To safely operate a muffle furnace, you must avoid introducing any material that can cause rapid pressure changes, chemical reactions, or thermal shock. The most critical things to avoid are flammable or explosive substances, liquids of any kind, and exceeding the furnace's maximum temperature rating. Furthermore, never open the furnace door at high temperatures (typically above 600°C) to prevent damaging the unit and creating a safety hazard.

A muffle furnace is designed to create a highly controlled, isolated heating environment. Safe operation hinges on one core principle: respecting the integrity of that environment by avoiding any action or material that introduces instability.

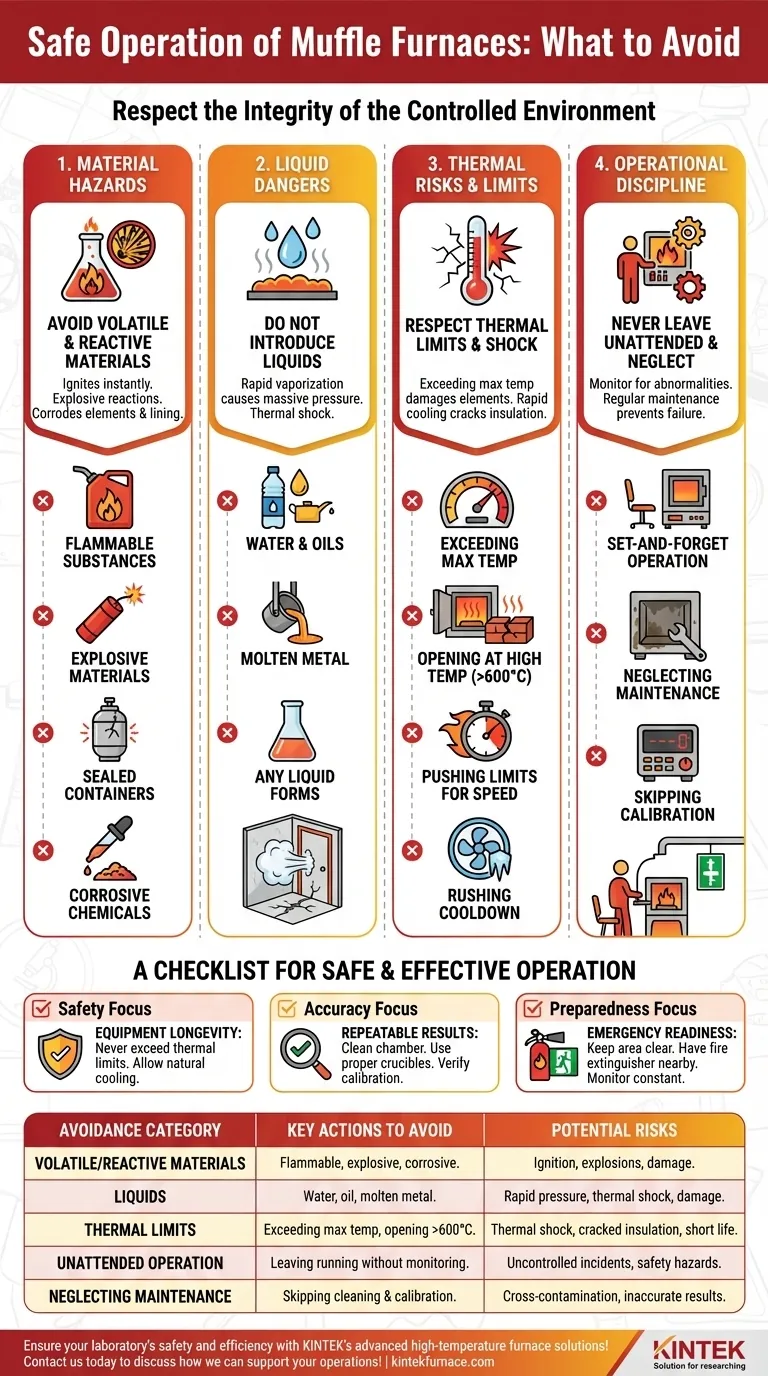

Core Safety Principles: Preventing Catastrophic Failures

The rules of furnace operation are not arbitrary; they are based on preventing thermal, chemical, and pressure-related failures that can destroy the equipment and endanger the operator.

Avoid Volatile and Reactive Materials

The extreme heat inside a furnace chamber can instantly ignite flammable materials or cause explosive reactions. This includes obvious items like solvents but also any sealed containers that can build up internal pressure.

Corrosive substances can release fumes that attack the furnace's heating elements and internal refractory lining, leading to premature failure.

Do Not Introduce Liquids

Liquids like water or oil must never be placed inside the furnace. At high temperatures, they will vaporize almost instantly, causing a massive and rapid increase in pressure that can damage the furnace door, seals, and insulation.

Pouring molten metal directly into the chamber is also forbidden, as it creates an extreme thermal shock that can crack the furnace floor.

Respect Thermal Limits and Shock

Every furnace has a maximum operating temperature that should never be exceeded. Doing so will permanently damage the heating elements and insulation.

Even operating continuously at the maximum rated temperature will significantly shorten the furnace's lifespan. It is best to operate at least 50-100°C below the maximum for longevity.

Opening the door at high temperatures (above 600°C) causes thermal shock, a rapid temperature change that can crack the ceramic insulation or even shatter your sample. Always allow the furnace to cool down slowly and naturally.

Never Leave the Furnace Unattended

A muffle furnace is not a "set-and-forget" appliance. You must be present to monitor its operation.

If you observe any abnormalities, such as unusual sounds, pressure changes, or rapid temperature fluctuations, cut the power immediately and investigate once it has safely cooled.

Understanding the Trade-offs

Many operational mistakes stem from a desire for speed, but these shortcuts often lead to damaged equipment or inaccurate results.

The Pitfall of Rushing the Cooldown

The temptation to open the furnace door to speed up the cooling process is a common error. This action directly risks thermal shock, which can crack the expensive refractory brick lining.

A cracked lining compromises the furnace's heating efficiency and requires costly repairs. The few hours saved are not worth the risk of damaging the equipment.

The Problem with Pushing Temperature Limits

Running the furnace at its absolute maximum temperature might complete a process faster, but it comes at a steep cost. This practice dramatically accelerates the degradation of the heating elements and insulation.

This is a direct trade-off between short-term speed and the long-term reliability and lifespan of the furnace. For consistent results and minimal downtime, operate below the absolute peak temperature.

Neglecting Maintenance and Cleanliness

Failing to regularly clean the furnace chamber can lead to cross-contamination. Residue from a previous run can become volatile and react with a new sample, skewing your results.

Similarly, neglecting to check the temperature controller's calibration can lead to experiments being run at the wrong temperature, rendering the results useless.

A Checklist for Safe and Effective Operation

Your primary goal should dictate your operational focus. Use these points as a guide for your specific application.

- If your primary focus is safety and equipment longevity: Never exceed thermal limits, avoid all volatile or reactive materials, and always allow the furnace to complete its cooling cycle without intervention.

- If your primary focus is accurate and repeatable results: Ensure the furnace chamber is clean before each use, use proper high-temperature crucibles for your samples, and periodically verify the temperature controller's calibration.

- If your primary focus is emergency preparedness: Always keep the area around the furnace clear of clutter and flammables, ensure a suitable fire extinguisher is nearby, and never leave the furnace running unattended.

Understanding and respecting these operational boundaries transforms the furnace from a potential hazard into a precise and reliable scientific instrument.

Summary Table:

| Avoidance Category | Key Actions to Avoid | Potential Risks |

|---|---|---|

| Volatile/Reactive Materials | Introducing flammable, explosive, or corrosive substances | Ignition, explosions, damage to heating elements and lining |

| Liquids | Placing water, oil, or molten metal inside | Rapid pressure changes, thermal shock, structural damage |

| Thermal Limits | Exceeding max temperature or opening door above 600°C | Thermal shock, cracked insulation, reduced lifespan |

| Unattended Operation | Leaving furnace running without monitoring | Uncontrolled incidents, safety hazards |

| Neglecting Maintenance | Skipping cleaning and calibration checks | Cross-contamination, inaccurate results, equipment failure |

Ensure your laboratory's safety and efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable muffle, tube, rotary, vacuum, atmosphere furnaces, and CVD/PECVD systems. Our strong deep customization capability precisely meets your unique experimental needs, enhancing performance and longevity. Contact us today to discuss how we can support your operations!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production