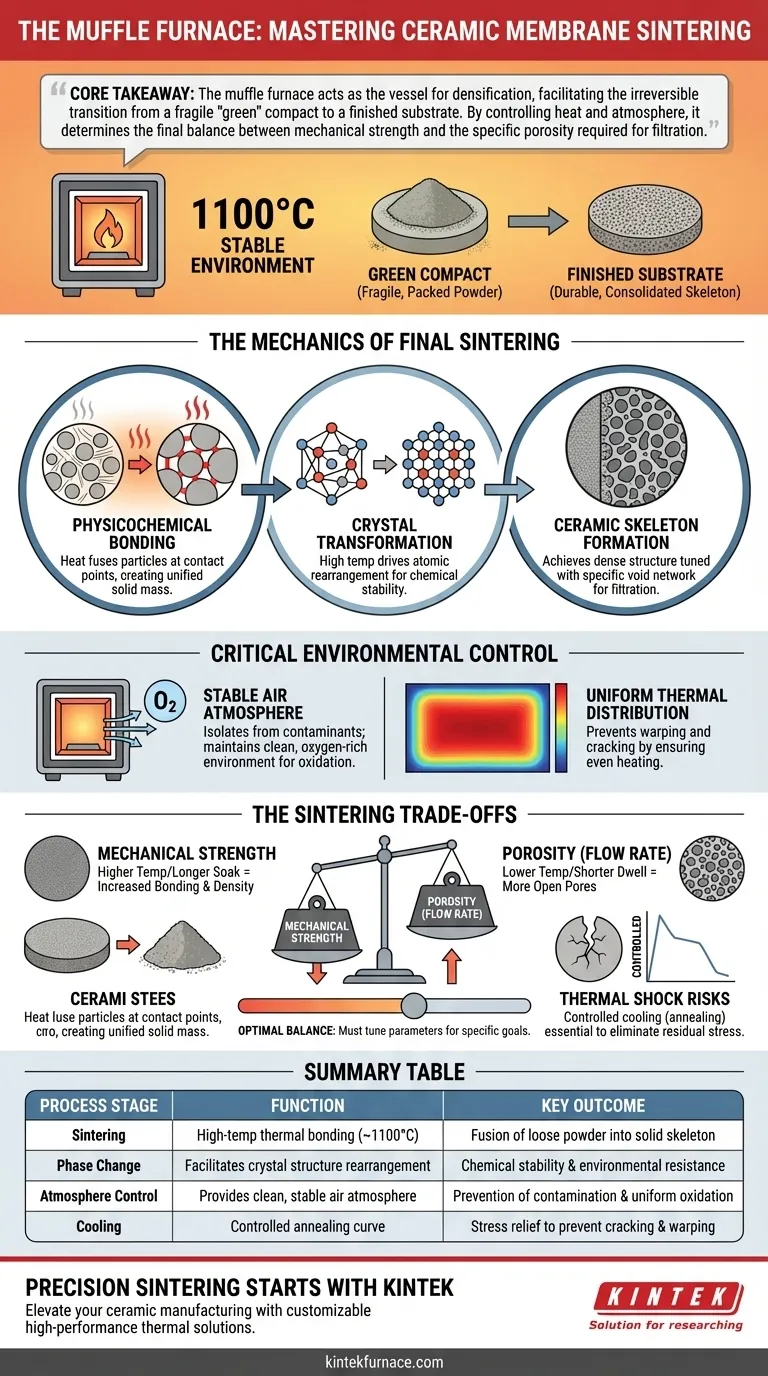

The primary function of a high-temperature muffle furnace in this stage is to execute the critical sintering process. Specifically, it exposes the ceramic material to a stable, high-temperature environment (typically around 1100°C) within an air atmosphere. This thermal treatment triggers the physicochemical bonding and crystal transformation required to convert loose powder particles into a consolidated, durable ceramic skeleton.

Core Takeaway The muffle furnace acts as the vessel for densification, facilitating the irreversible transition from a fragile "green" compact to a finished substrate. By controlling heat and atmosphere, it determines the final balance between mechanical strength and the specific porosity required for filtration.

The Mechanics of Final Sintering

The final preparation stage is not merely about drying or hardening; it is about fundamentally changing the material's structure at a microscopic level.

Physicochemical Bonding

Before entering the furnace, the substrate is essentially a packed powder held together by weak forces. The muffle furnace provides the thermal energy needed to fuse these particles.

This heat initiates a reaction where the contact points between particles bond together. This transforms a collection of loose grains into a unified solid mass without melting the material completely.

Crystal Transformation

For materials like dehydroxylated kaolin, the furnace facilitates a phase change.

