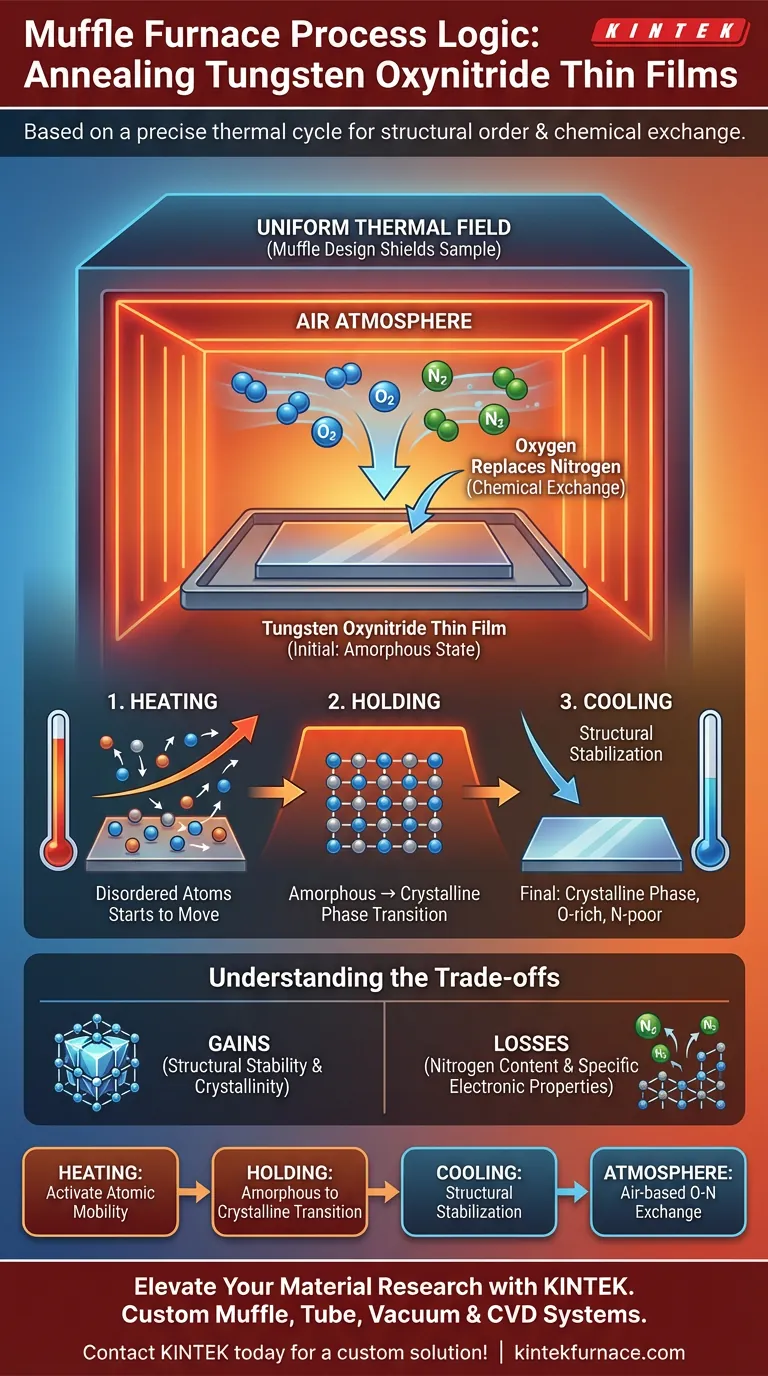

The process logic of a muffle furnace relies on a precisely programmed thermal cycle designed to impose structural order on a disordered material. Specifically, for tungsten oxynitride thin films, the furnace executes a sequence of heating, constant temperature holding, and controlled cooling to fundamentally alter the film's physical and chemical state.

Core Takeaway The muffle furnace functions as a transformation chamber that converts tungsten oxynitride films from an amorphous state to a crystalline phase using a uniform thermal field. Crucially, this process leverages an air environment to facilitate a chemical exchange where atmospheric oxygen replaces nitrogen atoms, directly impacting the film's electrochromic performance.

The Mechanics of the Thermal Cycle

Establishing the Thermal Field

The primary mechanism of the muffle furnace is the creation of a uniform thermal field. Unlike direct heating methods, the muffle design shields the sample from direct flame or heating elements, ensuring the thin film is exposed to even, radiant heat. This uniformity is critical for preventing stress fractures or uneven crystallization across the film surface.

The Three-Stage Sequence

The process logic follows a strict linear progression: heating, holding, and cooling. The "holding" phase is particularly vital, as it provides the necessary time for the thermal energy to permeate the material and activate the atomic rearrangement required for phase transition.

