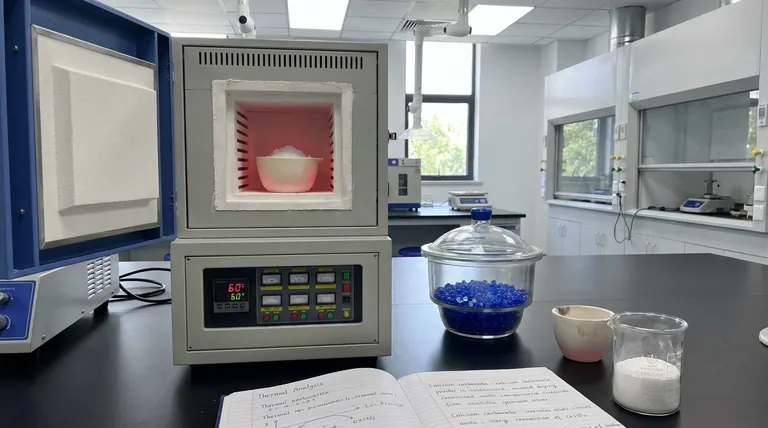

In the context of calcium carbonate thermal decomposition studies, the muffle furnace serves a critical preparatory role focused on moisture elimination rather than chemical reaction. By subjecting the calcium carbonate reagents to a controlled temperature of 60 °C for six hours, the furnace effectively removes physically adsorbed water to isolate the sample material.

The muffle furnace ensures data integrity in thermogravimetric analysis by establishing a stable, moisture-free baseline. Without this drying step, atmospheric moisture could be misinterpreted as sample mass, skewing kinetic calculations and decomposition curves.

The Critical Function of Pretreatment

Removing Adsorbed Water

Calcium carbonate ($CaCO_3$) powder is hygroscopic, meaning it naturally attracts and holds water molecules from the surrounding air.

If left untreated, this physically adsorbed water adds artificial weight to the sample.

The muffle furnace pretreatment heats the powder to 60 °C, a temperature sufficient to evaporate surface moisture without initiating the chemical decomposition of the carbonate itself.

Ensuring Kinetic Accuracy

The primary goal of this pretreatment is to protect the accuracy of subsequent thermogravimetric analysis (TG).

In TG studies, precise mass measurements are vital for calculating decomposition kinetics.

By adhering to a strict protocol of 60 °C for 6 hours, researchers ensure that any mass loss observed during the actual experiment constitutes chemical decomposition, not the evaporation of ambient water.

Why Muffle Furnaces Are Used

Uniform Thermal Distribution

While muffle furnaces are often capable of much higher temperatures—such as the 300 °C used for biomass pyrolysis or the high heat required for ceramic sintering—their value here lies in stability.

The furnace provides a uniform thermal field, ensuring that the entire batch of powder dries evenly.

This prevents "hot spots" that could alter the material or "cold spots" that leave residual moisture.

Controlled Environment

Unlike a standard oven, a laboratory muffle furnace offers precise control over heating rates and temperature maintenance.

This control is essential for reproducibility, ensuring that every sample enters the decomposition study in an identical state.

Understanding the Trade-offs

Temperature Sensitivity

It is crucial to strictly maintain the 60 °C limit during this pretreatment phase.

Setting the furnace temperature too high (e.g., approaching reaction temperatures) could inadvertently begin the decomposition process or alter the crystal structure before the study begins.

Re-adsorption Risks

The benefit of muffle furnace drying is temporary if the sample is mishandled immediately after.

Once removed from the furnace, the dried calcium carbonate will immediately begin re-adsorbing atmospheric moisture.

Samples must be moved directly to the analyzer or stored in a desiccator to maintain the dry baseline achieved by the furnace.

Making the Right Choice for Your Goal

- If your primary focus is Kinetic Data Accuracy: strictly adhere to the 60 °C limit for 6 hours to eliminate moisture interference without altering the chemical composition.

- If your primary focus is Material Synthesis: utilize the furnace's higher temperature capabilities for sintering or calcination, but recognize this fundamentally changes the material rather than just drying it.

Proper use of the muffle furnace converts a variable reagent into a reliable standard for analysis.

Summary Table:

| Feature | Pretreatment Specification | Impact on Analysis |

|---|---|---|

| Target Temp | 60 °C | Prevents premature chemical decomposition |

| Duration | 6 Hours | Ensures total removal of adsorbed water |

| Uniformity | High Thermal Stability | Eliminates cold spots and residual moisture |

| Objective | Moisture Elimination | Establishes a stable mass baseline for TG/DTG |

Maximize the precision of your thermal analysis with KINTEK’s advanced heating solutions. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to meet your unique laboratory requirements. Whether you are drying reagents for kinetic studies or performing high-temperature synthesis, our furnaces deliver the uniform thermal distribution and precise control your research demands. Contact KINTEK today to discover how our high-performance lab furnaces can enhance your experimental accuracy and efficiency.

Visual Guide

References

- Dingxiang Zhuang, Bin Sun. Thermal Decomposition of Calcium Carbonate at Multiple Heating Rates in Different Atmospheres Using the Techniques of TG, DTG, and DSC. DOI: 10.3390/cryst15020108

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What function does a high-temperature muffle furnace serve in ceramic membrane substrate preparation?

- What are some general-purpose uses of a muffle furnace? Essential for High-Purity Material Processing

- What temperature range can muffle furnaces operate at? Find Your Ideal Heat Solution for 800°C to 1800°C

- What are the advantages of a box type electric furnace? Achieve Precise, Safe Thermal Processing

- How is the box furnace's door secured and what safety feature does it have? Ensuring Safe Operation with Robust Design

- How does advanced technology in muffle furnaces improve their performance in pharmaceutical applications? Boost Precision and Purity in Pharma Labs

- What experimental conditions does an industrial high-temperature muffle furnace provide for thermal stress testing?

- Why is a programmable temperature control box furnace required for Bi-2223? Ensure High-Purity Superconductor Synthesis