The high temperature drives the rearrangement of the atomic structure. This "crystal transformation" stabilizes the material chemically, ensuring it can withstand harsh operating environments later.

Formation of the Ceramic Skeleton

The ultimate goal of this stage is to create a "dense ceramic skeleton."

While the material becomes denser and stronger, the process is tuned to maintain a specific network of voids. This results in a porous structure that allows fluids to pass through while retaining enough structural integrity to serve as a membrane substrate.

The Role of Environmental Control

A muffle furnace is distinct because of its ability to isolate the payload and control the heating environment precisely.

Stability in an Air Atmosphere

The primary reference highlights that this process occurs in an air atmosphere.

The muffle design isolates the ceramic from direct fuel combustion contaminants while maintaining a clean, oxygen-rich environment. This is essential for facilitating necessary oxidation reactions and ensuring the purity of the final ceramic phase.

Uniform Thermal Distribution

High-performance muffle furnaces are designed to provide exceptionally uniform heating.

Uniformity is critical during sintering to prevent warping or cracking. If one part of the substrate heats faster than another, differential shrinkage occurs, destroying the membrane's structural integrity.

Understanding the Trade-offs

While the muffle furnace is essential, the sintering process involves a delicate balance of competing physical properties.

Porosity vs. Mechanical Strength

The most critical trade-off is between how porous the membrane is and how strong it is.

Higher temperatures or longer soak times in the furnace generally increase bonding, making the substrate stronger. However, this increased densification reduces porosity, potentially limiting the flow rate of the final filter. You cannot maximize both simultaneously; the furnace parameters must be tuned to find the optimal middle ground.

Thermal Shock Risks

While the heating phase is critical, the cooling phase (annealing) is equally important.

If the furnace cools the substrate too rapidly after sintering, residual internal stresses can form. This can lead to immediate fracture or latent weaknesses that cause failure during operation. A high-quality muffle furnace facilitates a controlled cooling curve to eliminate these stresses.

Optimizing the Sintering Cycle

To achieve the best results with your ceramic membrane substrates, you must align the furnace's operation with your specific material goals.

- If your primary focus is mechanical durability: Ensure the furnace reaches the upper limits of the sintering temperature range (e.g., 1100°C) to maximize particle bonding and skeleton density.

- If your primary focus is high filtration flux (porosity): Carefully limit the dwell time at peak temperature to prevent over-densification, ensuring the pore structure remains open.

The high-temperature muffle furnace is the definitive tool that bridges the gap between raw potential and a functional, high-performance ceramic technology.

Summary Table:

| Process Stage | Function of Muffle Furnace | Key Material Outcome |

|---|---|---|

| Sintering | High-temp thermal bonding (approx. 1100°C) | Fusion of loose powder into a solid skeleton |

| Phase Change | Facilitates crystal structure rearrangement | Chemical stability and environmental resistance |

| Atmosphere Control | Provides clean, stable air atmosphere | Prevention of contamination and uniform oxidation |

| Cooling | Controlled annealing curve | Stress relief to prevent cracking and warping |

Precision Sintering Starts with KINTEK

Elevate your ceramic manufacturing with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific temperature and atmospheric requirements.

Whether you need to maximize filtration porosity or ensure structural mechanical strength, our furnaces provide the uniform thermal distribution essential for perfect substrate densification.

Ready to optimize your production? Contact our technical team today to find the ideal high-temp furnace for your laboratory or industrial needs.

Visual Guide

References

- Viktor Kurylenko, Tetiana Dontsova. ПЕРСПЕКТИВИ ВИКОРИСТАННЯ ТЕХНОЛОГІЇ 3D ДРУКУ DLP ДЛЯ ВИРОБНИЦТВА МЕМБРАННИХ КЕРАМІЧНИХ МОДУЛІВ. DOI: 10.15421/jchemtech.v33i2.317663

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the process logic of a muffle furnace for tungsten oxynitride thin films? Optimize Your Thermal Cycle

- How does a muffle furnace compare to other types of laboratory melting furnaces? Discover the Best Fit for Your Lab

- How are muffle furnaces manufactured? Discover Precision Engineering for Your Lab

- How does a muffle furnace control the atmosphere around the sample? Achieve Precise Material Processing

- What are the common applications of a muffle furnace? Unlock Precise Heat Treatment for Your Lab

- What temperature range can a standard muffle furnace achieve? Find Your Ideal Heat Range

- What role do muffle furnaces play in materials research? Unlock Precise Heat Treatment for Your Lab

- What makes muffle furnaces suitable for high-temperature applications? Achieve Clean, Controlled Heat for Purity