Advanced technology in muffle furnaces directly translates to greater precision, purity, and reproducibility in pharmaceutical applications. Modern furnaces achieve this through superior insulation for uniform heat distribution, advanced digital controllers for precise temperature management, and a sealed "muffle" chamber that isolates the sample from heating elements and combustion contaminants. This ensures that analytical results, from quality control ashing to materials research, are a true reflection of the sample itself.

The core value of a modern muffle furnace in a pharmaceutical setting isn't just its ability to get hot. It is its engineered capacity to create a perfectly controlled, isolated, and repeatable thermal environment, thereby eliminating critical variables that could compromise sample integrity and the validity of research.

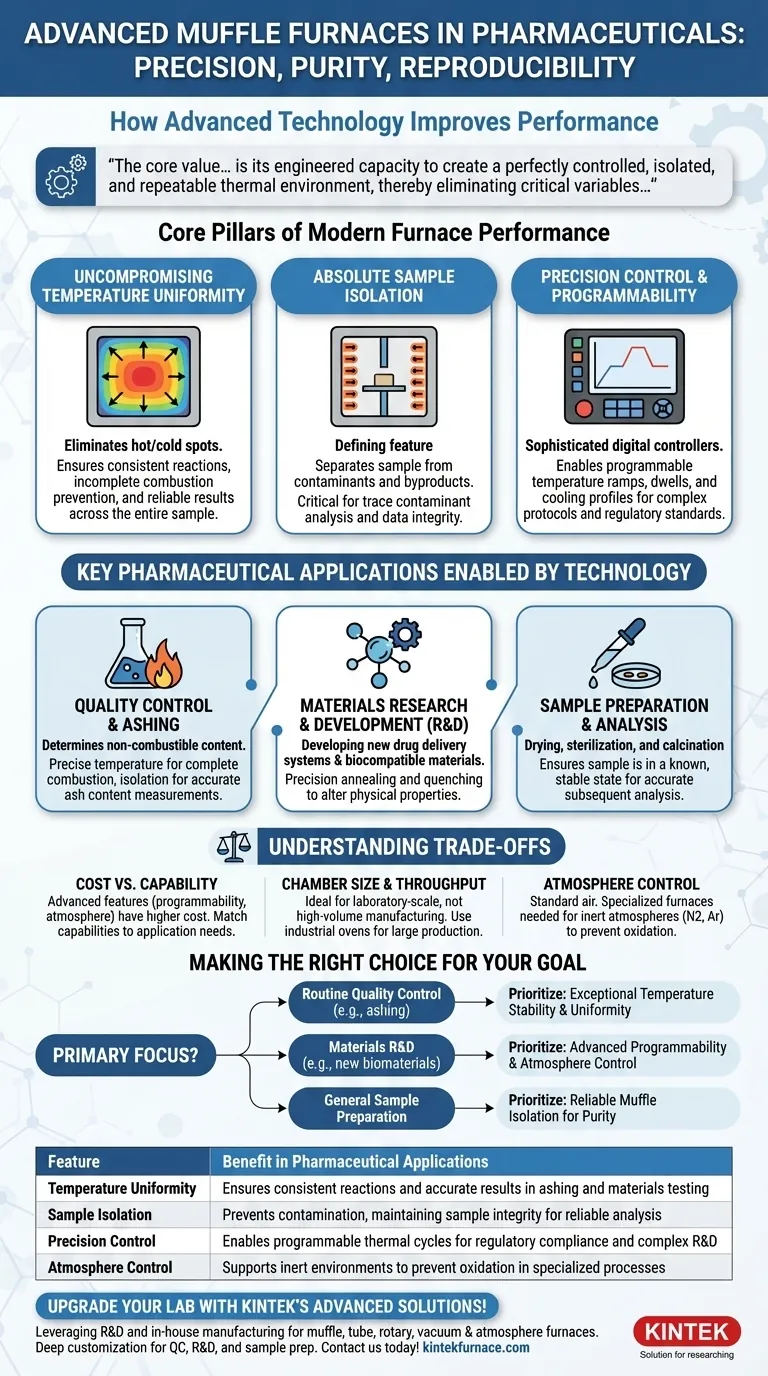

The Core Pillars of Modern Furnace Performance

To understand the impact on pharmaceuticals, we must first look at the key technological advancements that define a modern muffle furnace. These features are not just incremental improvements; they are foundational to ensuring data integrity.

Uncompromising Temperature Uniformity

Advanced insulation materials and strategically placed heating elements work together to eliminate hot and cold spots within the furnace chamber.