Structural and Chemical Transformation

From Amorphous to Crystalline

Initially, the tungsten oxynitride film exists in an amorphous state, where its atomic structure is disordered. The thermal energy provided by the furnace facilitates atomic mobility. This allows the atoms to rearrange themselves into a structured, repetitive lattice, transforming the material into a crystalline phase.

The Air Annealing Effect

Unlike vacuum or inert gas furnaces, a muffle furnace typically operates with an air atmosphere. During the annealing of tungsten oxynitride, this environment is not passive.

Oxygen-Nitrogen Exchange

The process logic relies on the chemical interaction between the film and the environment. As the temperature rises, oxygen from the air replaces nitrogen atoms within the film. This stoichiometric change is a deliberate part of the treatment to study how composition shifts affect thermal stability.

Understanding the Trade-offs

Composition vs. Crystallinity

The use of a muffle furnace involves a specific trade-off. While you gain high crystallinity and structural stability, you inevitably alter the chemical composition of the film.

Loss of Nitrogen Content

By annealing in air, you are actively reducing the nitrogen content of the tungsten oxynitride. If your goal is to maintain high nitrogen levels for specific electronic properties, a standard air-filled muffle furnace may be counterproductive compared to a vacuum or nitrogen-rich tube furnace.

Making the Right Choice for Your Goal

The "logic" of the muffle furnace is best applied when you need to stabilize the material structure while understanding the effects of oxidation.

- If your primary focus is Structural Stability: The muffle furnace is ideal for converting amorphous films into robust crystalline structures through uniform heating.

- If your primary focus is Electrochromic Research: Use this process to observe how the replacement of nitrogen with oxygen influences the color-changing capabilities of the device.

Ultimately, the muffle furnace acts as both a structural organizer and a chemical reactor, using heat and air to finalize the properties of your thin film.

Summary Table:

| Process Phase | Action | Transformation Goal |

|---|---|---|

| Heating | Uniform radiant heat application | Activation of atomic mobility |

| Holding | Constant temperature maintenance | Amorphous to crystalline phase transition |

| Cooling | Controlled temperature reduction | Structural stabilization of the lattice |

| Atmosphere | Air-based oxygen-nitrogen exchange | Chemical stoichiometric modification |

Elevate Your Material Research with KINTEK

Maximize the potential of your thin film applications with precision thermal technology. KINTEK provides industry-leading, customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed for the rigorous demands of modern laboratories. Whether you are performing air annealing for structural stability or require inert environments for nitrogen retention, our expert R&D and manufacturing teams deliver the high-temperature solutions you need.

Ready to refine your annealing process? Contact KINTEK today for a custom furnace solution!

Visual Guide

References

- Insaf F. Malikov, Л. Р. Тагиров. Anion Doping of Tungsten Oxide with Nitrogen: Reactive Magnetron Synthesis, Crystal Structure, Valence Composition, and Optical Properties. DOI: 10.3390/cryst14020109

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

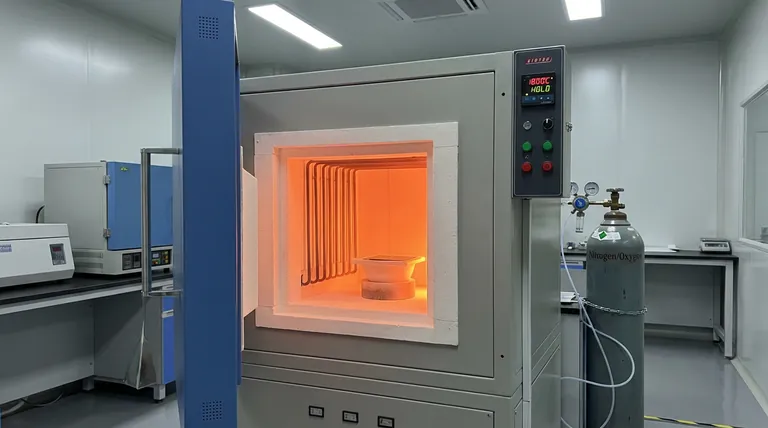

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What should be avoided when operating a muffle furnace? Key Safety Tips to Prevent Damage and Hazards

- What is the purpose of a high-temperature muffle furnace for rare earth oxalate calcination? Achieve High-Purity REOs

- What are the key functional features of a modern muffle furnace? Precision, Safety, and Efficiency for Your Lab

- What thermal processes can be performed using Box Furnaces? Unlock Versatile Heat Treatment Solutions

- What is the role of a muffle furnace in the final formation of a composite photoanode? Master Heterojunction Synthesis

- What is the core role of a laboratory muffle furnace in rice husk-based biochar? Master Your Pyrolysis Process

- What is the core function of a high-temperature muffle furnace in silver nanoparticle circuits? Optimize Conductivity

- What are the installation and maintenance benefits of electric furnaces? Achieve Simpler, Lower-Cost Heating