursors into porous, layered carbon frameworks critical for electrochemical applications.

The Mechanics of Chlorination Etching

Creating the Reaction Environment

The fundamental role of the furnace is to provide a stable thermal zone where chemical synthesis can occur. For N-CDC synthesis, the furnace heats the Silicon Oxycarbide (SiOC) precursor to approximately 700 °C.

Selective Chemical Vapor Extraction

At these elevated temperatures, the furnace facilitates the introduction of chlorine gas. This gas triggers a reaction known as chemical vapor extraction.

During this phase, chlorine selectively reacts with silicon atoms and other non-carbon components within the matrix. This reaction converts these components into volatile chlorides, effectively "etching" them away while leaving the carbon framework intact.

Material Compatibility and Safety

The use of quartz is not arbitrary; it is a functional requirement. The etching process utilizes highly aggressive halogen gases that would corrode standard metal reaction chambers.

Quartz offers the necessary high-temperature corrosion resistance. This ensures the structural integrity of the furnace and prevents foreign contaminants from leaching into the N-CDC material during synthesis.

Process Control and Pressure Management

Managing Internal Pressure

In specific configurations, such as vertical tube setups, the furnace design plays an active role in safety regulation. By positioning the quartz tube so the upper end protrudes outside the heating zone, the system creates a temperature gradient.

Condensation of Byproducts

The bottom of the tube remains in the high-temperature zone to drive the etching reaction. Simultaneously, the cooler upper section allows volatile byproducts to condense.

This separation helps regulate internal tube pressure. By condensing gases back into liquids or solids in the cool zone, the system prevents dangerous overpressure events and maintains a stable reaction environment.

Post-Treatment Capabilities

Removing Residual Impurities

The role of the quartz tube furnace extends beyond the initial etching. After the carbon structure is formed, it is often necessary to treat the material to remove trapped impurities.

Hydrogen Reduction

The furnace is used to heat the N-CDC to 500 °C under a Nitrogen/Hydrogen (N2/H2) atmosphere. The hydrogen acts as a reducing agent, stripping away residual chlorine atoms trapped within the micropores.

This step is vital for stabilizing the surface chemistry of the carbon framework. It prevents chlorine from interfering with the material's future electrochemical performance.

Operational Trade-offs

Handling Aggressive Atmospheres

While quartz is resistant to chlorine, the process involves handling toxic and corrosive gases at high temperatures. Any breach in the quartz tube or seal failure can lead to hazardous leaks.

Thermal Management Limitations

Quartz has excellent thermal shock resistance, but the required temperature gradients (hot zone vs. cold zone) must be carefully managed. If the transition zone is too abrupt or poorly positioned, thermal stress could compromise the tube's integrity over repeated cycles.

Byproduct Accumulation

The condensation method used to control pressure creates a secondary issue: waste accumulation. The condensed volatile byproducts in the cool zone must be regularly cleaned to prevent clogging or cross-contamination in subsequent runs.

Making the Right Choice for Your Goal

To maximize the quality of Nitrogen-doped Carbide-Derived Carbon, you must optimize how the furnace is utilized throughout the entire workflow.

- If your primary focus is Structural Porosity: Ensure the furnace maintains a stable 700 °C temperature to fully drive the chemical vapor extraction of silicon.

- If your primary focus is Electrochemical Stability: Do not skip the secondary annealing step at 500 °C; the removal of residual chlorine is non-negotiable for high-performance applications.

- If your primary focus is Process Safety: Utilize a vertical setup with a defined cool zone to manage internal pressure through byproduct condensation.

Ultimately, the quartz tube furnace is more than a heater; it is the containment vessel that makes precise, subtractive chemical synthesis possible.

Summary Table:

| Process Phase | Temperature | Atmosphere | Key Function |

|---|---|---|---|

| Chlorination Etching | ~700 °C | Cl2 / N2 | Selective removal of Si atoms via chemical vapor extraction. |

| Pressure Regulation | Gradient | Cooling Zone | Condensation of volatile byproducts to prevent overpressure. |

| Hydrogen Reduction | ~500 °C | H2 / N2 | Removal of residual chlorine and stabilization of carbon pores. |

| Material Protection | High-Temp | Quartz Chamber | Resists aggressive halogen corrosion to ensure material purity. |

Elevate Your Material Synthesis with KINTEK

Precise chlorination and etching require equipment that can withstand the most aggressive chemical environments. KINTEK provides industry-leading Quartz Tube Furnaces, specifically engineered for halogen resistance and superior thermal stability. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique Nitrogen-doped Carbide-Derived Carbon (N-CDC) research needs.

Ready to optimize your lab's high-temperature processes? Contact KINTEK Today to Consult an Expert

Visual Guide

References

- Berta Pérez‐Román, Fernando Rubio‐Marcos. Synergistic Effect of Nitrogen Doping and Textural Design on Metal-Free Carbide-Derived Carbon Electrocatalysts for the ORR. DOI: 10.1021/acsami.5c10307

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- How does the heat treatment temperature in a tube furnace influence RPW electrodes? Optimize Carbonization Performance

- How is the atmosphere controlled in a vacuum tube furnace? Achieve Precise Gas Environments for Your Experiments

- What is the function of an industrial tube furnace during the secondary carbonization of biomass? Achieve Precision.

- What factors affect the price of a vacuum tube furnace? Key Drivers and Smart Investment Tips

- What is a tube furnace and where is it commonly used? Discover Precision Heating for Advanced Materials

- What role does a high-temperature tube furnace play in graphite recycling? Restoring Purity and Structure

- What is the role of a tube furnace in the synthesis of porous nitrogen-doped carbon (NC) supports? Maximize Catalytic Performance

- What role do laboratory tube or muffle furnaces play in simulating SCM435 steel behavior? Optimize Material Research