Operating a muffle furnace is a routine task in many labs, but its safety cannot be taken for granted. The essential precautions involve wearing correct personal protective equipment (PPE), ensuring the furnace is installed in a safe environment, carefully controlling the materials you heat, and adhering to strict protocols for heating and, most importantly, cooling the chamber.

The extreme temperatures of a muffle furnace present significant thermal, electrical, and chemical hazards. Effective safety is not just a checklist but a deep understanding of how to manage this energy—preventing thermal shock, electrical faults, and uncontrolled reactions is paramount to protecting yourself, your equipment, and your results.

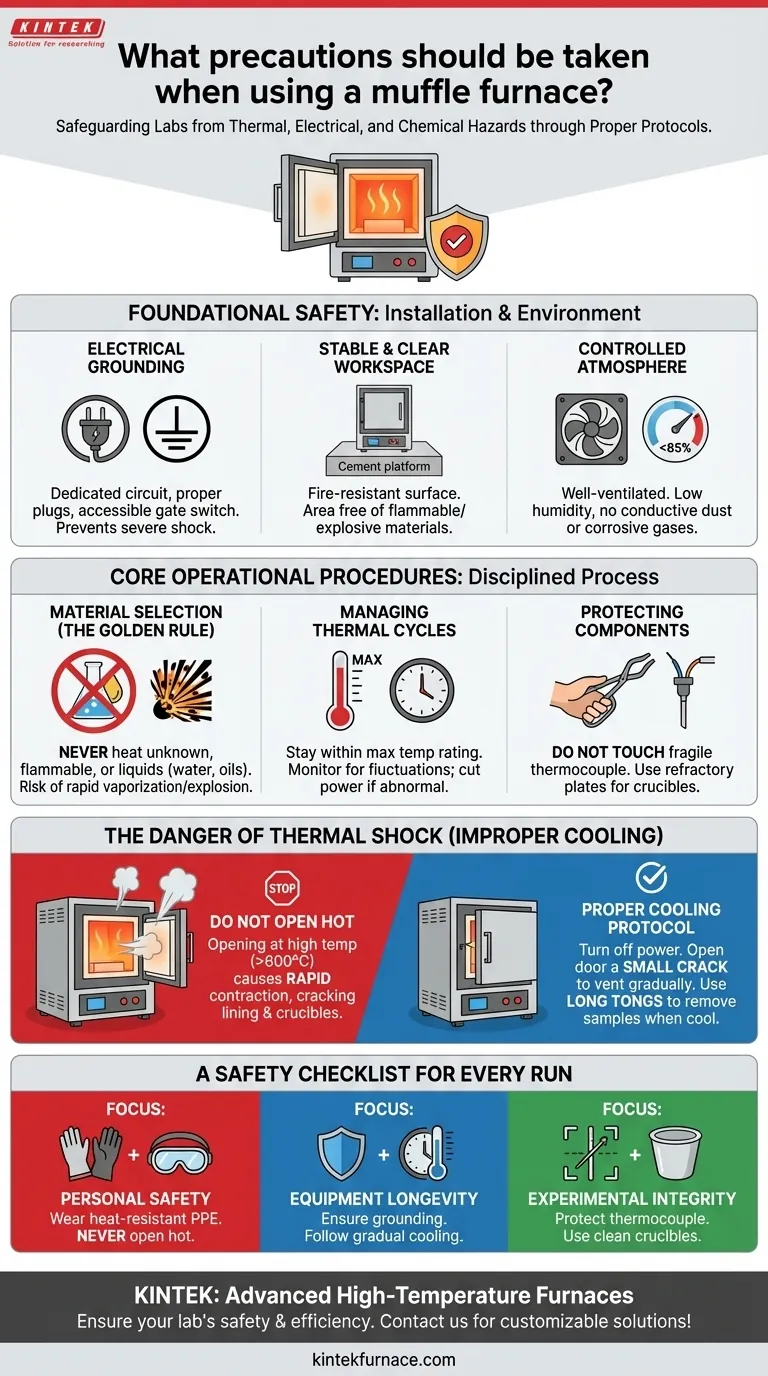

Foundational Safety: Installation and Environment

Your first line of defense is a correct and secure setup. An improper environment creates risks before the furnace is even turned on.

Electrical Grounding and Power Supply

The furnace is a high-power electrical device. Proper grounding is non-negotiable to prevent the risk of severe electric shock.

It should be connected to a dedicated circuit with the appropriate plugs, fuses, and an accessible gate or switch to control the main power. This prevents overloading and provides a way to cut power quickly in an emergency.

Stable Placement and Clear Workspace

The furnace must be placed on a stable, fire-resistant surface, such as a cement platform. This prevents tipping and ensures it can handle the operational weight and heat.

Keep the surrounding area completely free of flammable, explosive, or corrosive materials. A muffle furnace radiates intense heat, creating a significant fire hazard if combustibles are nearby.

Controlled Atmosphere and Ventilation

Operate the furnace in a well-ventilated area to dissipate heat and any potential fumes generated from your samples. The environment should have less than 85% humidity and be free of conductive dust or corrosive gases that can damage the electronics and heating elements.

Core Operational Procedures

Safe operation is a disciplined process. Every step, from loading the sample to shutdown, requires deliberate attention.

The Golden Rule of Material Selection

Never heat unknown, flammable, or explosive substances. Specifically, avoid materials containing water, oils, or other liquids.

When heated, these liquids can vaporize rapidly, causing a sudden pressure increase that can damage the furnace or even lead to a small explosion.

Managing Thermal Cycles

Always operate within the furnace's maximum temperature rating. Running it at its highest rated temperature for extended periods can shorten the life of the heating elements.

Monitor the temperature display during operation. If you notice unexpected fluctuations or abnormalities, cut the power immediately and investigate the cause.

Protecting Critical Components

When loading samples, take extreme care not to touch the thermocouple. This sensor, which extends into the chamber, is fragile at high temperatures and essential for accurate temperature control.

Use refractory plates to support your crucibles and samples. This ensures stability and protects the furnace floor.

Understanding the Pitfalls: The Danger of Thermal Shock

The most common and costly mistake when using a muffle furnace involves improper cooling. The vast temperature difference between the hot furnace and the ambient air creates a major risk.

Why You Never Open a Hot Furnace

Opening the furnace door while it is at a high temperature (e.g., above 600°C) introduces a rush of cool air. This causes thermal shock, a rapid contraction that can crack the furnace's expensive ceramic refractory lining or shatter your sample crucibles.

The Proper Cooling Protocol

After a cycle is complete, turn off the main power. Do not open the door immediately.

Instead, open the door just a small crack. This allows heat and pressure to vent gradually, letting the chamber cool down in a more controlled manner and preventing thermal shock.

Removing Your Samples

Once the furnace has cooled significantly, you can fully open the door. Always use long, heat-resistant crucible tongs to remove your items and place them on a designated cooling block.

A Safety Checklist for Every Run

Use these points to ensure a safe and effective process every time.

- If your primary focus is personal safety: Always wear heat-resistant gloves and safety goggles, and never open a hot furnace door.

- If your primary focus is equipment longevity: Prioritize a stable, grounded installation, avoid heating prohibited materials, and always follow the gradual cooling protocol to prevent thermal shock.

- If your primary focus is experimental integrity: Ensure accurate temperature calibration, protect the thermocouple from contact, and use clean, appropriate crucibles and refractory plates.

By treating the furnace with a systematic respect for its power, you ensure safe, repeatable, and successful results.

Summary Table:

| Safety Focus | Key Precautions |

|---|---|

| Personal Safety | Wear heat-resistant gloves and goggles; never open hot furnace door |

| Equipment Longevity | Ensure proper grounding; prevent thermal shock with gradual cooling |

| Experimental Integrity | Protect thermocouple; use clean crucibles; monitor temperature |

Ensure your lab's safety and efficiency with KINTEK's advanced high-temperature furnaces. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable muffle, tube, rotary, vacuum & atmosphere furnaces, and CVD/PECVD systems. Our strong deep customization capability allows us to precisely meet your unique experimental requirements while prioritizing safety features. Contact us today to discuss how our solutions can enhance your lab's performance and safety protocols!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites