At its core, a modern muffle furnace is an advanced thermal processing instrument defined by its ability to deliver precise, high-temperature heating within a chamber that is isolated from direct heat sources and contaminants. Key functional features include sophisticated programmable controls for automating complex temperature cycles, rapid heating and cooling capabilities, and a suite of integrated safety systems that protect both the operator and the sample.

The evolution of the muffle furnace is a story of moving from a simple heated box to a sophisticated, digitally-controlled instrument. The defining features of a modern unit are not just about its ability to get hot, but its capacity to do so with exceptional accuracy, repeatability, and operational efficiency.

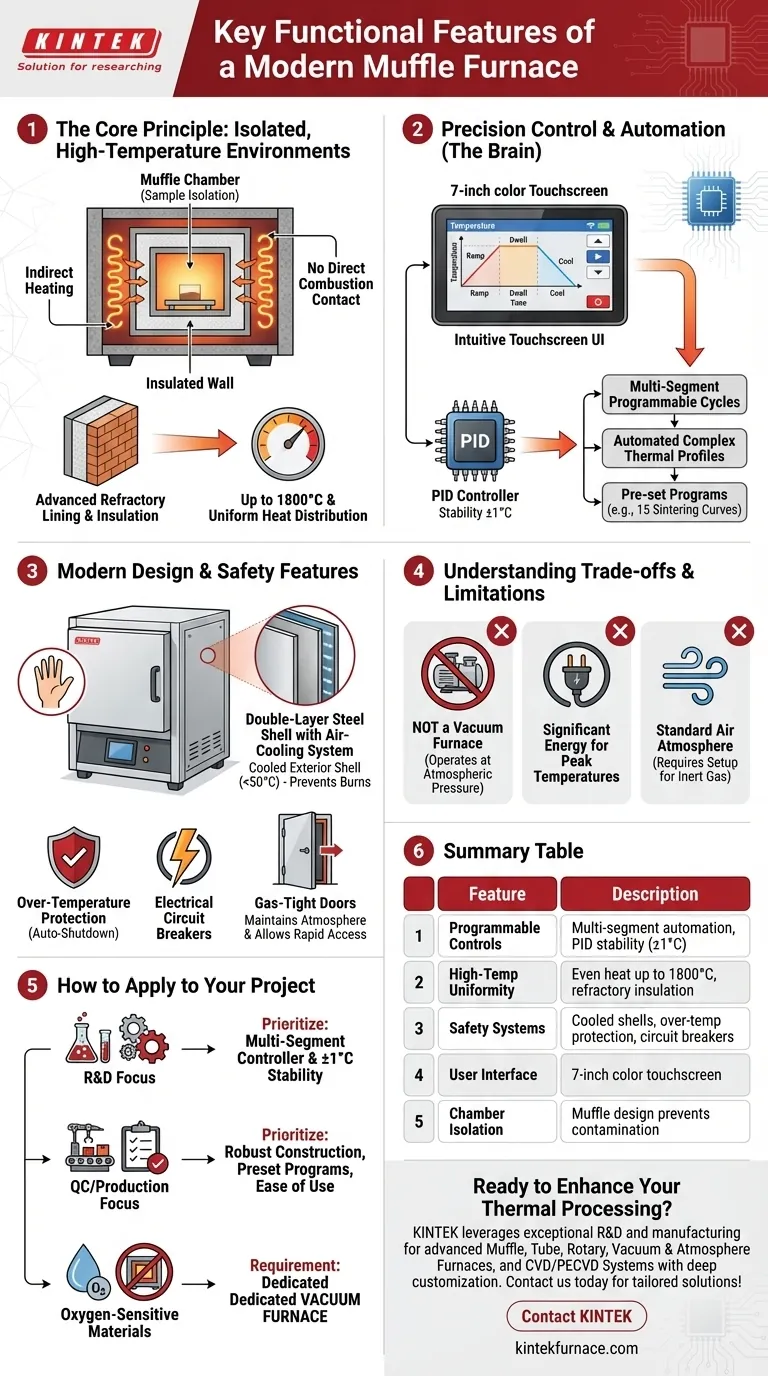

The Core Principle: Isolated, High-Temperature Environments

The fundamental value of a muffle furnace comes from its unique chamber design, which is the foundation for its most critical functions.

The "Muffle" Chamber Explained

A muffle furnace isolates the material being heated from the byproducts of fuel combustion or from direct contact with the heating elements. This creates a clean, controlled environment free from contamination.

Heat is transferred into the chamber indirectly, typically through radiation or convection from high-temperature coils embedded within insulated walls.

Achieving High Temperatures and Uniformity

Modern furnaces utilize advanced refractory brick linings and insulation to minimize heat loss and enable extremely high operating temperatures, often reaching up to 1800°C.

The design ensures that heat is distributed evenly throughout the chamber, preventing hot spots and ensuring the entire sample is processed under the same thermal conditions.

Precision Control and Automation

The "brain" of a modern furnace is its controller. This is what transforms it from a simple oven into a precise scientific instrument.

Programmable Temperature Cycles

Advanced units feature multi-segment programmable controllers, allowing users to design and automate complex thermal profiles. For example, a 30-segment program can manage precise ramp-up rates, dwell times at specific temperatures, and controlled cooling stages.

Intuitive User Interfaces

Complex programming is made accessible through modern user interfaces, such as a 7-inch color touchscreen. This allows for easy input, monitoring of the furnace status in real-time, and storage of custom programs.

Unwavering Temperature Stability

Through PID (Proportional-Integral-Derivative) controllers and high-quality sensors, modern furnaces can maintain a set temperature with remarkable stability, often within a tolerance of ±1°C. This is critical for processes where temperature accuracy dictates the outcome.

Pre-set Programs for Common Tasks

To streamline workflow, many furnaces come with pre-loaded programs for common applications. Having 15 preset sintering curves, for instance, allows an operator to run a standard process with minimal setup.

Understanding the Trade-offs and Limitations

While highly capable, a muffle furnace is not a universal solution. Understanding its limitations is key to using it effectively.

The Critical Vacuum Limitation

A muffle furnace is not a vacuum furnace. It is designed to operate at or near atmospheric pressure.

Applications requiring the removal of air and other gases to prevent oxidation or contamination—such as the heat treatment of highly sensitive metals—mandate the use of a dedicated vacuum furnace.

Energy Efficiency vs. Peak Temperature

While designed to be energy-efficient, reaching and maintaining temperatures near 1800°C requires a significant amount of power. The "energy-efficient" label refers to the superior insulation and modern controls that minimize waste compared to older designs, not a lack of energy consumption.

Chamber Atmosphere Control

Standard muffle furnaces heat samples in an air atmosphere. While some models feature gas-tight doors to maintain a specific inert gas environment introduced by the user, they do not inherently create or regulate this atmosphere.

Modern Design and Safety Features

Modern engineering focuses heavily on protecting the user, the sample, and the equipment itself.

Operator Safety: The Cooled Shell

Many furnaces feature a double-layer steel shell with an integrated air-cooling system. This design keeps the exterior surface temperature low (often below 50°C), even when the interior is at its peak temperature, preventing accidental burns.

System Protection: Alarms and Breakers

Essential safety features are built-in to prevent catastrophic failure. Over-temperature protection automatically shuts the furnace down if it exceeds a set limit, while electrical circuit breakers protect against power surges.

Process Integrity: Gas-Tight Doors

For applications sensitive to atmospheric changes, gas-tight doors are a key feature. They allow for rapid loading and unloading of samples while helping to maintain a consistent positive pressure inside the chamber.

How to Apply This to Your Project

Choosing the right features depends entirely on your primary goal.

- If your primary focus is materials research and development (R&D): Prioritize a furnace with an advanced, multi-segment programmable controller and documented temperature stability (e.g., ±1°C) for repeatable experiments.

- If your primary focus is routine quality control or production (e.g., ashing): Look for robust construction, preset programs for your specific tasks, and features that enhance ease of use, like intuitive touchscreens.

- If your primary focus is heat-treating oxygen-sensitive materials: Recognize that a muffle furnace is the wrong tool, and your needs require a dedicated vacuum furnace.

Understanding these key functional features empowers you to select an instrument that serves as a precise and reliable tool for your specific application.

Summary Table:

| Feature | Description |

|---|---|

| Programmable Controls | Multi-segment automation for complex temperature cycles with PID stability (±1°C) |

| High-Temperature Uniformity | Even heat distribution up to 1800°C with refractory insulation |

| Safety Systems | Cooled shells, over-temperature protection, and circuit breakers |

| User Interface | 7-inch color touchscreen for easy programming and monitoring |

| Chamber Isolation | Muffle design prevents contamination from heating elements |

| Limitations | Not suitable for vacuum applications; operates at atmospheric pressure |

Ready to enhance your laboratory's thermal processing with a tailored muffle furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs precisely. Contact us today to discuss how our high-temperature furnace solutions can boost your efficiency and accuracy!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites