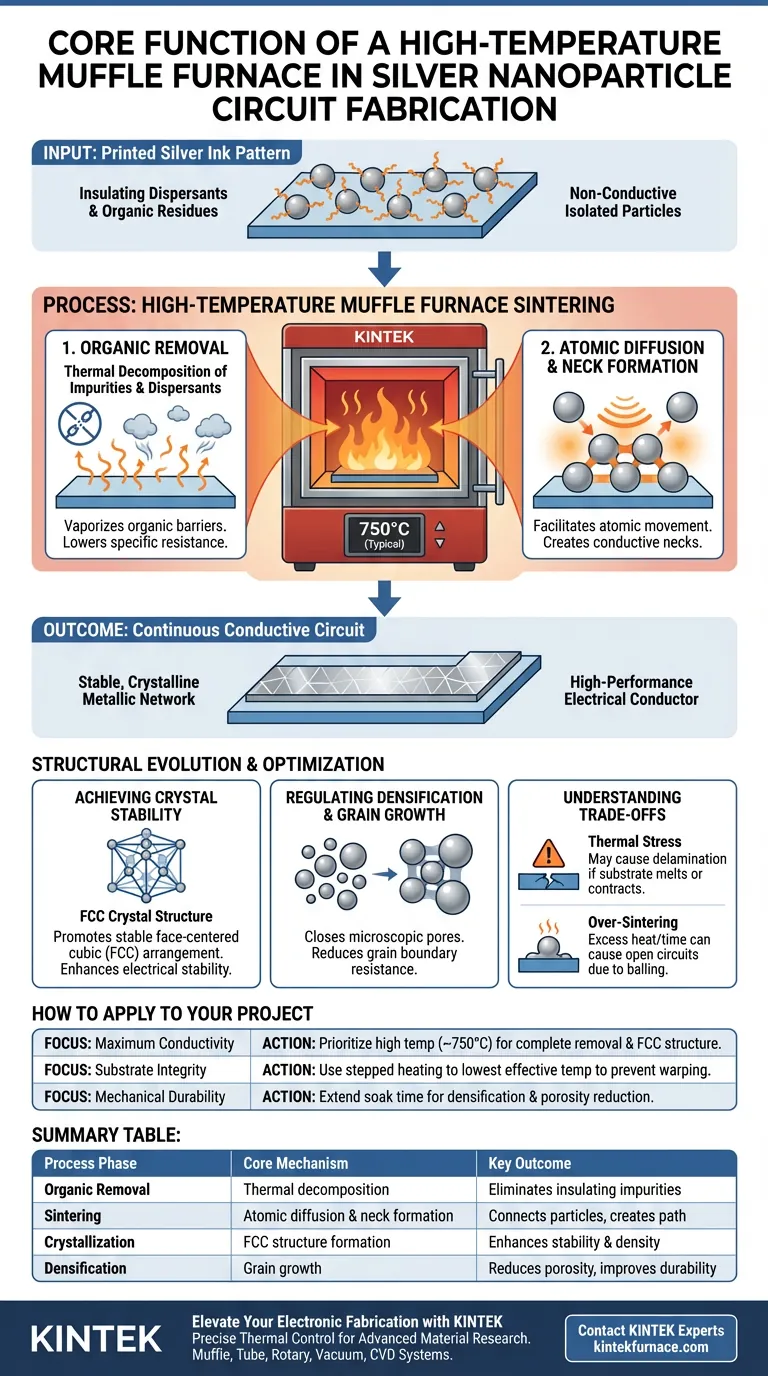

The core function of a high-temperature muffle furnace is to facilitate the sintering process, which transforms isolated silver nanoparticles into a continuous, conductive circuit. It achieves this by providing a high-temperature environment (typically reaching 750°C) to thermally decompose insulating dispersants and organic residues. This allows the silver atoms to diffuse, creating physical "necks" between particles that establish a low-resistance path for electricity.

The muffle furnace serves as the critical transition point where a printed pattern of silver ink becomes a functional electronic component. By managing the thermal decomposition of impurities and promoting atomic diffusion, the furnace ensures the formation of a stable, crystalline metallic network.

The Mechanics of Thermal Transformation

Removing the Organic Barrier

Before sintering, silver nanoparticles are coated in dispersants and organic residues that prevent them from clumping in liquid form. These coatings are essentially insulators that block the flow of electricity between the particles.

The muffle furnace uses extreme heat to trigger thermal decomposition, vaporizing these organic chains and biological impurities. This step is vital because even trace amounts of leftover carbon can significantly increase the circuit's specific resistance.

Atomic Diffusion and Neck Formation

As the temperature rises, the silver atoms at the surface of the nanoparticles become highly mobile. This thermal energy facilitates the movement of atoms across particle boundaries, leading to the formation of physical bridges known as necks.

These necks merge the individual particles into a continuous conductive network. This structural change is what allows the material to transition from a collection of isolated points to a high-performance electrical conductor.

Structural Evolution and Crystallization

Achieving Crystal Stability

The high-heat environment of the furnace does more than just melt surfaces; it improves the internal crystallization of the silver. Specifically, it promotes the formation of a stable face-centered cubic (FCC) crystal structure.

This FCC arrangement is the most efficient and stable configuration for silver atoms in a conductive circuit. A well-defined crystal structure ensures the circuit remains durable and maintains consistent electrical properties over time.

Regulating Densification and Grain Growth

Controlled heating manages particle densification, which is the process of closing the microscopic pores between nanoparticles. This reduction in porosity makes the final circuit more mechanically robust and less prone to failure.

During this phase, grain growth occurs as smaller silver crystals merge into larger ones. This reduces the number of grain boundaries, which are areas of higher electrical resistance, further improving the overall conductivity of the silver trace.

Understanding the Trade-offs

Thermal Stress and Substrate Limitations

While high temperatures (750°C) are excellent for silver crystallization, they exceed the melting points of many common substrates like plastics or low-grade glass. You must ensure that your substrate's thermal stability aligns with the sintering temperature required for the silver ink.

Rapid cooling after the furnace cycle can also introduce thermal stress. If the silver film and the substrate contract at different rates, it may lead to delamination or micro-cracking in the circuit.

Over-Sintering and Discontinuity

Excessive time or temperature in the muffle furnace can lead to over-sintering, where silver particles migrate too aggressively. In extreme cases, this causes the silver to "ball up" due to surface tension, breaking the continuous line and creating an open circuit.

Finding the balance between removing all organic by-products and maintaining the geometric integrity of the circuit is the primary challenge of the thermal cycle.

How to Apply This to Your Project

When integrating a high-temperature muffle furnace into your fabrication workflow, your approach should be dictated by your specific performance requirements.

- If your primary focus is Maximum Conductivity: Prioritize higher temperatures near 750°C to ensure complete organic removal and a stable face-centered cubic crystal structure.

- If your primary focus is Substrate Integrity: Utilize a stepped heating profile to reach the lowest effective sintering temperature, preventing the substrate from warping or melting.

- If your primary focus is Mechanical Durability: Focus on the densification phase by extending the "soak" time at peak temperature to minimize internal porosity and grain boundary resistance.

A precisely controlled thermal cycle is the definitive factor in evolving silver nanoparticles from a simple ink into a high-performance electronic medium.

Summary Table:

| Process Phase | Core Mechanism | Key Outcome |

|---|---|---|

| Organic Removal | Thermal decomposition | Eliminates insulating dispersants & impurities |

| Sintering | Atomic diffusion & neck formation | Connects particles into a continuous conductive path |

| Crystallization | FCC structure formation | Enhances electrical stability and crystal density |

| Densification | Grain growth | Reduces porosity for superior mechanical durability |

Elevate Your Electronic Fabrication with KINTEK

Precise thermal control is the difference between a failed trace and a high-performance circuit. Backed by expert R&D and manufacturing, KINTEK offers high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet the rigorous demands of silver nanoparticle sintering and advanced material research.

Whether you are targeting maximum conductivity or substrate-sensitive processing, our laboratory high-temperature furnaces provide the uniformity and reliability your project requires.

Ready to optimize your sintering workflow?

Contact KINTEK experts today for a custom solution

Visual Guide

References

- Hyeong-Jin Park, Seung Jae Moon. Physical Characteristics of Sintered Silver Nanoparticle Inks with Different Sizes during Furnace Sintering. DOI: 10.3390/ma17050978

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does a high-temperature muffle furnace play in the pre-calcination of PZT ceramics? Essential Synthesis Guide

- What factors should be considered when purchasing a muffle furnace? Ensure Precision and Safety for Your Lab

- How does a bench-top high-temperature furnace ensure the quality of the ceramic layer? Master CCT for Ti6242 Alloy

- How do sample requirements influence the choice of a muffle furnace? Match Your Material for Accurate Results

- What is the role of a high-temperature muffle furnace in the annealing process of para-aramid fibers?

- Why are box furnaces considered essential in various industries? Discover Their Versatile Heating Solutions

- What precautions should be taken when using a muffle furnace? Essential Safety Guidelines for Lab Success

- What is the lining material of a muffle furnace? Choose the Right Refractory for Your Needs