This temperature uniformity is critical. When a sample is heated, any variation in temperature across its mass can lead to inconsistent reactions, incomplete combustion during ashing, or skewed results in materials testing. Uniformity guarantees that the entire sample experiences the exact same thermal process.

Absolute Sample Isolation

The defining feature of a muffle furnace is the muffle—an inner chamber that separates the sample from the heating elements and any potential contaminants from combustion.

In the pharmaceutical world, where trace contaminants can invalidate an entire batch or study, this isolation is non-negotiable. It ensures that any changes to the sample are a result of the intended thermal process alone, not a reaction with furnace byproducts.

Precision Control and Programmability

Modern furnaces have moved beyond simple thermostats. They now feature sophisticated digital controllers that allow users to program precise temperature ramps, holds (dwells), and cooling profiles.

This level of control is essential for complex applications like annealing medical device components, calcining specific chemical compounds, or running repeatable quality control protocols that must adhere to strict regulatory standards.

Key Pharmaceutical Applications Enabled by Technology

These technological pillars directly enable critical processes throughout the pharmaceutical lifecycle, from initial research to final product verification.

Quality Control and Ashing

A primary use of muffle furnaces is for ashing, a process that burns off all organic content to determine the non-combustible, inorganic content of a sample. This is a fundamental quality control test for raw materials and finished products.

Precise temperature control ensures complete and efficient combustion, while sample isolation prevents contamination, leading to highly accurate and repeatable ash content measurements.

Materials Research and Development (R&D)

Muffle furnaces are indispensable for creating the next generation of medical products. Researchers use them for developing new drug delivery systems and creating novel biocompatible materials.

Processes like annealing and quenching are used to alter the physical properties of materials, enhancing their strength, durability, or performance for use in drug formulations or advanced medical devices. The furnace's precision makes this experimental work possible.

Sample Preparation and Analysis

Many analytical techniques require samples to be prepared in a specific way. Muffle furnaces are used for drying, sterilization, and calcination to ensure a sample is in a known and stable state before further testing.

This pretreatment step removes moisture, organic compounds, or other volatile substances, guaranteeing that subsequent analysis is accurate and not skewed by unwanted variables.

Understanding the Trade-offs

While advanced muffle furnaces offer significant benefits, it is crucial to understand their context and limitations to make an informed decision.

Cost vs. Capability

Advanced features come at a price. A furnace with highly sophisticated programmability, a larger chamber, or the ability to handle inert gas atmospheres will have a significantly higher cost. It is essential to match the furnace's capabilities to the specific application to avoid over-investing in features that are not required.

Chamber Size and Throughput

Muffle furnaces are ideal for laboratory-scale thermal processing of small workpieces or batches. They are not designed for high-volume manufacturing. For large-scale production needs, industrial ovens or kilns are the appropriate tools.

Atmosphere Control

A standard muffle furnace operates with an air atmosphere. While this is suitable for the majority of applications like ashing and drying, certain materials science processes require an inert atmosphere (e.g., nitrogen or argon) to prevent oxidation. Furnaces with this capability are specialized and more complex.

Making the Right Choice for Your Goal

Selecting the correct muffle furnace requires a clear understanding of your primary objective. Different applications place different demands on the equipment.

- If your primary focus is routine Quality Control (e.g., ashing): Prioritize a furnace with documented, exceptional temperature stability and uniformity to ensure consistent and compliant results.

- If your primary focus is Materials R&D (e.g., creating new biomaterials): Choose a furnace with advanced programmability for complex thermal cycles and consider one with atmosphere control if oxidation is a concern.

- If your primary focus is general sample preparation: A reliable furnace that guarantees sample purity through excellent muffle isolation is critical; advanced programming may be a secondary concern.

Ultimately, choosing the right muffle furnace is a direct investment in the integrity and reliability of your pharmaceutical data.

Summary Table:

| Feature | Benefit in Pharmaceutical Applications |

|---|---|

| Temperature Uniformity | Ensures consistent reactions and accurate results in ashing and materials testing |

| Sample Isolation | Prevents contamination, maintaining sample integrity for reliable analysis |

| Precision Control | Enables programmable thermal cycles for regulatory compliance and complex R&D |

| Atmosphere Control | Supports inert environments to prevent oxidation in specialized processes |

Upgrade your pharmaceutical laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide muffle, tube, rotary, vacuum & atmosphere furnaces, and CVD/PECVD systems tailored to your needs. Our deep customization capabilities ensure precise performance for applications like quality control ashing, materials research, and sample preparation. Contact us today to enhance your lab's efficiency and data integrity!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO